Two-dimensional motor combined piston pump

A combined piston and piston pump technology, applied in piston pumps, electric components, pumps, etc., can solve problems such as large mechanical wear and motor heating, and achieve the effects of improving efficiency, reducing friction, and high power-to-weight ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

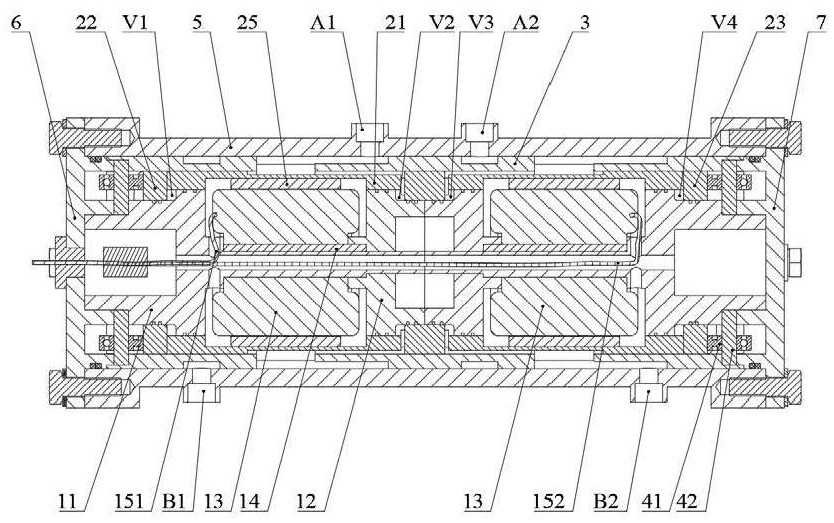

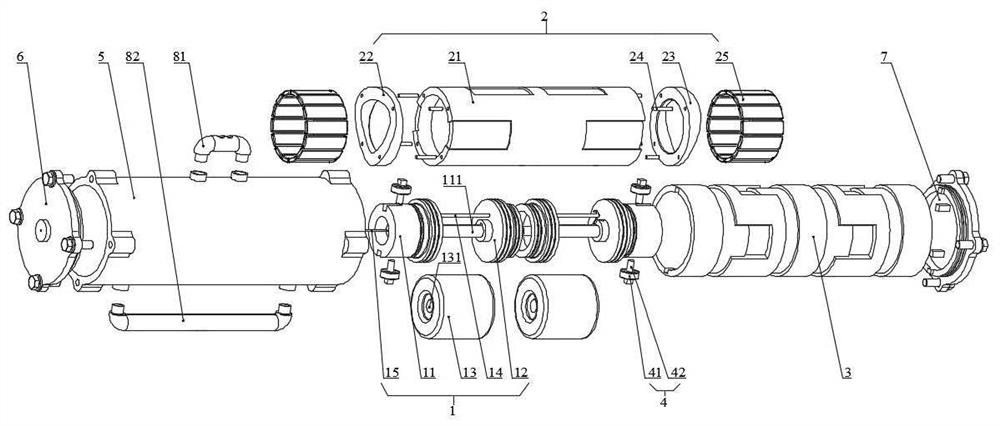

[0032] In the example of this embodiment, the motor outer rotor 2 further includes a left cam 22 and a right cam 23. One side of the cam is a convex surface, and the shape of the convex surface is determined according to the required cycle and stroke. For example, the convex surface is similar to a sine function, with peaks and valleys. If the difference is 5mm, the axial stroke of the rotor is ±2.5mm. The other side of the cam is smooth, and the end face has a pin hole, which is fixedly connected with the flow distribution rotor 21 by the pin 24, and the cams at both ends are staggered into 180° according to the crests or troughs of the convex surface.

[0033] In this embodiment, the two-dimensional piston pump part includes a flow distribution mechanism composed of a flow distribution rotor 21 and a pump body 3 . The distribution rotor 21 is axially symmetrical with respect to the middle plane, and there are eight grooves on the outer surface, of which four grooves are loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com