Atomization mechanism of electronic cigarette atomizer and electronic cigarette atomizer

An electronic cigarette atomizer and atomizing tube technology, applied in the field of electronic cigarettes, can solve the problems of rough smoke, affect people, poor smoking taste, etc., and achieve the effects of being conducive to generation, convenient for smoking, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

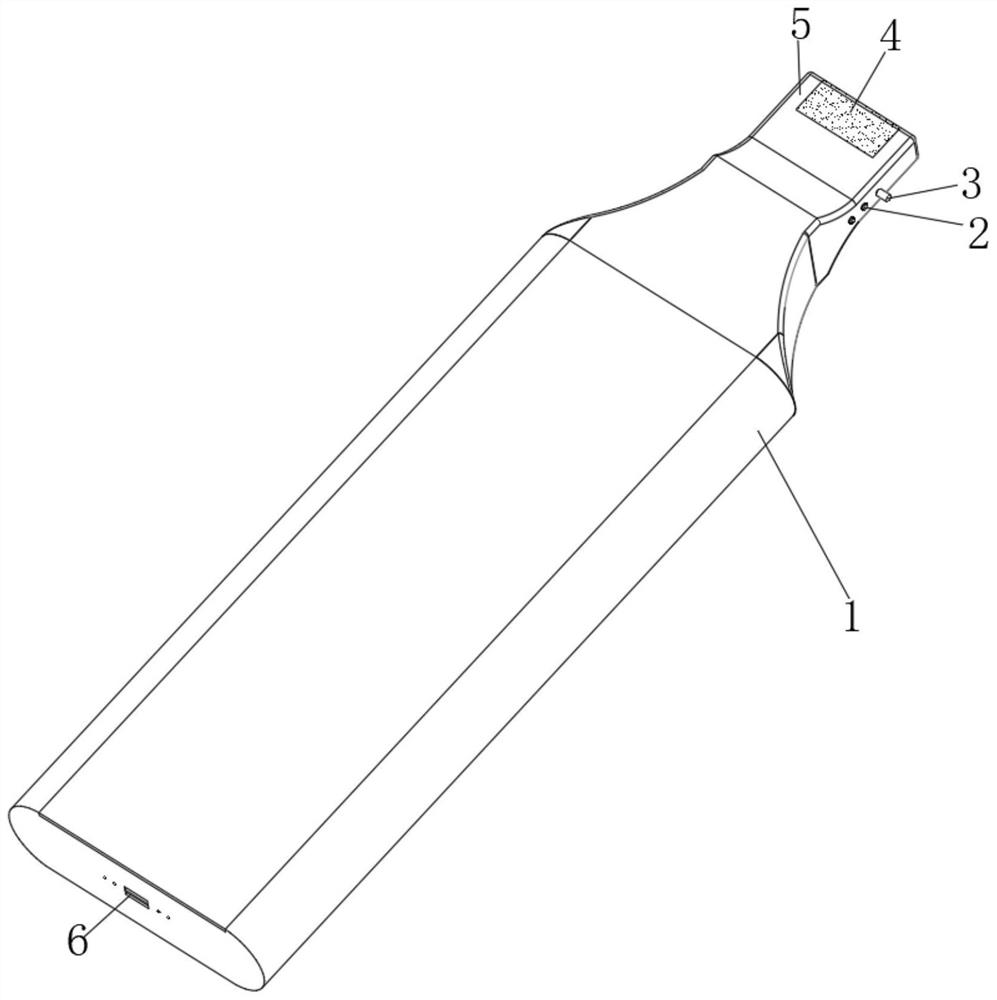

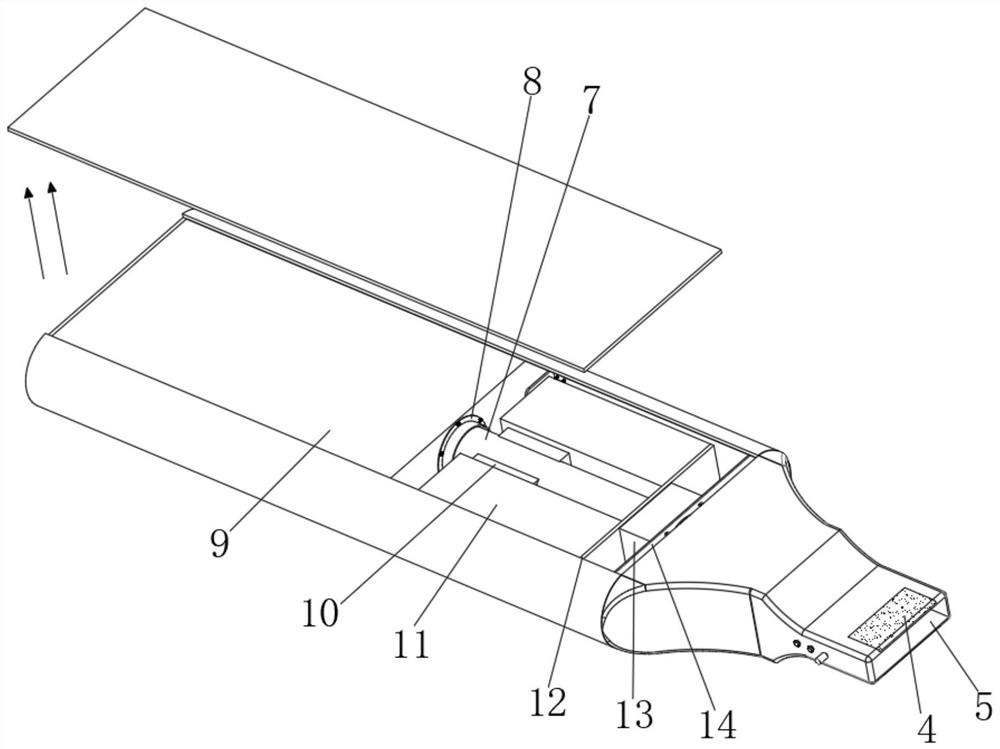

[0034] According to an embodiment of the present invention,

[0035] see Figure 1-8, an atomization mechanism of an electronic cigarette atomizer, comprising a casing 1, an oil storage tank 11 is arranged inside the casing 1, a connection box 10 is fixedly connected to one side of the oil storage tank 11, and the inside of the oil storage tank 11 contains smoke. Oil, the peripheral outer wall of the connection box 10 is fixedly connected with the atomization tube 7, one end of the atomization tube 7 is fixedly connected with the connection seat 8, one side of the connection seat 8 is provided with the heating pipe 27, the oil storage tank 11 and the connection box 10 are connected together. A rectangular groove is opened on the side, a through groove 28 is opened on one side of the atomizing tube 7, the through groove 28 is connected with the rectangular groove, the oil guiding cotton 29 is inserted into the rectangular groove, and the heating pipe 27 is inserted into the oil...

Embodiment 2

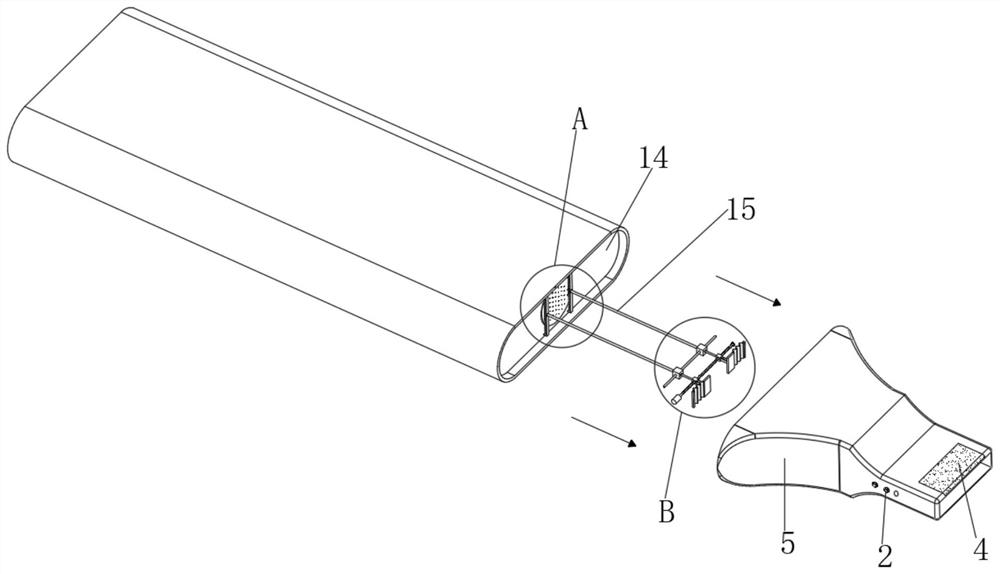

[0037] see Figure 6-7 , an atomization mechanism of an electronic cigarette atomizer, the negative pressure component includes a fixing frame 32 fixedly connected to the inner wall of the atomization tube 7, one end of the fixing frame 32 is fixedly connected with a fixing ring, and the fixing ring is fixedly connected with a motor 33, the motor The output end of 33 is provided with a shaft sleeve, the outer circumferential wall of the shaft sleeve is fixedly connected with the fan blade 30, one side of the fan blade 30 is fixedly connected with a bevel gear block 31, the oil guiding cotton 29 includes a rectangular part and a circular part, the rectangular part is inserted Connected inside the rectangular slot, the heating tube 27 passes through the inside of the circular portion, the clip assembly includes a clip hole 34 opened on one side of the second fixing plate 14, the clip hole 34 is clipped with a clip column 35, and the clip column 35 It is fixedly connected with th...

Embodiment 3

[0039] see Figure 1-5 , an electronic cigarette atomizer, a battery 9 is arranged inside the casing 1, a charging port 6 is opened on one side of the battery 9, a cigarette holder 5 is arranged on one side of the casing 1, and a control button is arranged on the outer wall of one side of the cigarette holder 5 2. The inside of the cigarette holder 5 is provided with an adjustment assembly, and the adjustment assembly includes a second connection block 21 fixedly connected to the inner wall of one side of the cigarette holder 5. One side of the second connection block 21 is fixedly connected with a folding plate 19. The height of the folding plate 19 is The inner diameter of the mouthpiece 5 is the same, the first connecting block 20 is fixedly connected to the side of the folding plate 19 away from the second connecting block 21 , and a driving assembly is provided on one side of the first connecting block 20 , and the driving assembly includes a side that is rotatably connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com