Device capable of shelling walnuts in different shapes

A walnut shell breaking technology, applied in kitchen utensils, household utensils, applications, etc., can solve the problems of incomplete shelling, walnut shell splashing, environmental damage, etc., achieve high work efficiency, prevent shell splashing, and have a wide range of practical people Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

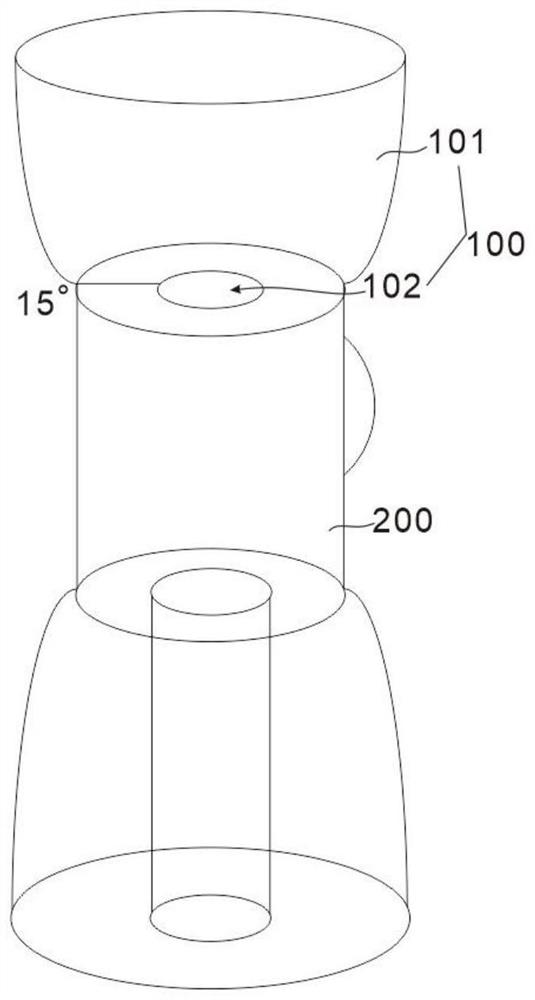

[0027] refer to figure 1 , which is the first embodiment of the present invention. This embodiment provides a device for shelling walnuts of different shapes. The device for shelling walnuts with different shapes includes a blanking assembly 100 and a shelling assembly 200. The blanking assembly 100 can cut the walnuts more quickly and prevent blocking, and then the walnuts of different shapes can be shelled and separated through the shelling assembly 200 .

[0028] Specifically, the blanking assembly 100 includes a blanking bin 101 and a blanking port 102 disposed at the bottom of the blanking bin 101 . The feeding port 102 and the bottom of the feeding bin 101 are inclined at an angle of 15°. The diameter of the feeding port 102 is adjustable, and is generally set to be larger than the horizontal area of the walnut and smaller than the longitudinal area of the walnut. A small vibration motor is installed at the bottom of the unloading bin 101, and under the action of vi...

Embodiment 2

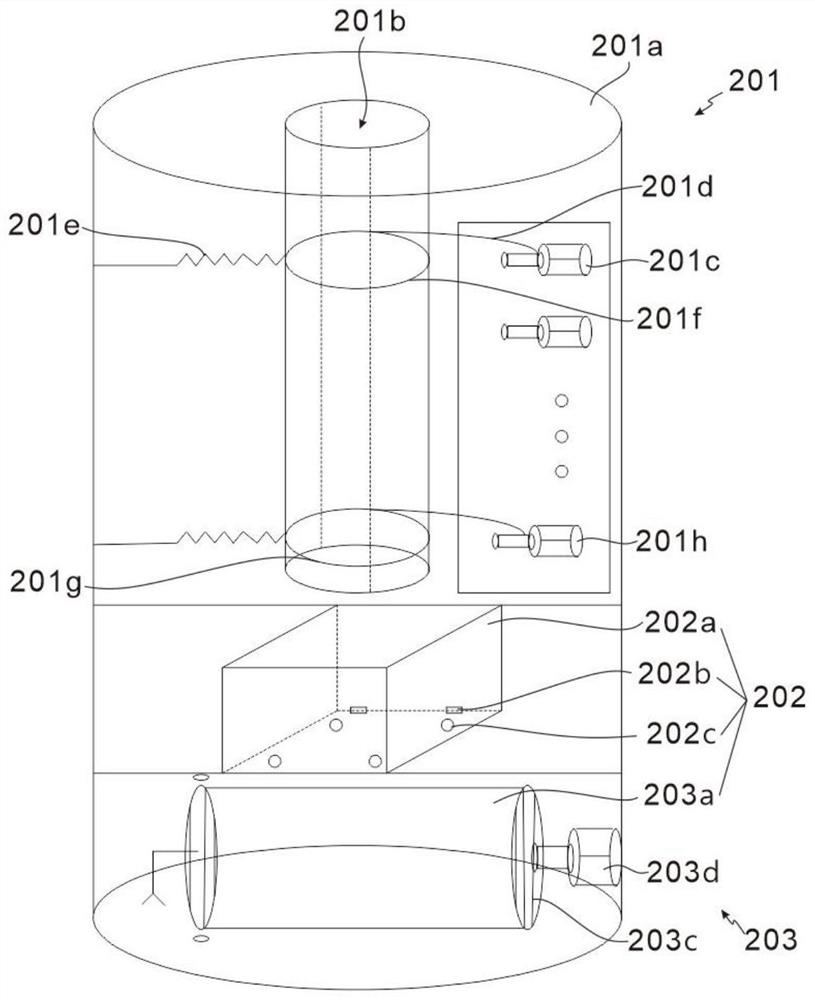

[0032] refer to Figures 2 to 5 , is the second embodiment of the present invention, which is based on the previous embodiment.

[0033] Specifically, the shell breaking member 201 includes a shelling bin 201a disposed at the bottom of the feeding port 102, and a shelling channel 201b disposed in the middle of the shelling bin 201a. The shelling channel 201b is located in the middle of the shelling bin 201a, and is in the shape of a cylindrical barrel, and three photoelectric switches are evenly distributed in its interior.

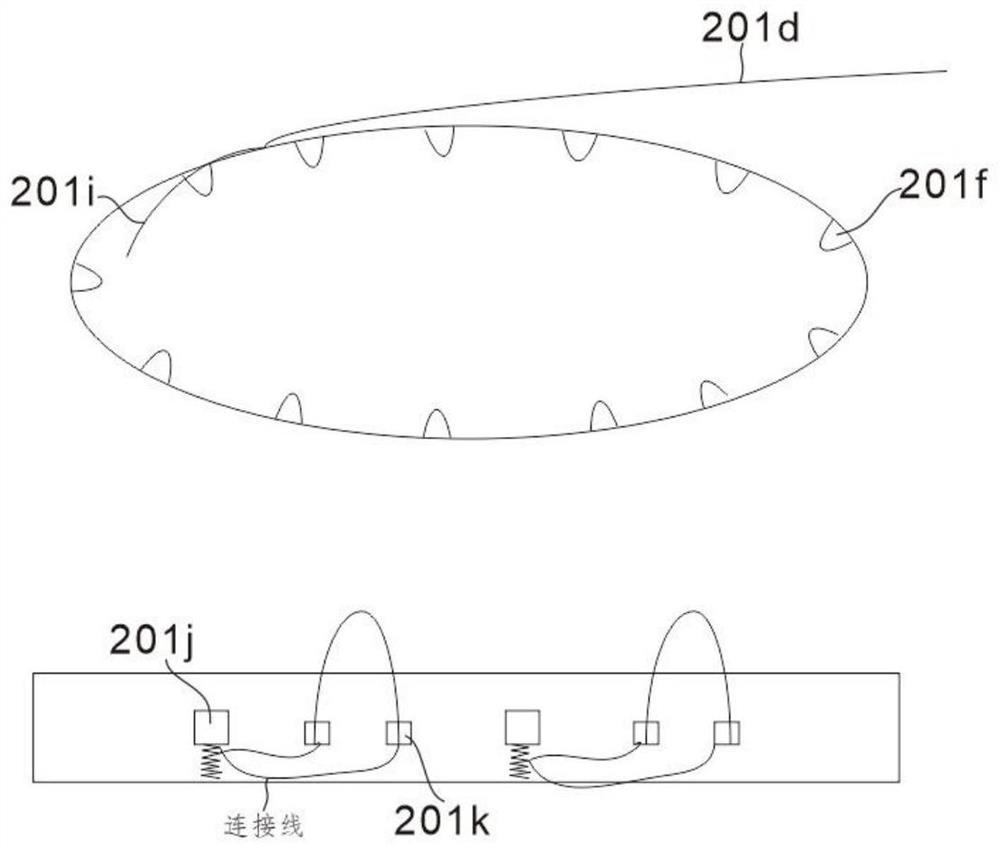

[0034] Preferably, the shell breaking member 201 further includes a shell breaking motor 201c, a belt 201d, and a spring 201e disposed inside the shelling bin 201a. The annular cog 201f is fixedly connected to the spring 201e, and the belt 201d is connected to the bearing of the motor 201c.

[0035] Preferably, the shell breaking member 201 further includes an annular cog 201f disposed inside the shelling channel 201b, an intercepting ring 201g and an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com