Martensite antibacterial stainless steel and preparation method thereof

An antibacterial stainless steel and martensite technology, applied in the field of stainless steel, can solve the problems of reducing material processing performance and corrosion resistance, not showing antibacterial performance, and not mentioning the rapid sterilization and antibacterial performance of materials, so as to achieve rapid sterilization and sterilization. The effect of excellent antibacterial performance and strong bactericidal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

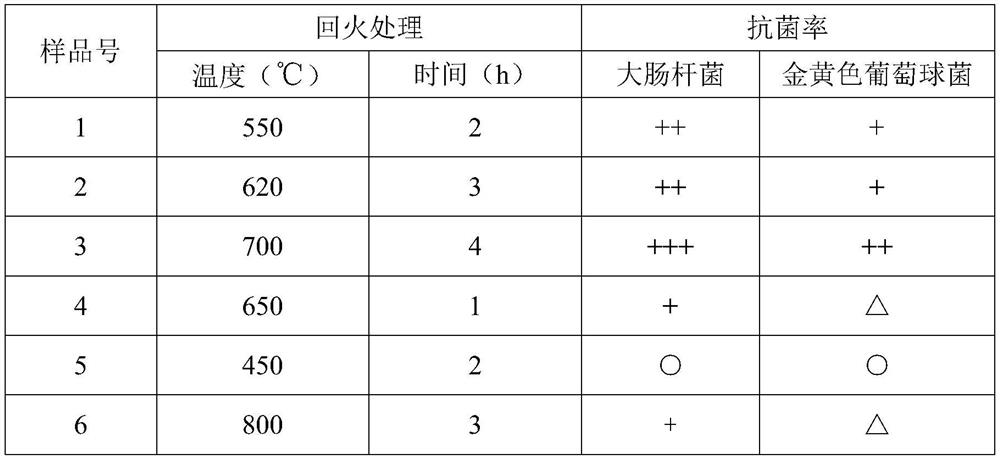

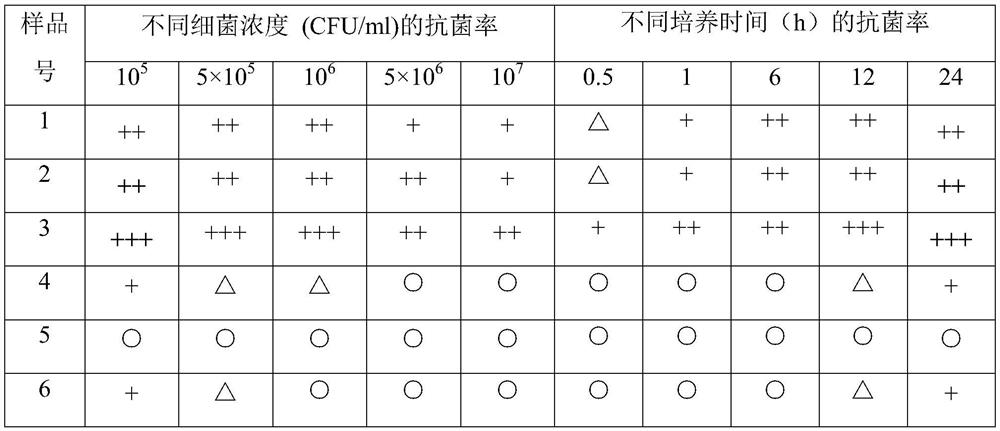

[0023] In this embodiment, the components and weight percentages of martensitic antibacterial stainless steel are: C: 0.45, Si: 0.8, Mn: 0.7, S: 0.03, P: 0.03, Cr: 14.2, Mo: 0.8, V: 0.2, Cu: 2.2, Sc: 0.1, and the balance is Fe. After smelting, forging, hot forging and hot rolling into 5mm thick hot rolled sheet. Among them, the hot forging temperature is 1000°C, the holding time is 2h, and the final forging temperature is 860°C; the hot rolling temperature is 1000°C, the holding time is 2h, and the final rolling temperature is 860°C. After that, heat treatment is carried out, specifically, the temperature is kept at 1000°C for 0.5h, and the oil is cooled to room temperature to make the components of each element evenly distributed in the stainless steel to form a supersaturated solid solution, and then tempered at 550-700°C for 2-4h, air-cooled to At room temperature, the Sc-containing intermediate phase, the copper-rich phase and the carbide are dispersed and precipitated in...

Embodiment 2

[0045] In this embodiment, the components and weight percentages of the martensitic antibacterial stainless steel are: C: 0.48, Si: 0.75, Mn: 0.75, S: 0.02, P: 0.03, Cr: 14.8, Mo: 0.7, V: 0.18, Cu: 2.4, Sc: 0.5, and the balance is Fe. After smelting, forging, hot forging and hot rolling into 5mm thick hot rolled sheet. After that, it was kept at 900 °C for 1 h, and the oil was cooled to room temperature, so that elements such as Sc and Cu were evenly distributed in the stainless steel to form a supersaturated solid solution. Phase, copper-rich phase and carbides are dispersed and precipitated in the matrix to prepare stainless steel.

[0046] The technical effect of the present embodiment 2 is illustrated by the following test comparison, and the samples under different tempering treatments in the embodiment are respectively recorded as samples 7, 8, 9, and 10 (for the specific tempering treatment temperature and time, see Table 4 below).

[0047] When the stainless steel co...

Embodiment 3

[0066] In this embodiment, the components and weight percentages of martensitic antibacterial stainless steel are: C: 0.42, Si: 0.72, Mn: 0.75, S: 0.02, P: 0.03, Cr: 15.1, Mo: 0.85, V: 0.22, Cu: 3.1, Sc: 1.0, and the balance is Fe. After smelting, forging, hot forging and hot rolling into 5mm thick hot rolled sheet. After that, it was kept at 980°C for 0.5h, and the oil was cooled to room temperature, so that elements such as Sc and Cu were evenly distributed in the stainless steel to form a supersaturated solid solution, and then tempered at 550-700°C for 2-4h, and air-cooled to room temperature to make the Sc-containing The intermediate phase, copper-rich phase and carbide are dispersed and precipitated in the matrix to prepare stainless steel.

[0067] 3.1 Antibacterial experiment

[0068] In this experiment, ordinary 5Cr15MoV martensitic stainless steel was used as the control material. The specific experiment is the same as that of Example 1. In Example 3, the samples...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com