Paving thickness measuring device

A measuring device and thickness measuring technology, which is applied to measuring devices, roads, buildings, etc., can solve the problems of lack of continuous detection and real-time feedback, inability to meet the detection requirements of the construction process, and low efficiency of detection methods, so as to ensure the accuracy of measurement. , convenient control, and the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

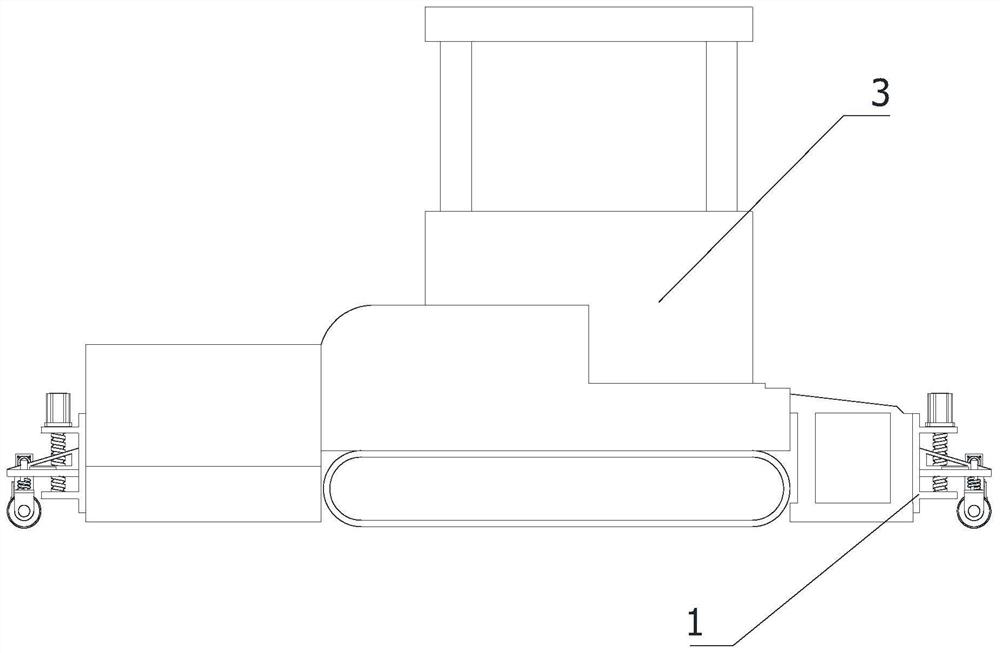

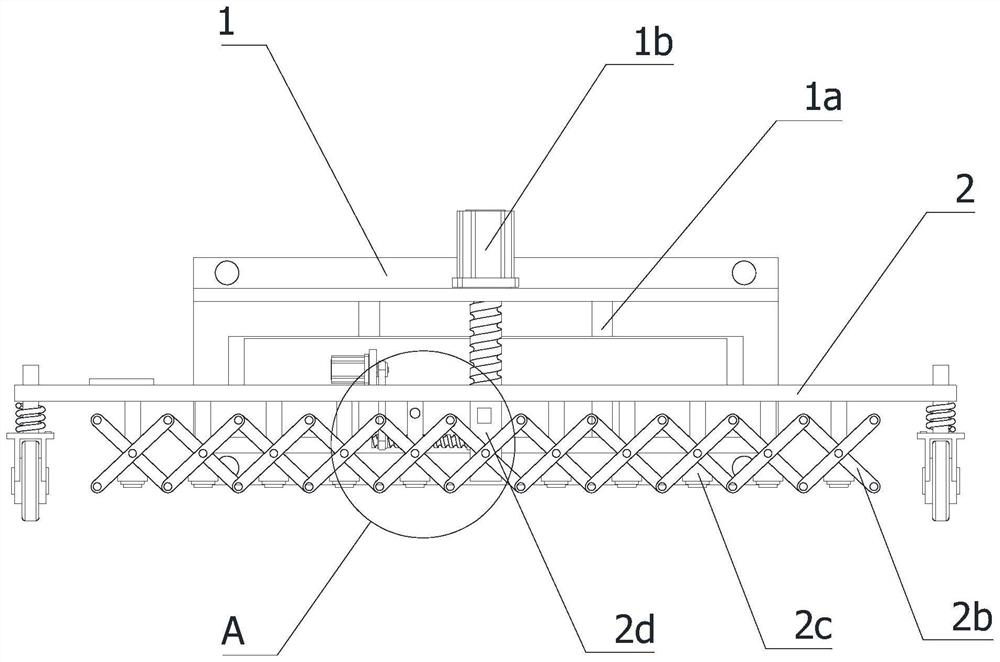

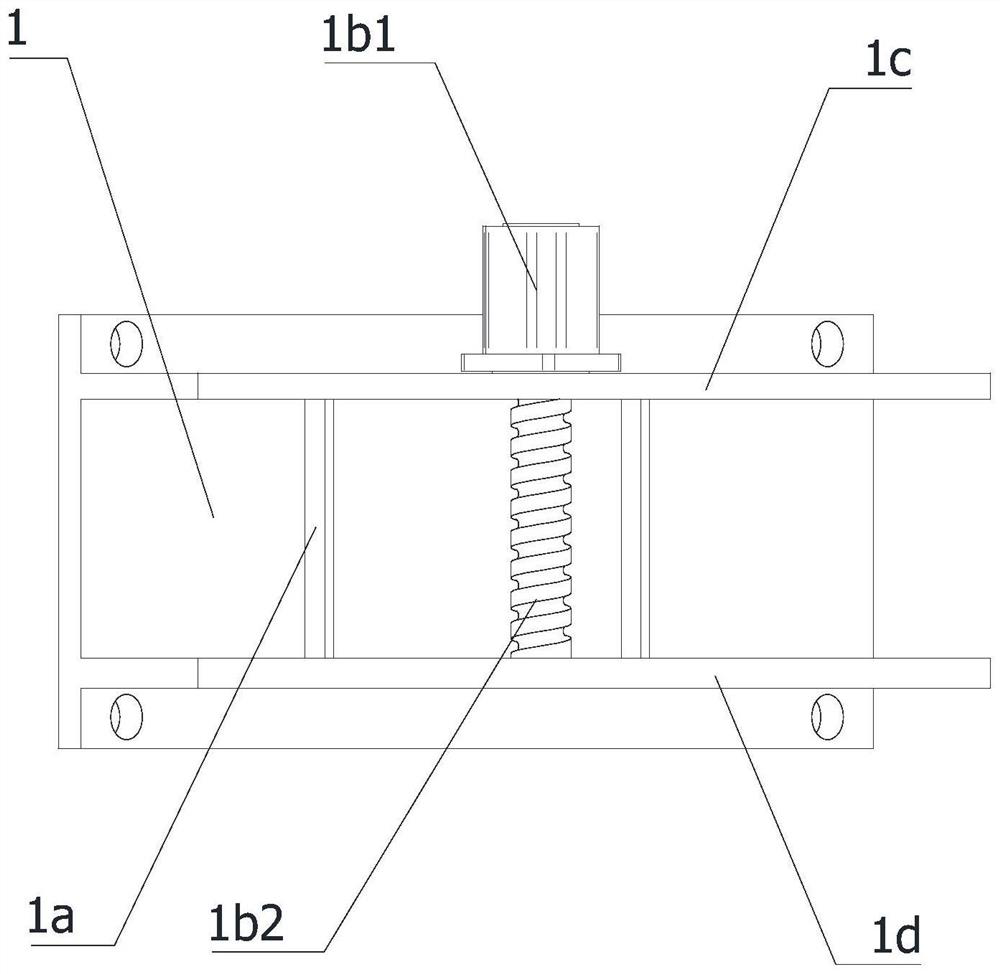

[0039] like Figure 1-10 As shown, this application provides:

[0040]A paving thickness measurement device, comprising two mounting brackets 1, both of which are provided with a first sliding rail 1a, a support arm 2 and a drive for driving the support arm 2 to lift and lower on the mounting bracket 1 Assembly 1b, the first slide rail 1a is arranged along the height direction of the mounting frame 1, the driving assembly 1b is located on the top of the mounting frame 1, the support arm 2 is a rectangular plate-like structure, and the support arm 2 is in a horizontal state slidable on the first slide rail 1a, and the support arm 2 is drivingly connected with the drive assembly 1b. The bottom of the support arm 2 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com