Wheel-rail force wireless monitoring device, system and method

A wireless monitoring device and monitoring system technology, applied in measuring devices, signal transmission systems, force/torque/power measuring instruments, etc., can solve the impact of train driving safety, inaccurate positioning of pasted strain gauges, and inability to obtain real-time data, etc. problems, to achieve the effect of saving manpower and material resources, improving measurement accuracy, and realizing wireless transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

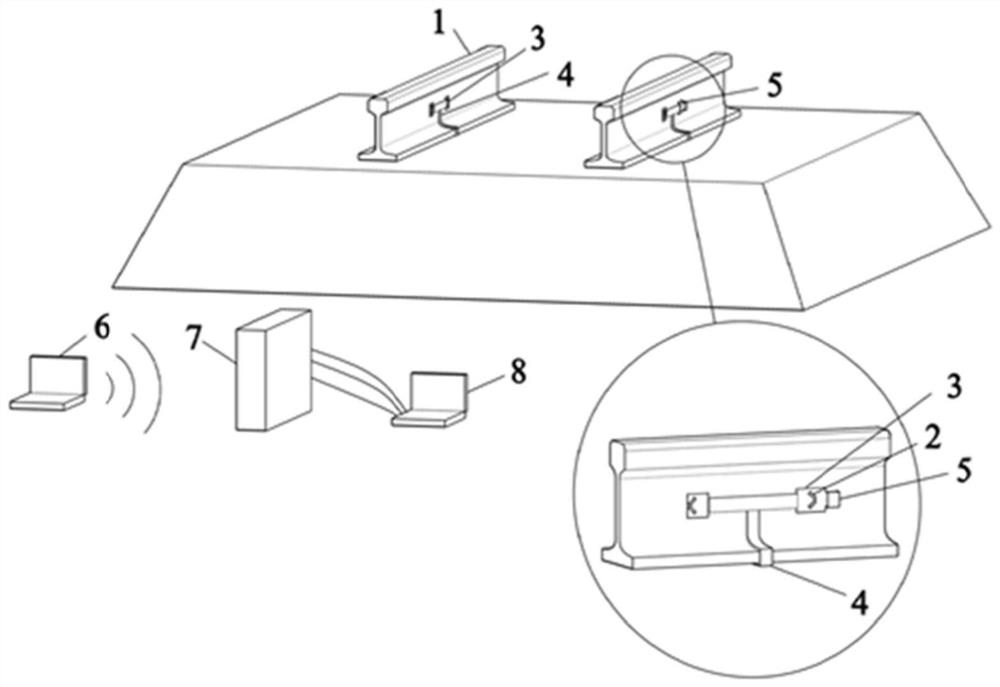

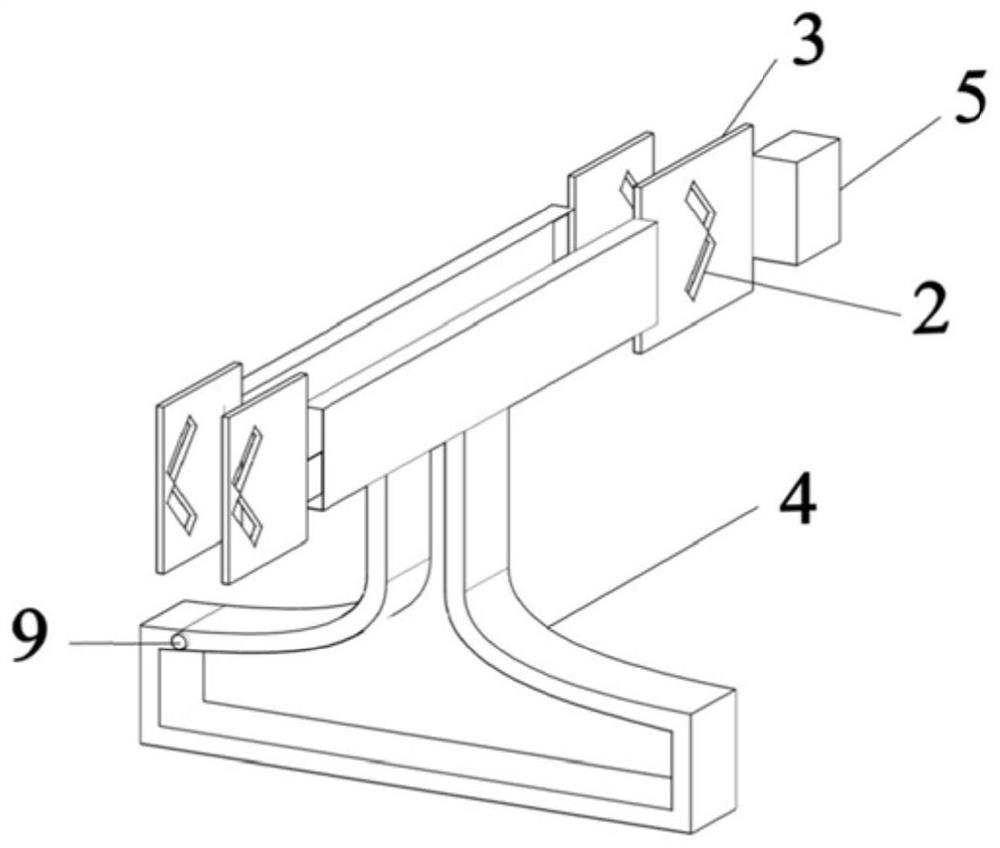

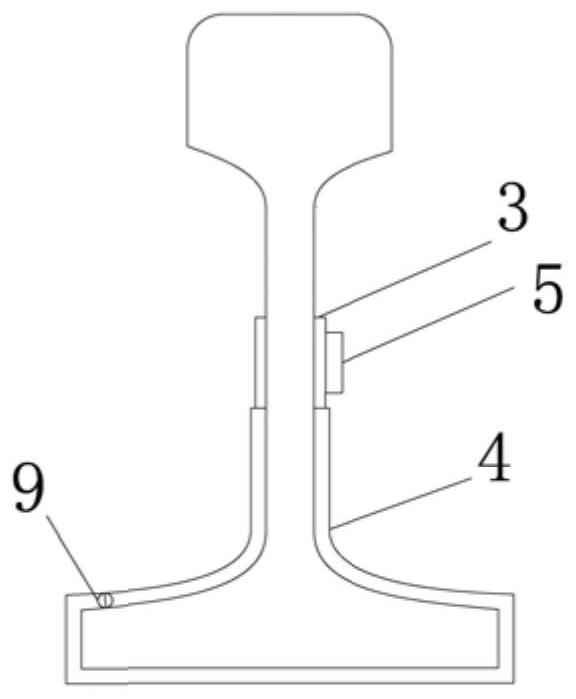

[0034] like figure 1 , figure 2 The shown wireless monitoring device for wheel-rail force includes a data acquisition mechanism and a wireless monitoring mechanism adapted to the data acquisition mechanism. The adapted integrated circuit board 3, the data acquisition card 5 and the biaxial strain gauge 2 arranged on the integrated circuit board 3, the integrated circuit board 3 is provided with a strain gauge positioning hole, and the biaxial strain gauge 2 is arranged on the strain gauge positioning hole. in the hole.

[0035] like image 3 As shown, the junction box 4 is a combined junction box, and a buckle 9 is provided on the combined junction box. The junction box 4 is adapted to the lower half of the steel rail 1, and the material of the junction box 4 is hard plastic.

[0036] like Figure 4 As shown, there are four integrated circuit boards 3 in total, two of which are matched with the inner side of the steel rail 1 , and the other two IC boards 3 are matched wi...

Embodiment 2

[0040] A wheel-rail force wireless monitoring system, based on the wheel-rail force wireless monitoring device in Embodiment 1, the system includes a plurality of data collection mechanisms for collecting wheel-rail force data at different positions of the rail 1, and a plurality of data collection mechanisms. A wireless monitoring mechanism that is compatible with the mechanism.

Embodiment 3

[0042]A method for wireless monitoring of wheel-rail force, based on the wheel-rail force wireless monitoring system in Embodiment 2, such as Figure 7 As shown, the method is as follows: install multiple data acquisition mechanisms at different monitoring positions of the rail 1 to collect the wheel-rail force data at each position of the rail 1, and realize the wireless monitoring of the wheel-rail force through the wireless monitoring mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com