Reflection-type afocal optical system

An afocal optical system and reflective technology, applied in the optical field, can solve the problems of large volume, large beam incident angle, and high difficulty of plane mirror image stabilization components, and achieve the effect of reducing light loss and reducing the size of the central hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

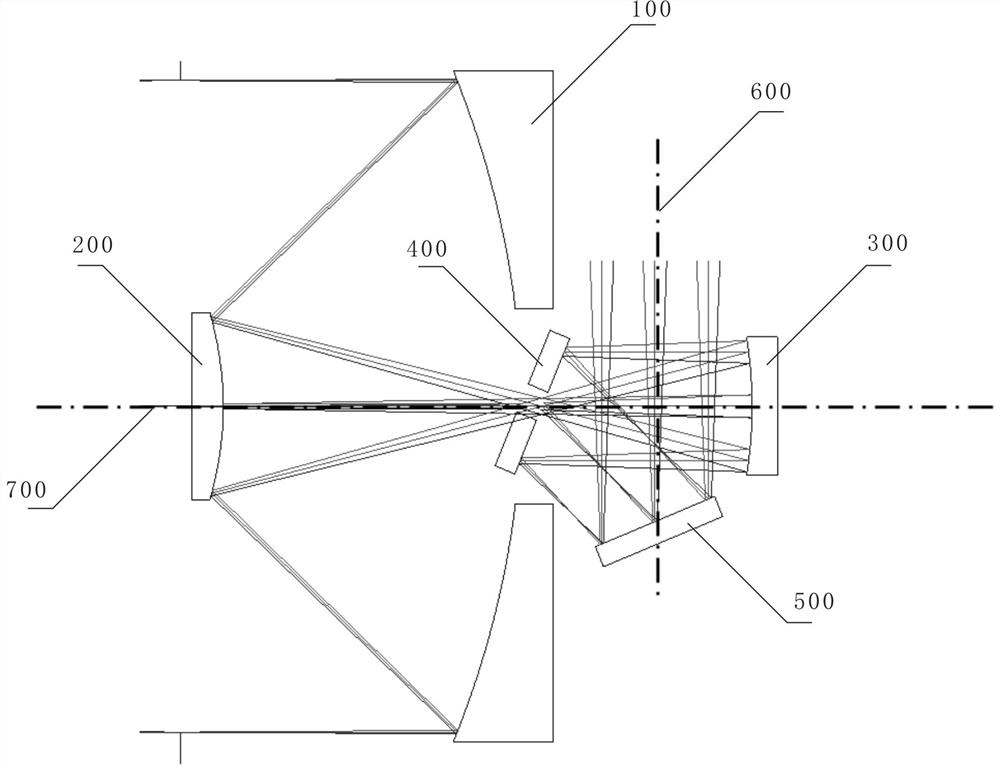

[0029] like figure 1 As shown, a reflective afocal optical system includes a primary mirror 100, a secondary mirror 200, a third mirror 300, a plane mirror A400 and a plane mirror B500, wherein the optical power of the primary mirror 100, the secondary mirror 200 and the third mirror 300 is not Zero and arranged with the optical axis, forming a common optical axis A700;

[0030] There is a through hole in the middle of the primary mirror;

[0031] The secondary mirror 200 is located on the reflection side of the primary mirror 100, receives the light beam reflected by the primary mirror 100, collects the light beam reflected by the primary mirror 100, and reflects it from the through hole;

[0032] The three mirrors are located on the reflection side of the secondary mirror and behind the primary mirror, and receive the light beam reflected by the secondary mirror;

[0033] The plane mirror A400 receives the light beam reflected by the three mirrors, and is located between t...

Embodiment 2

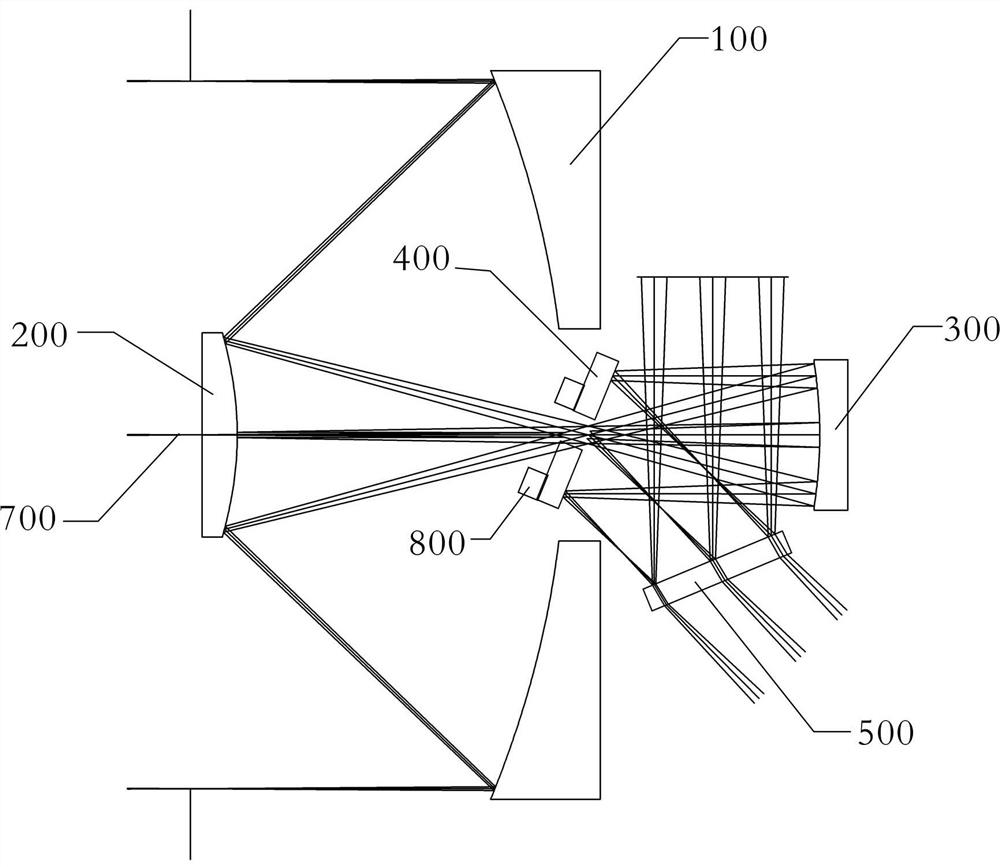

[0045] like figure 2 As shown, a reflective afocal optical system includes a primary mirror 100, a secondary mirror 200, a third mirror 300, a plane mirror A400 and a plane mirror B500, wherein the optical power of the primary mirror 100, the secondary mirror 200 and the third mirror 300 is not Zero and arranged with the optical axis, forming a common optical axis A700;

[0046] There is a through hole in the middle of the primary mirror;

[0047] The secondary mirror 200 is located on the reflection side of the primary mirror 100, receives the light beam reflected by the primary mirror 100, collects the light beam reflected by the primary mirror 100, and reflects it from the through hole;

[0048] The three mirrors are located on the reflection side of the secondary mirror and behind the primary mirror, and receive the light beam reflected by the secondary mirror;

[0049] The plane mirror A400 receives the light beam reflected by the three mirrors, and is located between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com