Intelligent sensing inspection system and method for transformer substation

An inspection system and intelligent perception technology, applied in the field of intelligent perception inspection system, can solve the problems of laborious inspection, weak robustness of detection and recognition algorithm, lack of inspection personnel, etc., achieve high reliability and reduce human intervention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

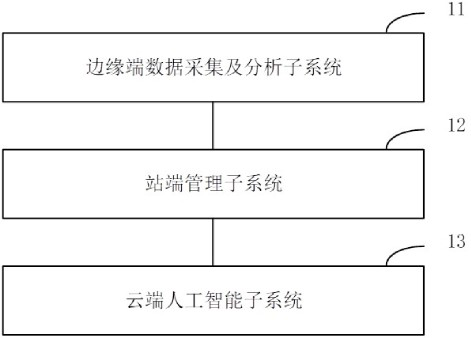

[0032] figure 1A result block diagram of an intelligent perception inspection system for a substation is provided for the first embodiment of the present invention. figure 2 It is a structural block diagram of another intelligent sensing inspection system for a substation provided according to the first embodiment of the present invention. like figure 1 and figure 2 As shown, the system includes: an edge-side data collection and analysis subsystem 11, a station-side management subsystem 12, and a cloud artificial intelligence subsystem 13, wherein the edge-side data collection and analysis subsystem 11, and the station-side management subsystem 12 The communication connection is used to receive the inspection tasks issued by the station-side management subsystem 12. Based on the inspection tasks, the target inspection data of the target inspection objects in the substation are collected, and the target inspection data corresponding to the target inspection data are collect...

Embodiment 2

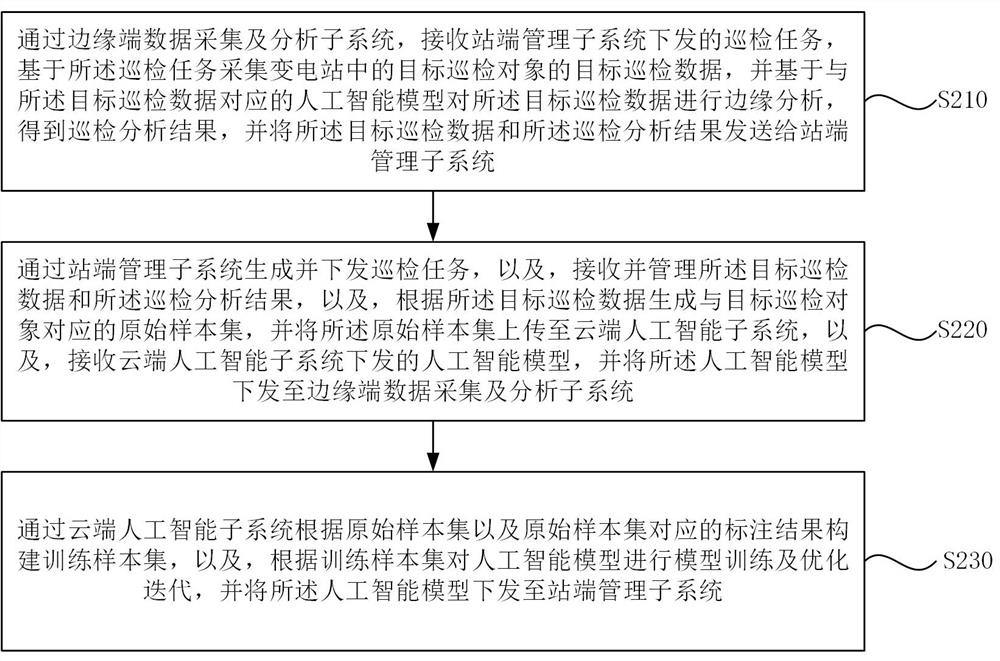

[0097] image 3 An intelligent sensing inspection method for substations provided in Embodiment 2 of the present invention is characterized in that it is applied to an intelligent sensing inspection system for substations, and the intelligent sensing inspection for substations includes edge data. A collection and analysis subsystem, a station-side management subsystem and a cloud artificial intelligence subsystem, the station-side management subsystem is respectively connected in communication with the edge-side data collection and analysis subsystem and the cloud artificial intelligence subsystem. like image 3 As shown, the intelligent sensing inspection method for substations includes:

[0098] S210. Receive the inspection task issued by the station-side management subsystem through the edge-side data collection and analysis subsystem, collect target inspection data of the target inspection object in the substation based on the inspection task, and collect the target inspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com