Spraying rotary clamp for spraying and winding thermal insulation pipe and clamping method

A technology of rotating fixtures and heat preservation pipes, applied in the direction of spraying devices, etc., can solve the problems of eccentricity and asynchronous expansion between the steel pipe to be sprayed and the rotating trolley, and achieve the goals of reducing socket fitting time, improving efficiency, and improving spraying quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

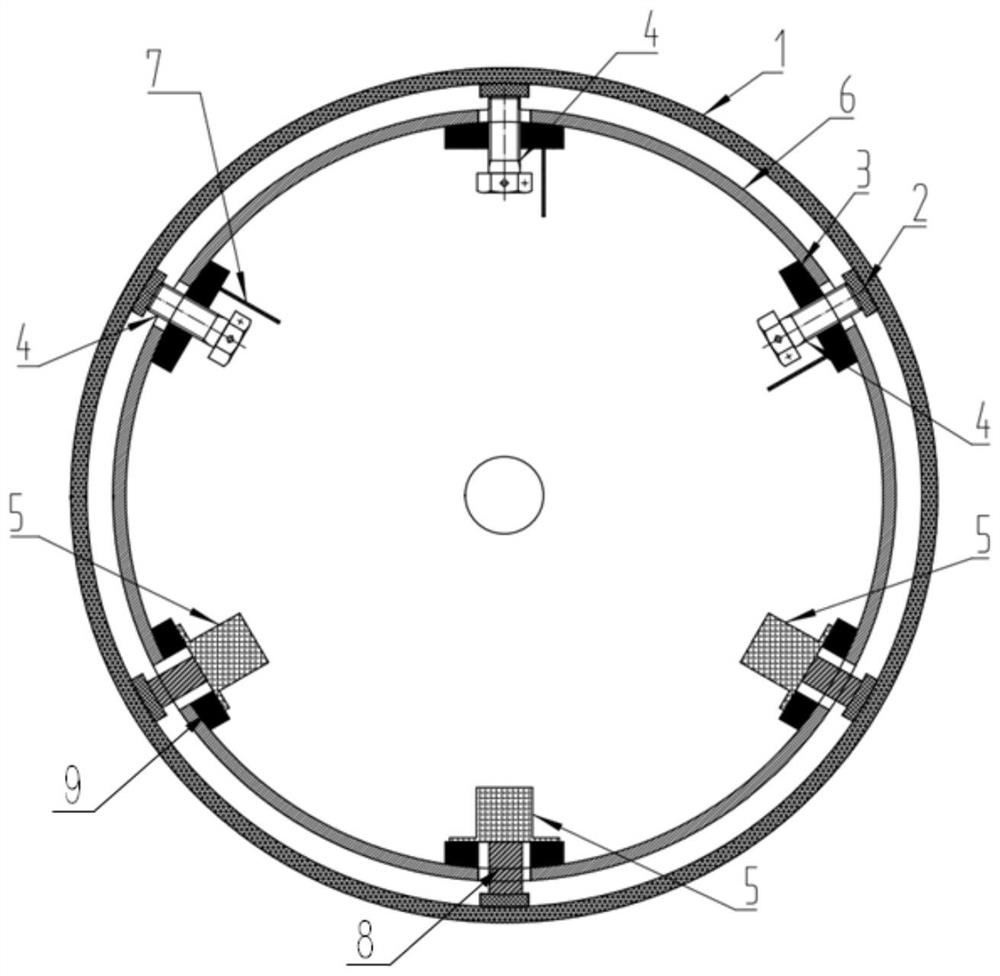

[0028] like figure 1 As shown, the present embodiment provides a spraying rotating fixture for spraying, winding and insulating pipes, including a socket sleeve 6 with an outer diameter smaller than the steel pipe 1 to be sprayed, one end of which is used to connect with the rotating shaft of the rotating trolley, and the other end is along the circumference of the The direction is provided with at least two continuously arranged positioning rods 4 and at least two continuously arranged jacking rods 8, and the axial directions of the positioning rods 4 and the jacking rods 8 are pushed along the radial direction of the socket sleeve 6;

[0029] Wherein, the arc chord length formed by any two positioning rods 4 along the circumference is smaller than the diameter of the circumference, and the arc formed by pushing the top of the positioning rod 4 is overlapped with the inner wall of the steel pipe 1 to be sprayed for positioning. The rod 8 and the positioning rod 4 jointly supp...

Embodiment 2

[0044] According to the difference between the inner diameter of the steel pipe 1 to be sprayed and the outer diameter of the socket sleeve 6, the height of the push of the positioning rod 4 is determined, usually the height after the positioning rod 4 is pushed (the distance between the top of the positioning rod 4 and the outer wall of the socket sleeve 6 ) is equal to the difference between the inner diameter of the steel pipe 1 to be sprayed and the outer diameter of the socket sleeve 6, or slightly larger, leaving a certain amount of compensation to compensate for the gap between the threads.

[0045] After the pushing of the positioning rod 4 is completed, the arc formed by the connection at the top can be overlapped with the inner wall of the steel pipe 1 to be sprayed. On the cylinder 6, the top of the positioning rod 4 is in contact with the inner wall of the steel pipe 1 to be sprayed, so that the concentric positioning with the socket sleeve 6 can be realized, the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com