Rotary ejection mechanism of injection mold

A rotary ejection and injection mold technology, applied in the field of injection molds, can solve the problems of cumbersome and unstable movement process, undercuts sticking to the ejector mechanism, low product yield, etc., to achieve a streamlined and stable movement process and ensure stable demoulding , The effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

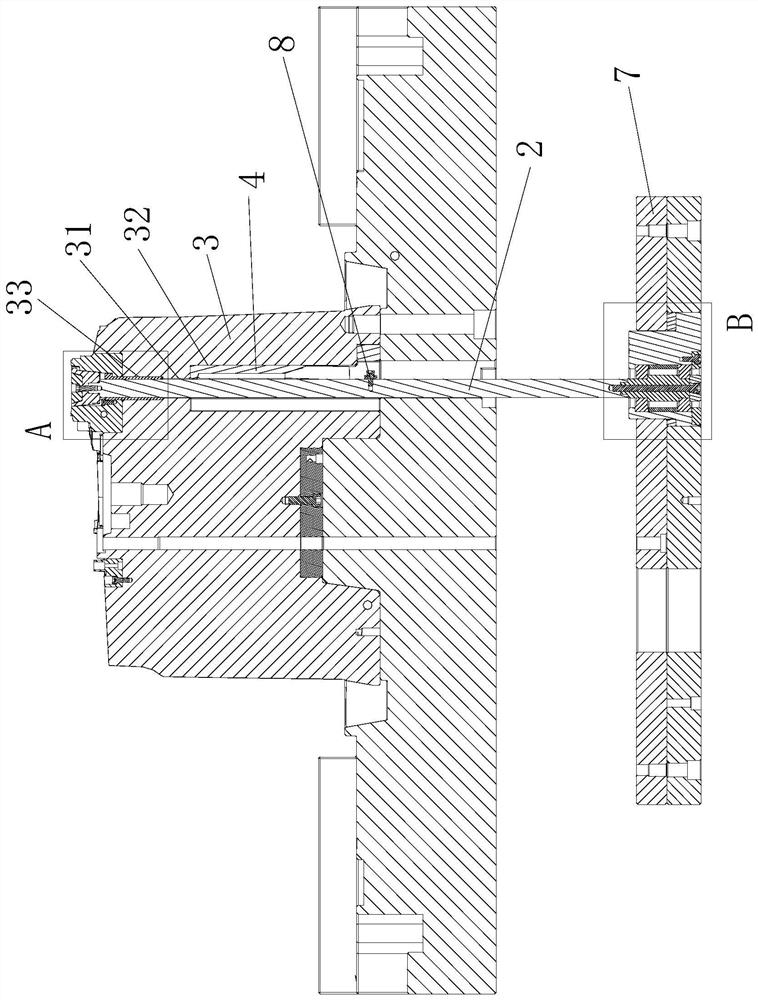

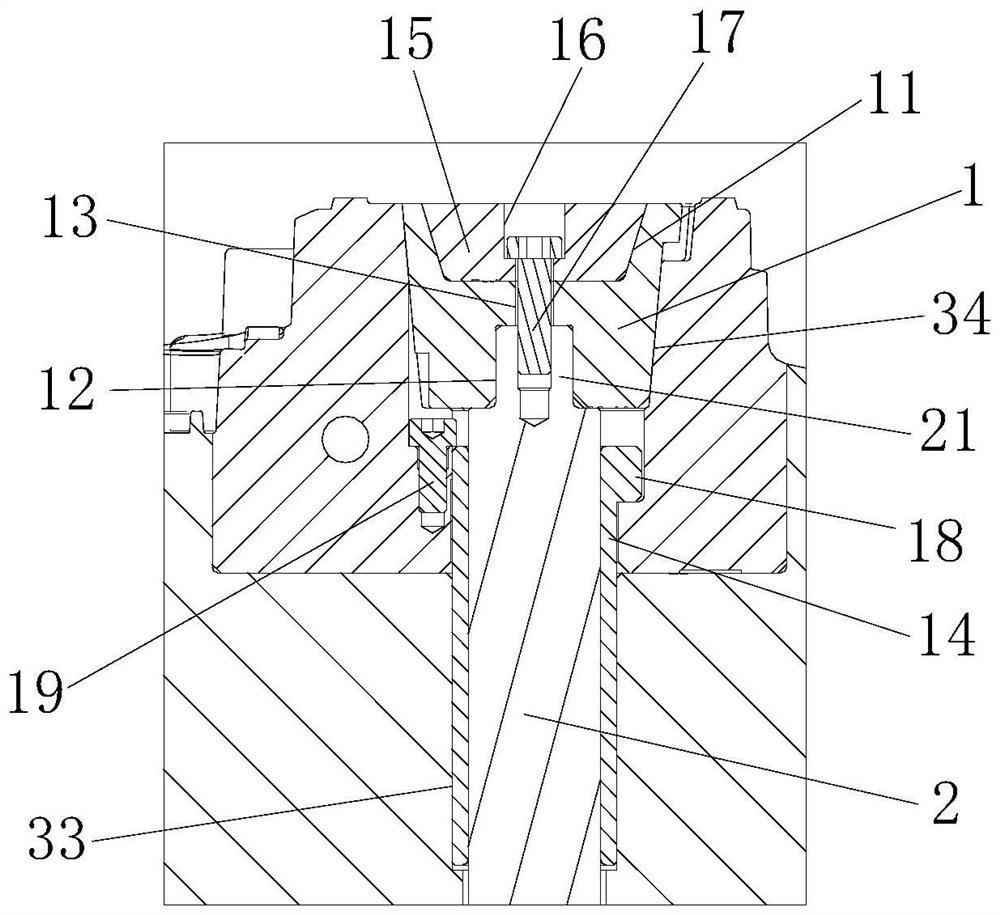

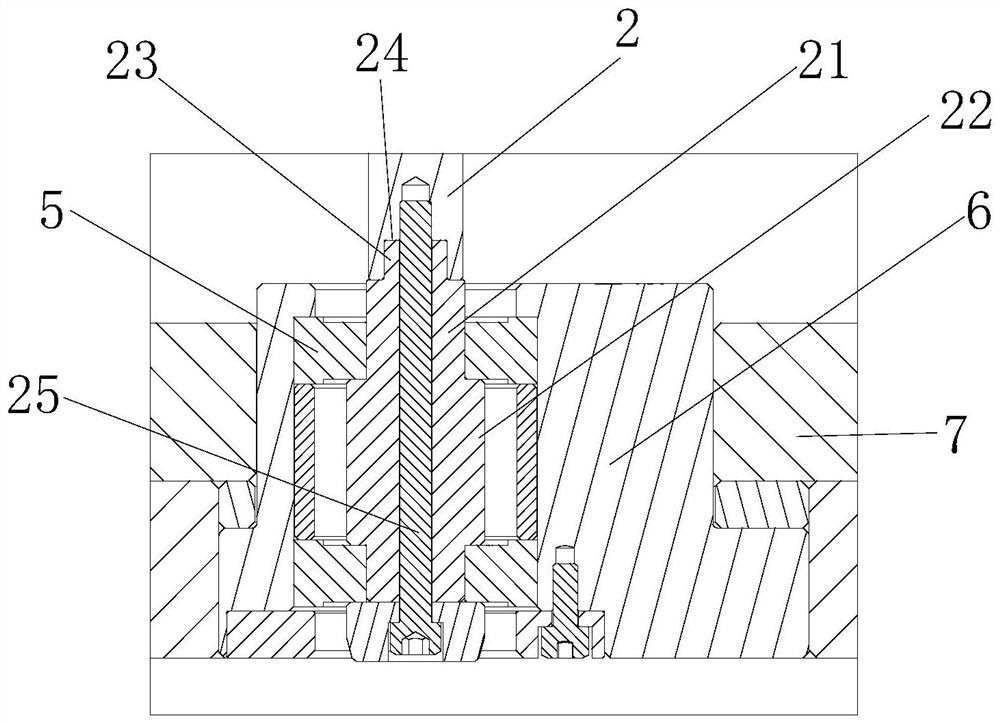

[0021] The present invention will be further described below with reference to the accompanying drawings and specific embodiments. like Figure 1-4 As shown, the rotary ejection mechanism of the injection mold includes a movable mold, and the movable mold includes a movable mold insert 3 , an ejector plate 7 , a rotary core-pulling block and a guide block 4 . The rotary core-pulling block includes a rotary head 1 and a connecting rod 2 that are connected to each other. A rotary core-pulling groove 34 is made in the movable die insert 3. The rotary head 1 is located in the rotary core-pulling groove 34. Snap-molded molding bumps 10 . When the mold is closed, the rotary head 1 and the movable mold insert 3 together form part of the mold cavity. An ejection hole 31 is formed in the movable mold, the rotary core pulling groove 34 communicates with the ejection hole 31 , and the connecting rod 2 is located in the ejection hole 31 . The bottom of the connecting rod 2 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com