Rib type composite material component and preparation method thereof

A composite material component, rib-shaped technology, applied in household components, other household appliances, household appliances, etc., can solve the problems of poor matching of positive film support blocks, inability to fit closely, etc., to achieve high fit and improve pressure transmission. Sex, high success rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of ribbed composite members

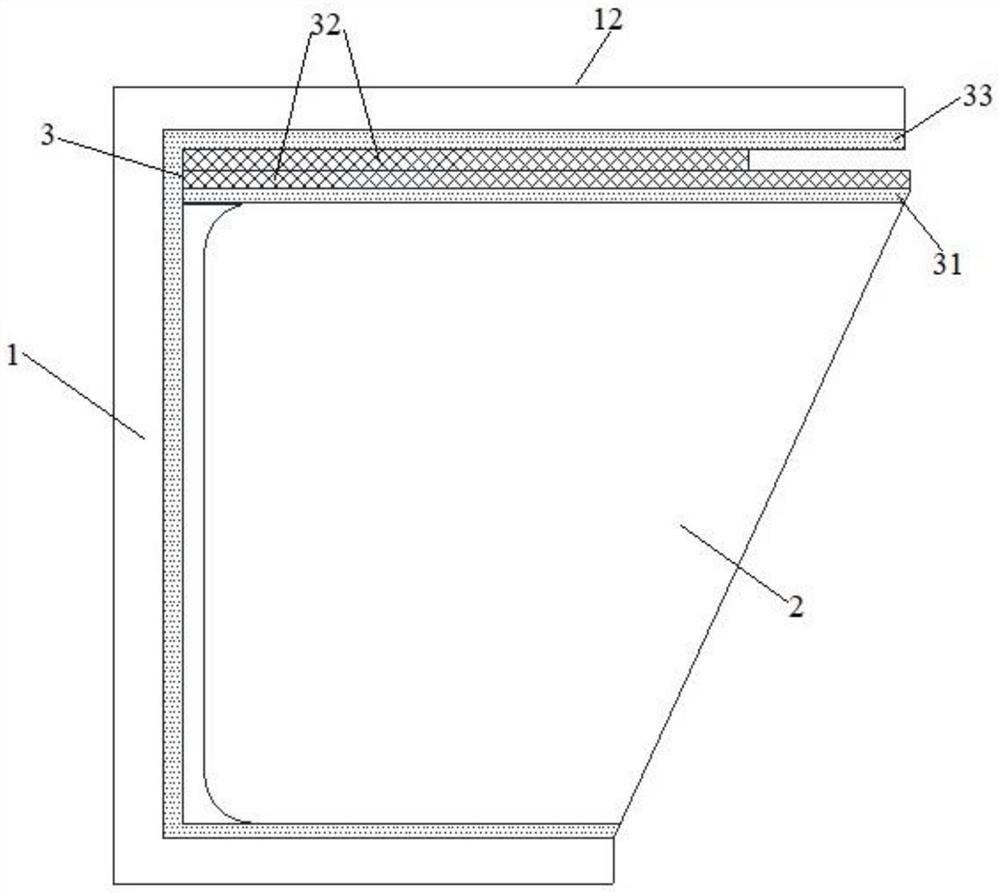

[0039] First, a first layer of adhesive release cloth 31 is fully spread on the top surface 21 of the positive film support block 2 .

[0040]Then, a layer of EW100A prepreg material is fully laid on the first adhesive release cloth 31, then a layer of EW100A prepreg material is laid on top of the EW100 prepreg material, and a second layer of EW100A prepreg material is laid The material layer is not fully laid, but the end near the opening area is 20mm shorter than the EW100 prepreg material layer at the bottom. Two layers of EW100 prepreg make up the flexible material layer 32 . The flexible material layer 32 may also be a ZTTH prepreg material or an EW290 prepreg material. The fluidity of the flexible material layer 32 is 15 mm. The thickness of the flexible material layer 32 is 0.15 mm larger than the maximum gap value between the top surface 21 of the male film support block 2 and the supported surface 111 .

[0041] N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com