Blade overall flexible deformation method based on mean camber line

A blade and arc technology, applied in the field of geometric modeling of aero-engine blades, can solve the problems of inability to fully describe the deformation of the blade, unable to adapt to the local adjustment of the blade model, etc., and achieve the effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

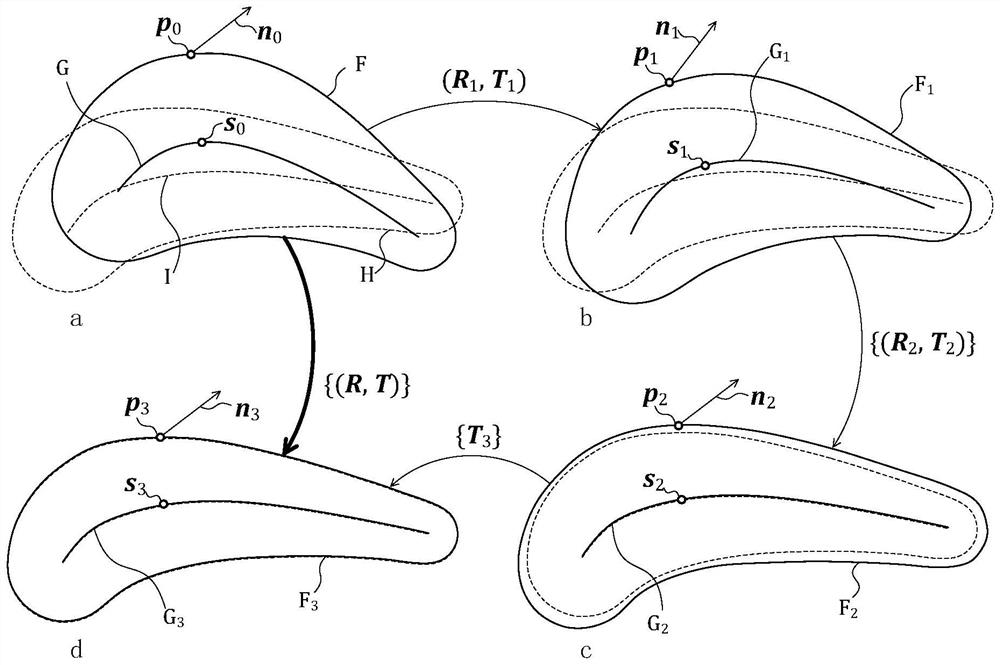

[0055] The present invention will be further described below with reference to the accompanying drawings and embodiments. The embodiments are exemplary and are intended to be used to explain the present invention, but should not be construed as a limitation of the present invention.

[0056] In the embodiment of the present invention, the measured blade and the designed blade are in the same coordinate system, and the corresponding relationship between the measured blade section line and the designed blade section line and the section position are provided externally. Specifically, a method for flexible deformation of a blade as a whole based on a mid-arc line of the present invention includes the following steps:

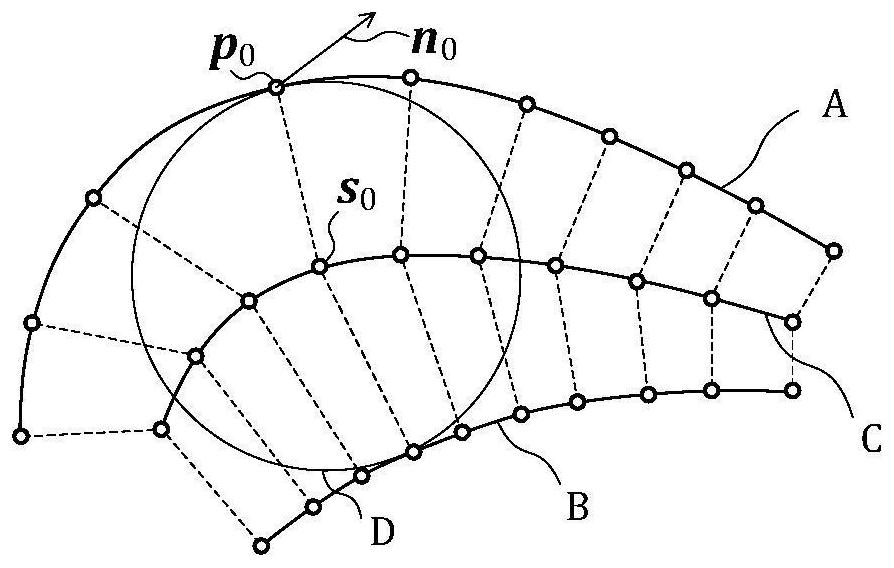

[0057] Step 1. Obtain the discrete points of the design blade

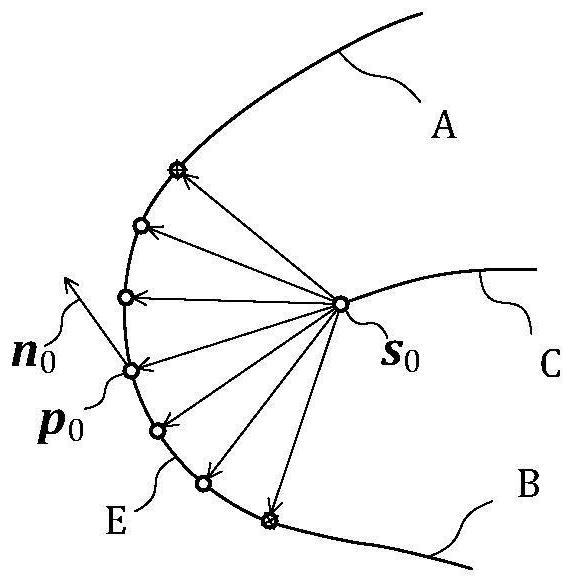

[0058] Obtain any set of section lines corresponding to the designed blade and the measured blade, and extract the mid-arc line of the designed blade section line, discretize the mid-arc line of the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com