Non-excitation switch wiring structure and transformer

An excitation switch and transformer technology, applied in the field of transformers, can solve the problems of non-conduction of tap lines, unreliable connection, large ratio error, etc., and achieve the effects of prolonging life, reliable connection and reducing ratio error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

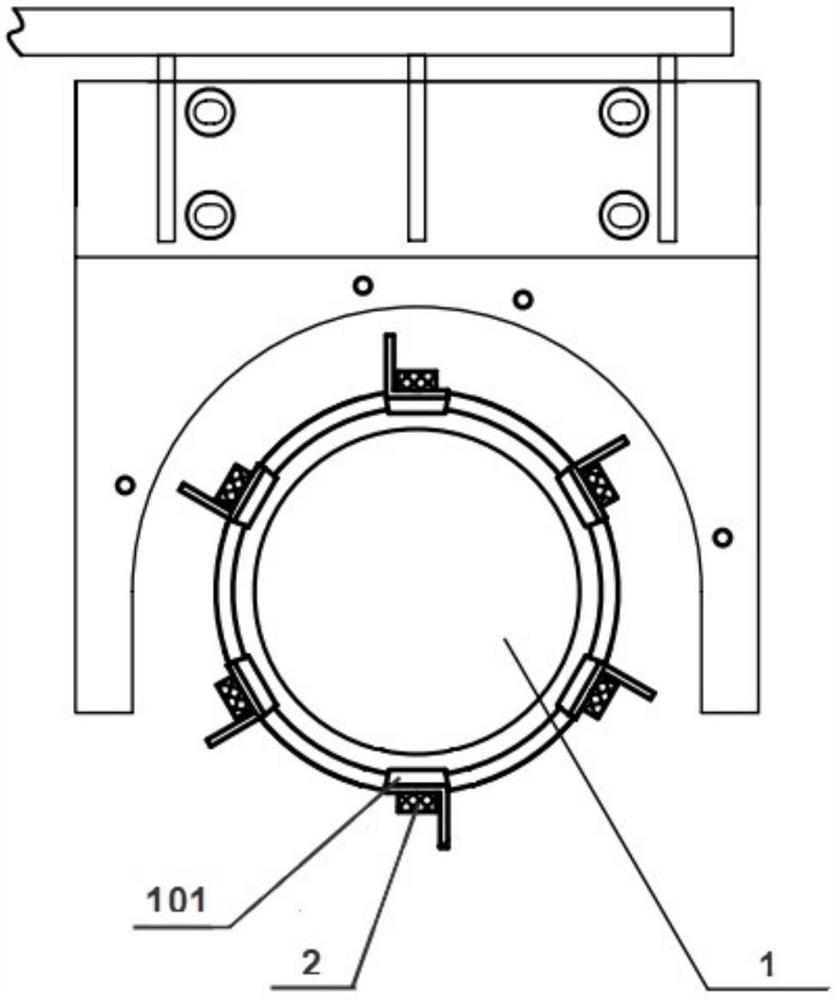

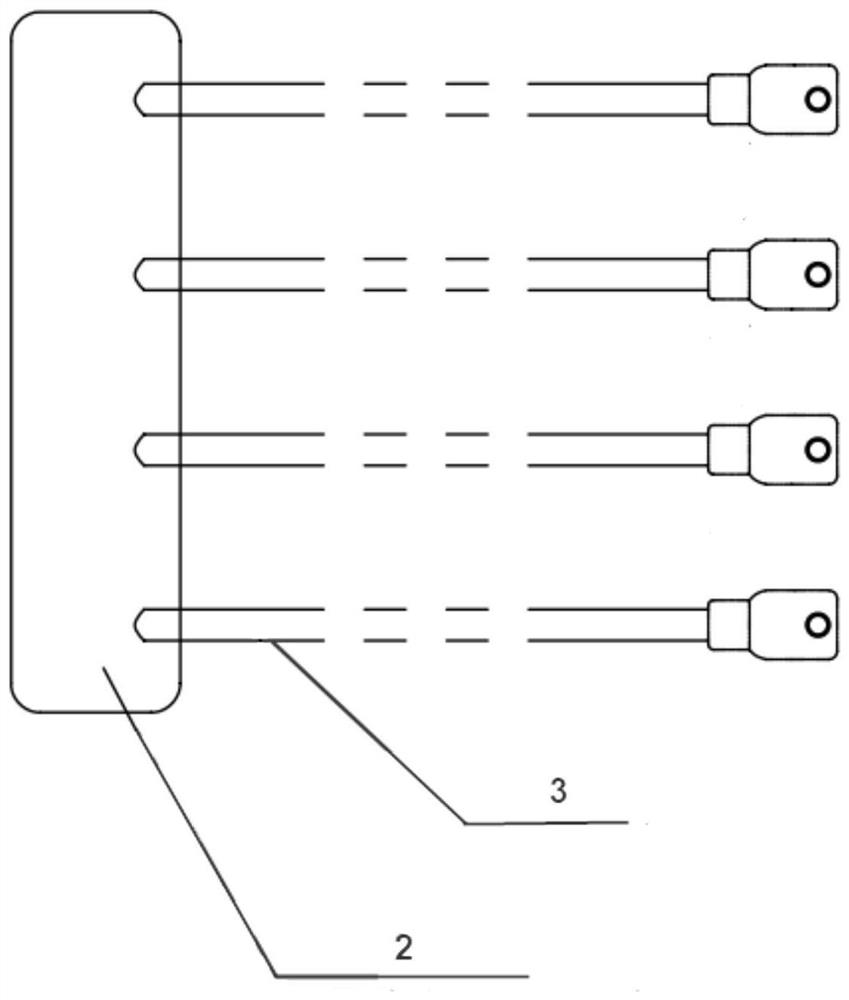

[0031] The embodiment of the present invention provides a non-excitation switch connection structure, figure 1 It is a schematic diagram of the connection structure of the non-excitation switch provided by the embodiment of the present invention. like figure 1 shown, the non-excitation switch wiring structure includes such as figure 1 The non-excited switch 1, short-circuit copper bar 2 and transition lead 3 are shown. The non-excited switch 1 includes a fixed contact 101 ; the short-circuit copper bar 2 includes a first surface and a second surface, and the first surface and the second surface are opposite surfaces. The fixed contact 101 is connected to the first surface of the shorting copper bar 2 , and the transition lead 3 is connected to the second surface of the shorting copper bar 2 .

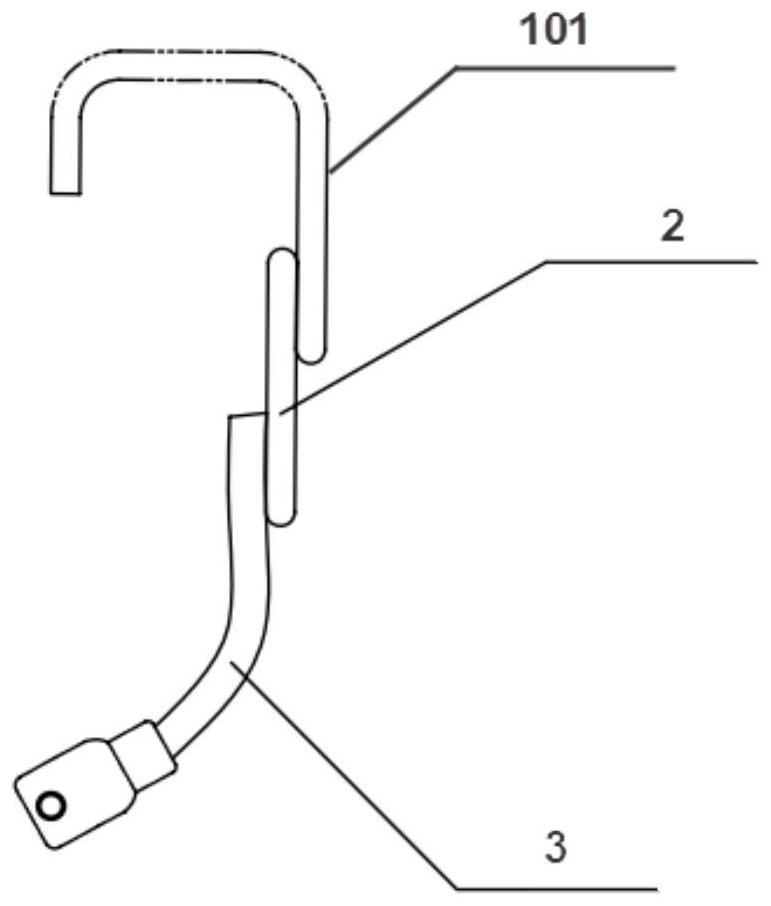

[0032] like figure 2 As shown, the fixed contact 101 is a J-shaped structure, including a long side, a short side and a curved portion, the long side is connected with the short si...

Embodiment 2

[0039] Based on the foregoing embodiments, the non-excitation switch connection structure proposed in this embodiment takes into account the requirements of the number of transformer connections and reliability, and can be better applied to transformer application scenarios. The non-excitation switch connection structure proposed in this embodiment includes a non-excitation switch 1 , a short-circuit copper bar 2 and a transition lead 3 . The non-excited switch 1 includes a fixed contact 101 ; the short-circuit copper bar 2 includes a first surface and a second surface, and the first surface and the second surface are opposite surfaces. The fixed contact 101 is connected to the first surface of the shorting copper bar 2 , and the transition lead 3 is connected to the second surface of the shorting copper bar 2 . The fixed contact 101 is a J-shaped structure, including a long side, a short side and a curved portion, the long side is connected to the short side through the curve...

Embodiment 3

[0042] Based on the foregoing embodiments, the present invention further provides a transformer, wherein the transformer includes the non-excitation switch wiring structure described in any one of the foregoing embodiments 1-2. Please note that the technical features of the above embodiments can be combined arbitrarily. In order to simplify the description, all possible combinations of the technical features in the above embodiments are not described. However, as long as there is no contradiction in the combination of these technical features , should be considered to be within the scope of this specification. The above examples only represent several embodiments of the present invention, and the descriptions thereof are specific and detailed, but should not be construed as a limitation on the scope of the invention patent. It should be pointed out that for those skilled in the art, without departing from the concept of the present invention, several modifications and improvemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com