Frying and baking type multifunctional food processor

A multi-functional food and processing machine technology, applied in frying pans, special containers for baking, roasters/barbecue grids, etc. It solves the problems of fried food, etc., and achieves the effect of saving cooking time, saving storage space and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

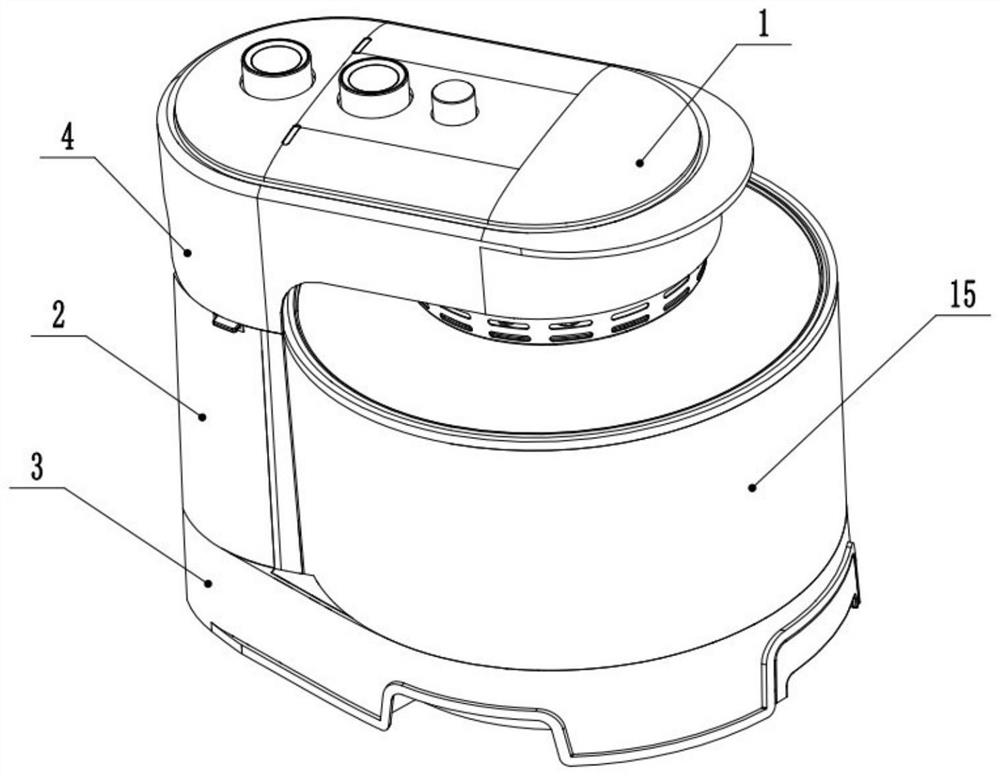

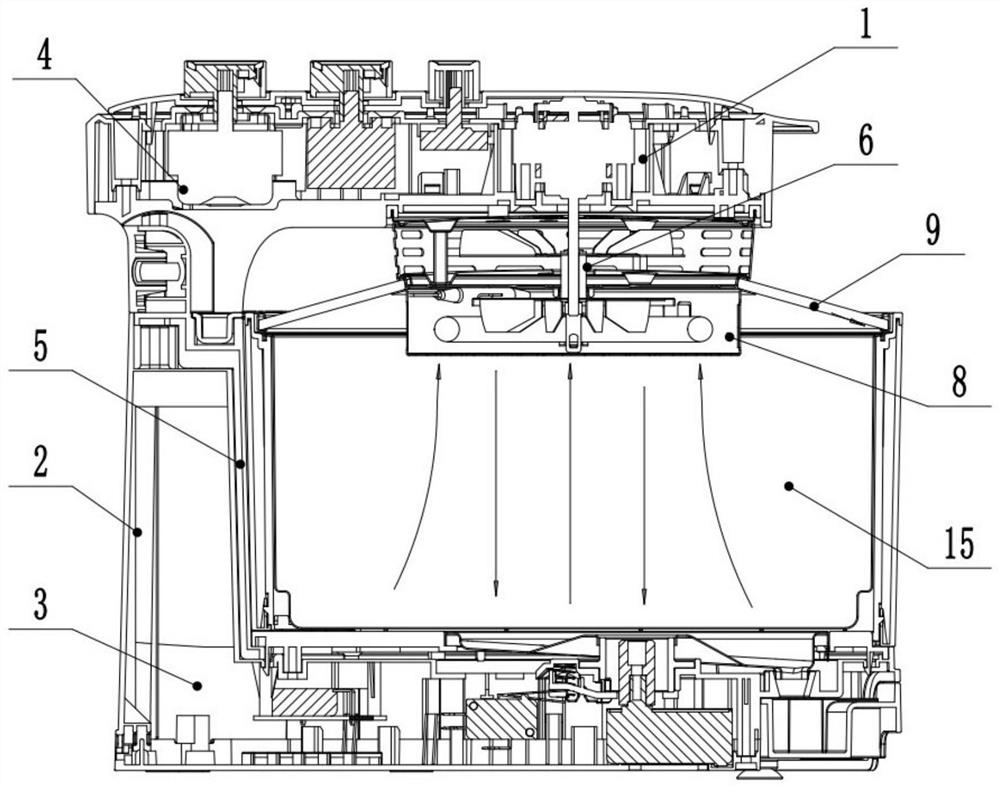

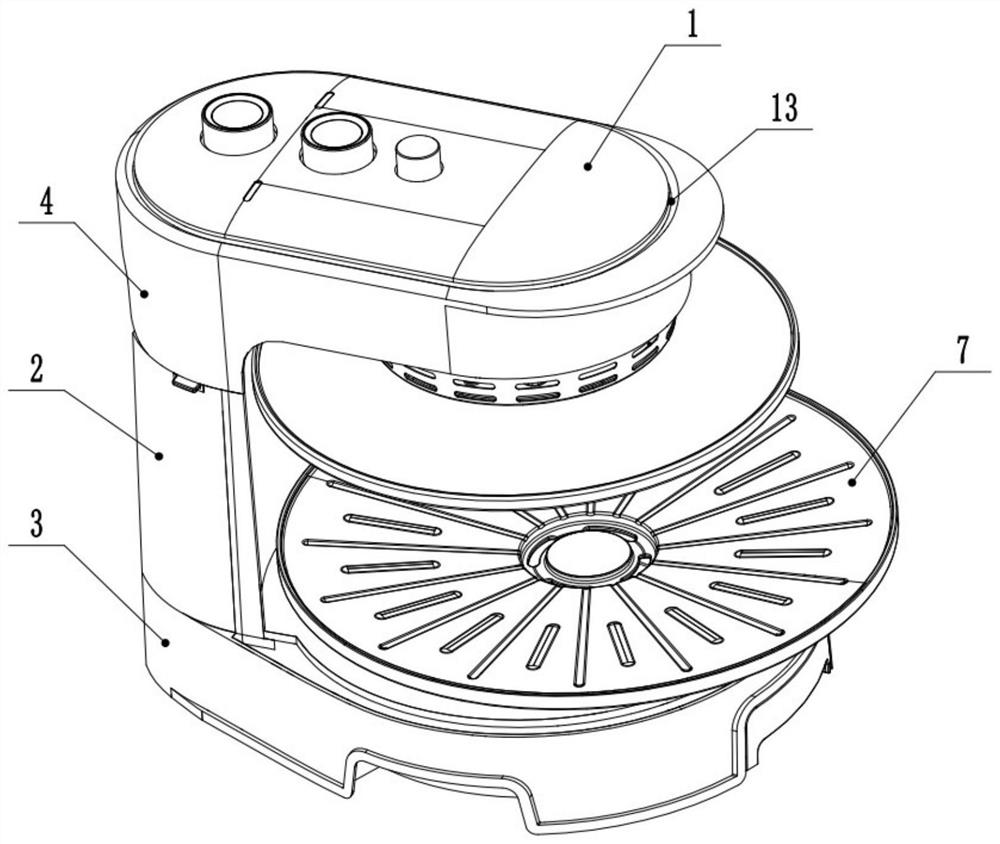

[0044] like Figure 1 to Figure 5As shown, a frying-type multifunctional food processor includes a head 1, a body 2 and a base 3, the body 2 is arranged on one side of the base 3, and the head 1 includes a casing, a hot air device 6 , a reflector and a protective cover 8, the hot air device 6 includes a motor 6-1, a hot fan 6-4 and a heating device 6-5, the motor 6-1 is located between the housing and the reflector, the hot fan 6-1 -4 and a heating device 6-5 are arranged between the reflector and the protective cover 8, the output shaft of the motor 6-1 is connected to the heat fan 6-4 through the reflector, and the heating device 6-5 surrounds the heat fan 6-4 Setting, the base 3 is provided with detachable frying utensils, the handpiece 1 is fixed on the fuselage 2 through the connecting arm 4, the handpiece 1 is provided with a heat collecting cover 9, the The heat collecting cover 9 is arranged around the protective cover 8, and the bottom wall of the protective cover 8 ...

Embodiment 2

[0074] like Image 6 As shown, the difference from the first embodiment is the structure of the reflector and the installation position of the heat collecting cover 9, and the rest of the contents are the same as those of the first embodiment.

[0075] The upper reflector 11 , the heat dissipation ring 16 and the lower reflector 12 are of an integrated structure.

[0076] A limit step is provided above the protective cover 8, and the lower reflector 12 presses the heat collecting cover 9 on the limit step.

[0077] To sum up, the upper and lower reflectors and the heat dissipation ring 16 are integrated into one structure, which reduces the number of parts, and the heat collecting cover 9 is pressed on the limit step, which has a simple structure and is easy to install.

Embodiment 3

[0079] like Figure 7 As shown, what is different from the first embodiment is the structure of the lower reflector 12 , and other contents are the same as those of the first embodiment.

[0080] The lower reflector 12 and the heat insulating plate 14 have an integrated structure to form an integrated air intake heat insulating plate. A limit step is provided above the protective cover 8 , and the air intake heat insulating plate compresses the heat collecting cover 9 on the limit step.

[0081] It can be understood that the lower reflector 12 and the heat dissipation ring 16 are integral structures.

[0082] It can be understood that the upper reflector 11 and the heat dissipation ring 16 are integrally formed.

[0083] It can be understood that the heat collecting cover 9 is installed between the protective cover 8 and the reflector.

[0084] It can be understood that the heat collecting cover 9 is installed on the reflector or protective cover 8 .

[0085] To sum up, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com