Air purification device for sintering flue gas dust removal system

An air purification device and dust removal system technology, applied in the field of air purification, can solve the problems of low degree of automation and efficiency, inconvenient control and operation, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

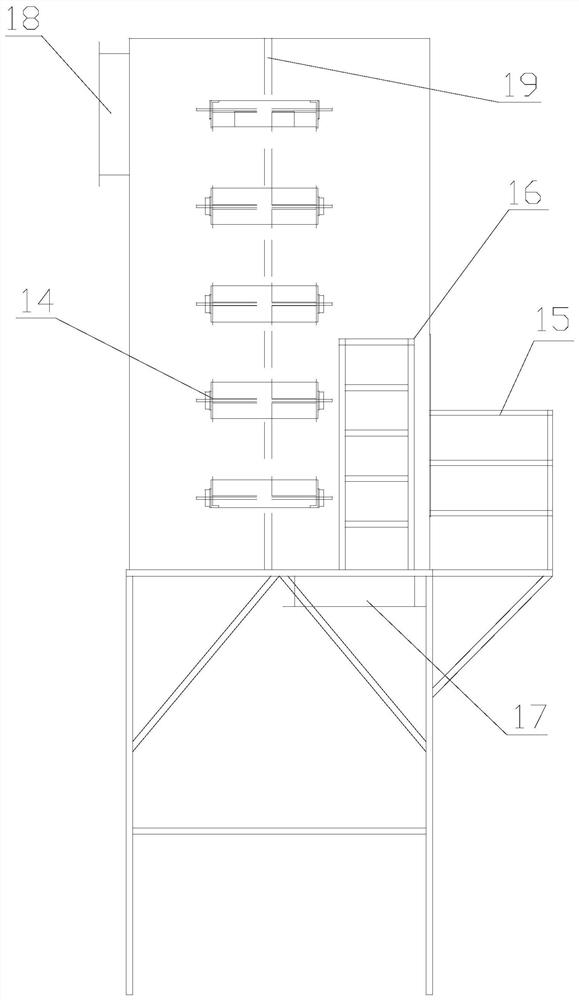

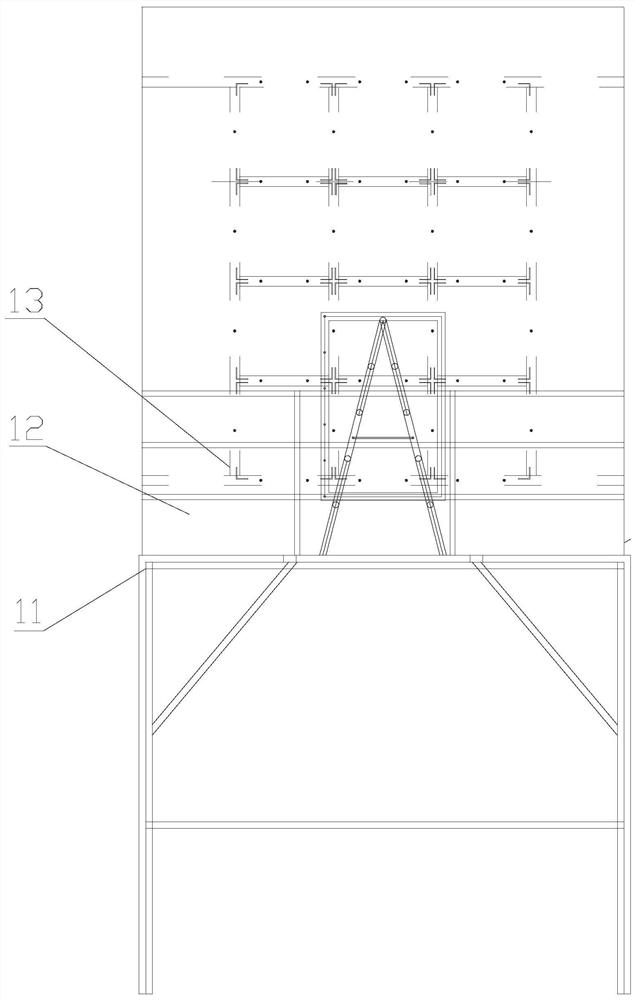

[0017] like figure 1 and figure 2 As shown, an air purification device for a sintering flue gas dust removal system includes a bracket 11 and a housing 12. The housing 12 is provided with a filter chamber, and the filter chamber is provided with a drawer-type removable filter box 14, and the filter box 14 passes through The mounting frame 13 is connected to the housing 12; an air inlet 17 is arranged under one side of the housing 12, an air outlet 18 is arranged above the other side of the housing, and a plurality of filter boxes 14 are longitudinally arranged in the air flow direction in the filter chamber; The lower filter box is the first filter box, the upward order is the second filter box, the third filter box, and the uppermost filter box is the Nth filter box. The filter box 14 is composed of a bracket, a base cloth and a filter cloth. The base cloth includes grid-like plain weave cloth or non-woven fabric. The filter cloth includes high-performance non-woven fabric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com