Method and system for preparing 4N-grade high-purity iron

A high-purity, pure iron technology, applied in the field of preparation of 4N-grade high-purity iron and systems, can solve the problem that it is difficult to reduce metal impurities, and achieve the effect of expanding the reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

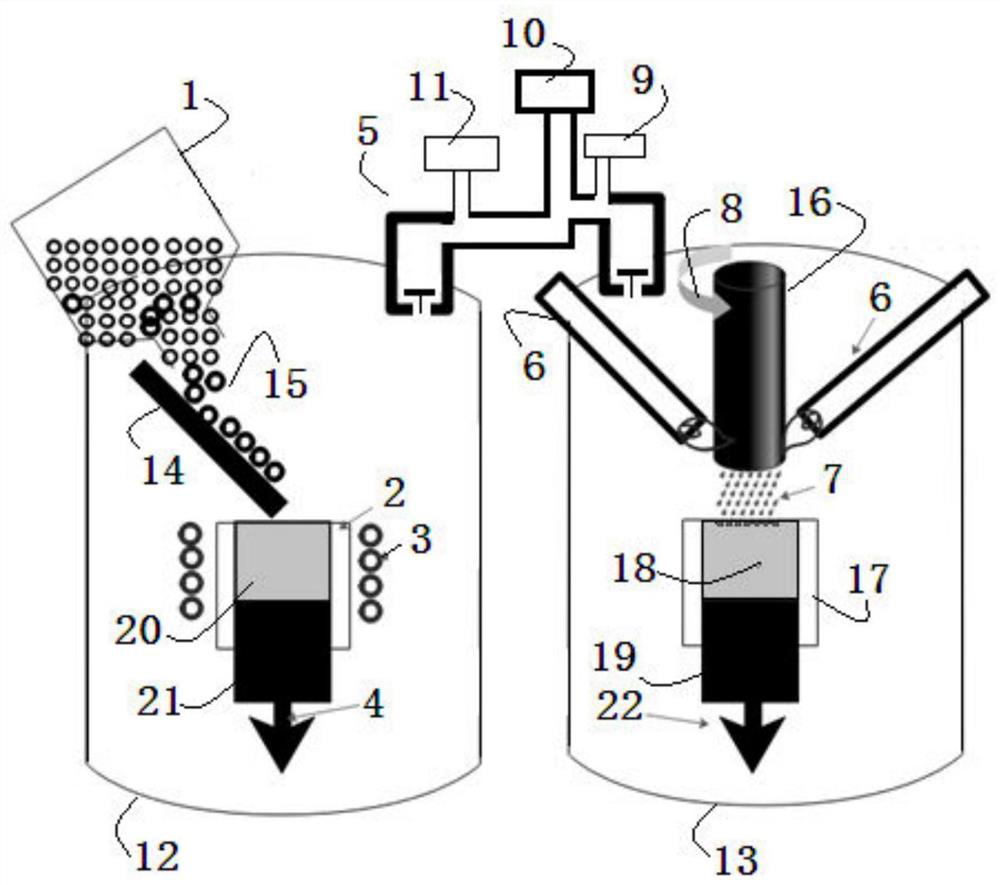

[0039] Example: [1] Prepare electrolytic iron samples, each weighing about 10kg, and put them into the left chamber of the high-purity iron refining furnace; [2] Turn on the circulating cooling water, and check that the cooling pipes are unobstructed; [3] Turn on the mechanical Pump, when the vacuum degree in the furnace is less than 500Pa, start the Roots pump, and after the vacuum degree continues to decrease to 1Pa, start the diffusion pump until the vacuum degree in the furnace reaches 3×10 -3 Pa; [4] Start the feeder, turn on the induction power switch at the same time, melt the electrolytic iron in the water-cooled copper crucible, and observe the melting situation and liquid level of the liquid surface through the observation hole on the furnace, and wait until the liquid level rises to the upper edge of the crucible At 2cm, start the pulling system and start directional solidification; [5] By adjusting the feeding amount, the induction power power and the pulling speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com