Automatic control system of blast furnace hydraulic tapping machine and blast furnace hydraulic tapping machine

A technology of automatic control system and opening machine, applied in the direction of fluid pressure actuating device, mechanical equipment, servo motor, etc., can solve problems such as affecting the production efficiency of blast furnace equipment, large safety risks, increasing production costs, etc., to reduce labor intensity and Safety risk, improve production efficiency, prevent the effect of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings. It is noted that the terms "first", "second" and the like are only for the purpose of facilitating description, and should not be construed as limitations on quantity and nature.

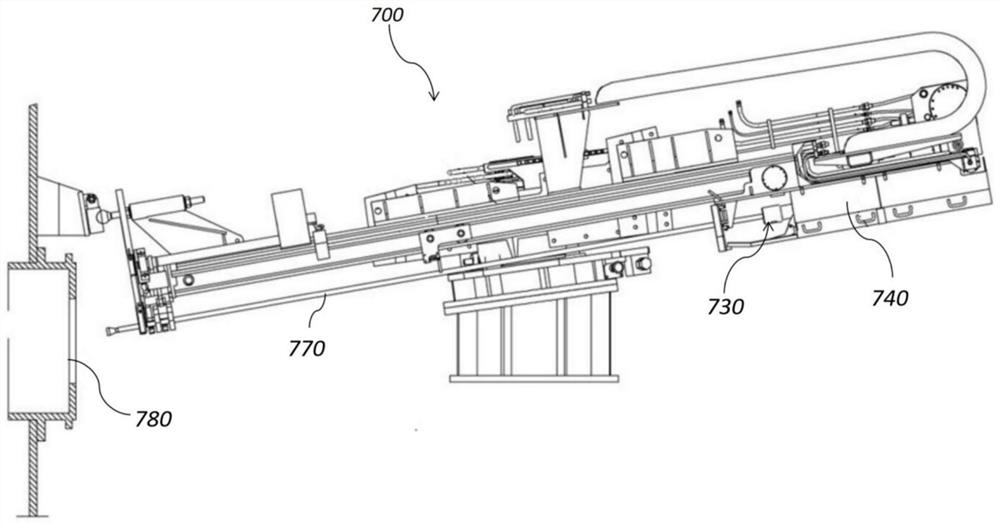

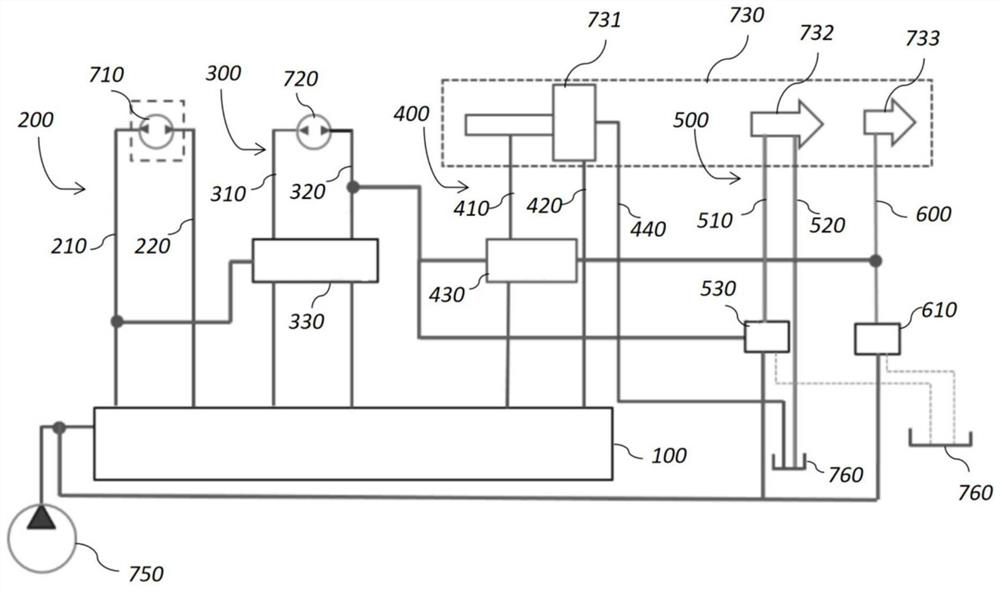

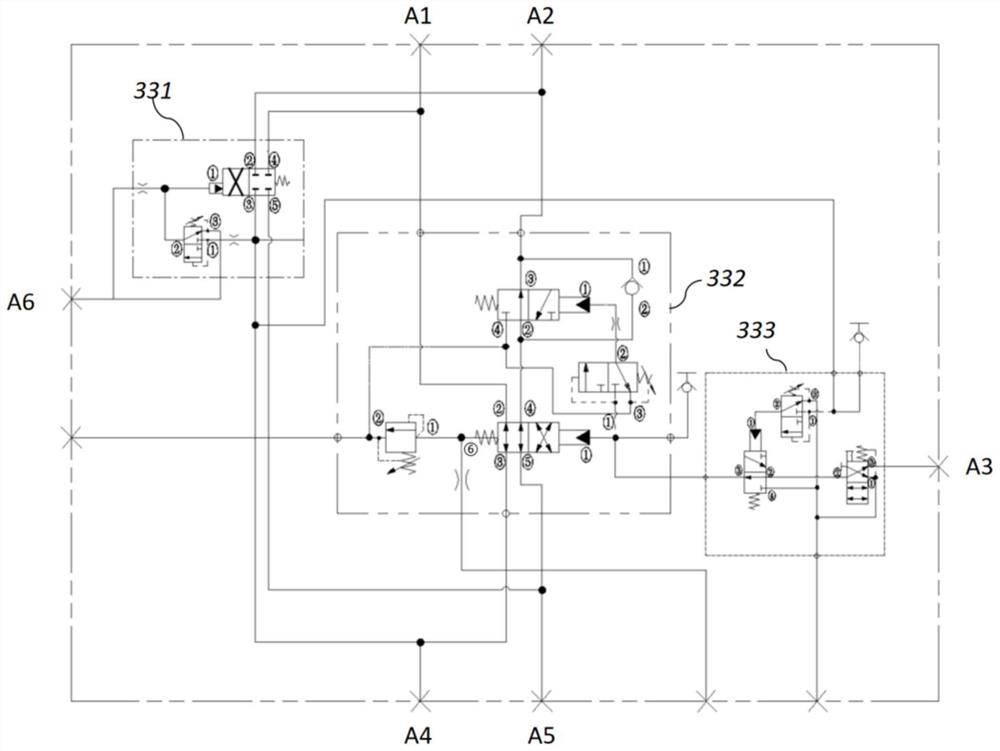

[0047] figure 1 A schematic structural diagram of an existing blast furnace hydraulic opening machine is shown, such as figure 1 As shown, the blast furnace hydraulic opening machine 700 includes a rock drill 730 and a trolley 740 that pushes the rock drilling machine 730; the blast furnace hydraulic opening machine automatic control system provided by the embodiment of the present invention can perform hydraulic control on this type of blast furnace hydraulic opening machine. The trolley 740 is driven by the propulsion motor 720 to achieve forward advancement and retraction, thereby pushing the rock drill 730 to advance and retreat. The drill rod 770 of the rock drill 73...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com