Underwater pipe laying robot and pipe laying method thereof

A robot and pipe-laying technology, which is used in underwater operation equipment, pipes/pipe joints/fittings, motor vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

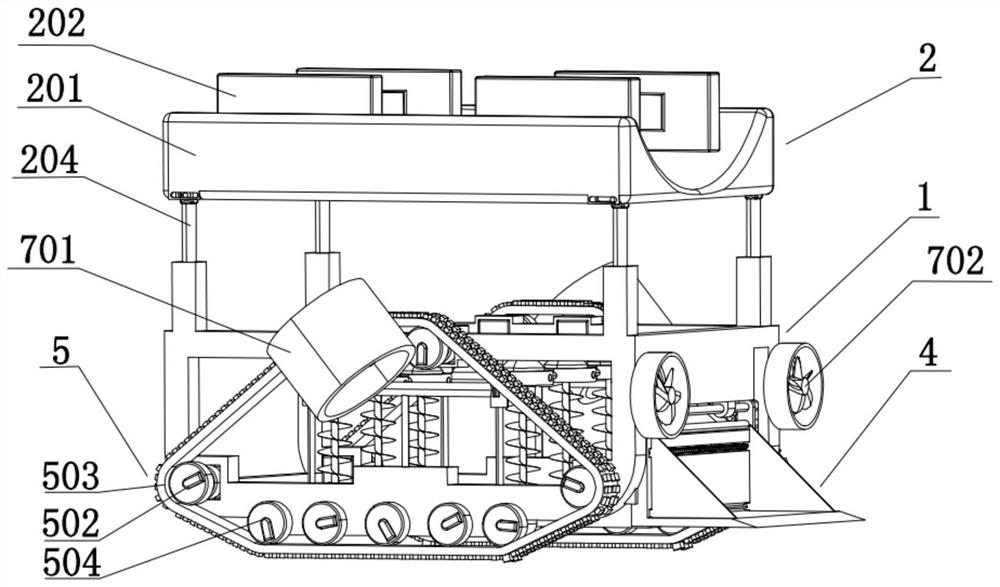

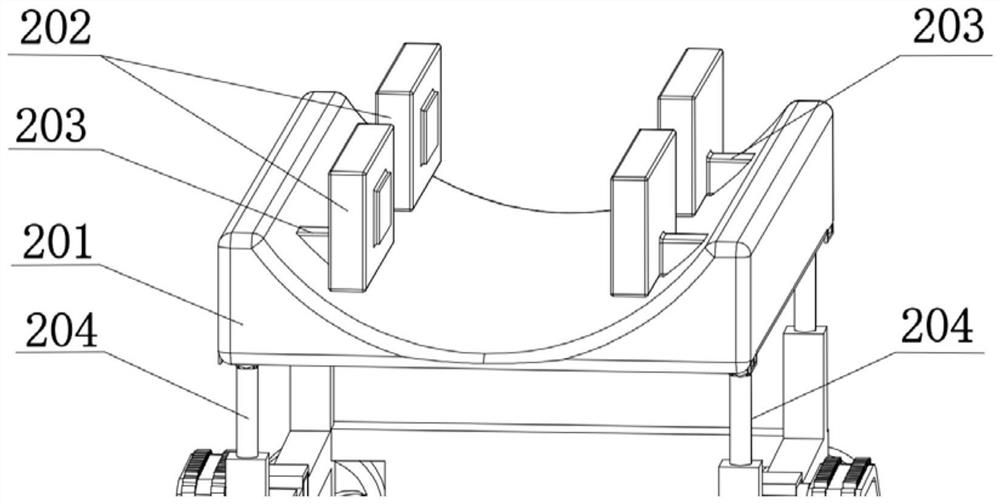

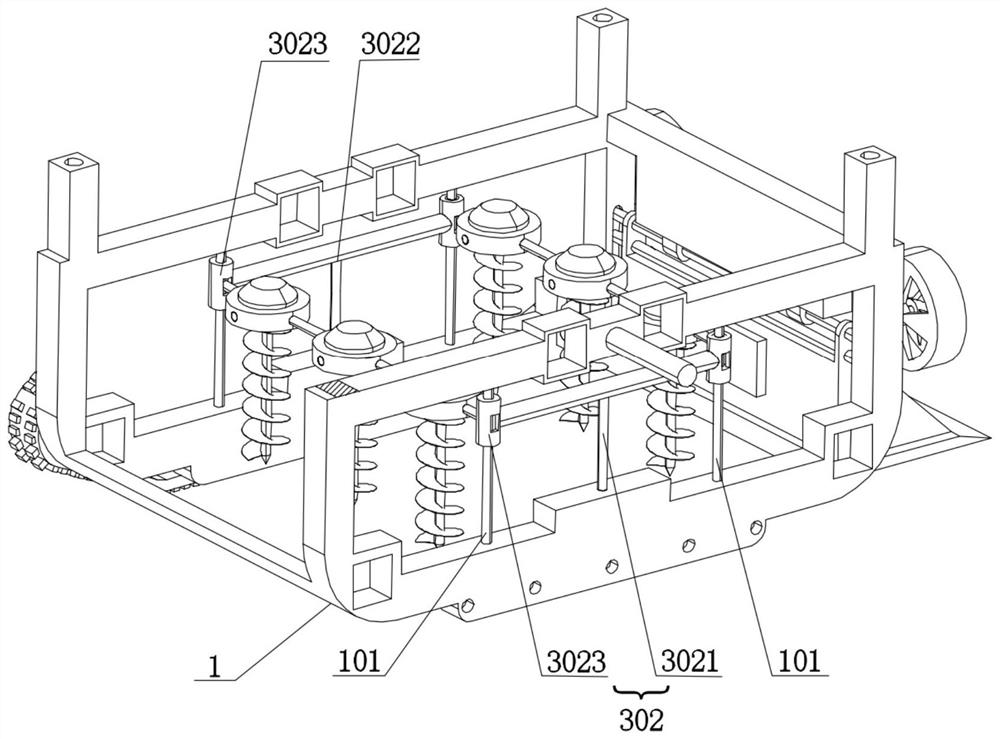

[0065] like figure 1 As shown, this embodiment discloses an underwater pipe-laying robot, including a support structure 1, a pipe-laying adsorption platform 2, a pipeline trench excavation device 3, a dust cleaning device 4, a driving device 5, a crawler adsorption device 6, and a propulsion device 7; The pipe-laying adsorption platform 2 includes a pipe-laying rack 201, several electromagnet clips 202 and a first telescopic structure. The pipe-laying rack 201 is arranged on the top of the bracket structure 1 through several first telescopic structures, and several electromagnet clips 202 pass through a plurality of first telescopic structures. The first telescopic rods 203 are arranged on both sides of the inner wall of the pipe-laying frame 201; the pipeline trench excavation device 3 is arranged at the bottom of the support structure 1, and the pipeline excavation device includes several ground drilling structures 301 and second telescopic structures 302. Several ground dril...

Embodiment 2

[0068] like Figure 1 to Figure 8 As shown, this embodiment, on the basis of Embodiment 1, discloses an underwater pipe-laying robot, including a support structure 1, a pipe-laying adsorption platform 2, a pipe trench excavation device 3, a dust cleaning device 4, a driving device 5, and a crawler belt. The adsorption device 6, the propulsion device 7; the pipe-laying adsorption platform 2 includes a pipe-laying rack 201, several electromagnet clips 202 and a first telescopic structure, and the pipe-laying rack 201 is arranged on the top of the support structure 1 through several first telescopic structures, Several electromagnet clips 202 are arranged on both sides of the inner wall of the pipe-laying frame 201 through the first telescopic rods 203; the pipeline trench excavation device 3 is arranged at the bottom of the support structure 1, and the pipeline excavation device includes several ground drilling structures 301 and a second telescopic structure 301. Structure 302,...

Embodiment 3

[0085] like Figure 10 As shown, this embodiment, on the basis of Embodiment 2, discloses a pipe laying method of an underwater pipe laying robot, comprising the following steps:

[0086] S1: The underwater pipe-laying robot is adsorbed on the mother ship through the crawler adsorption device 6, and walks on the surface of the mother ship;

[0087] S2: Disconnect the power system of the crawler adsorption device 6, and the underwater pipe-laying robot cancels the adsorption on the surface of the mother ship, so that the mother ship can drop the underwater pipe-laying robot in the ideal placement position;

[0088] S3: The propulsion device 7 operates to push the underwater pipe-laying robot to move in the water;

[0089] S4: The underwater pipe-laying robot moves to the pre-laying position on the seabed through the driving device 5;

[0090] S5: The pipeline trench excavation device 3 drives the ground drilling structure 301 to loosen soil on the seabed according to the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com