Garbage treatment device and method

A garbage disposal device, technology of garbage, applied in the direction of combustion method, steam engine device, combustion type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

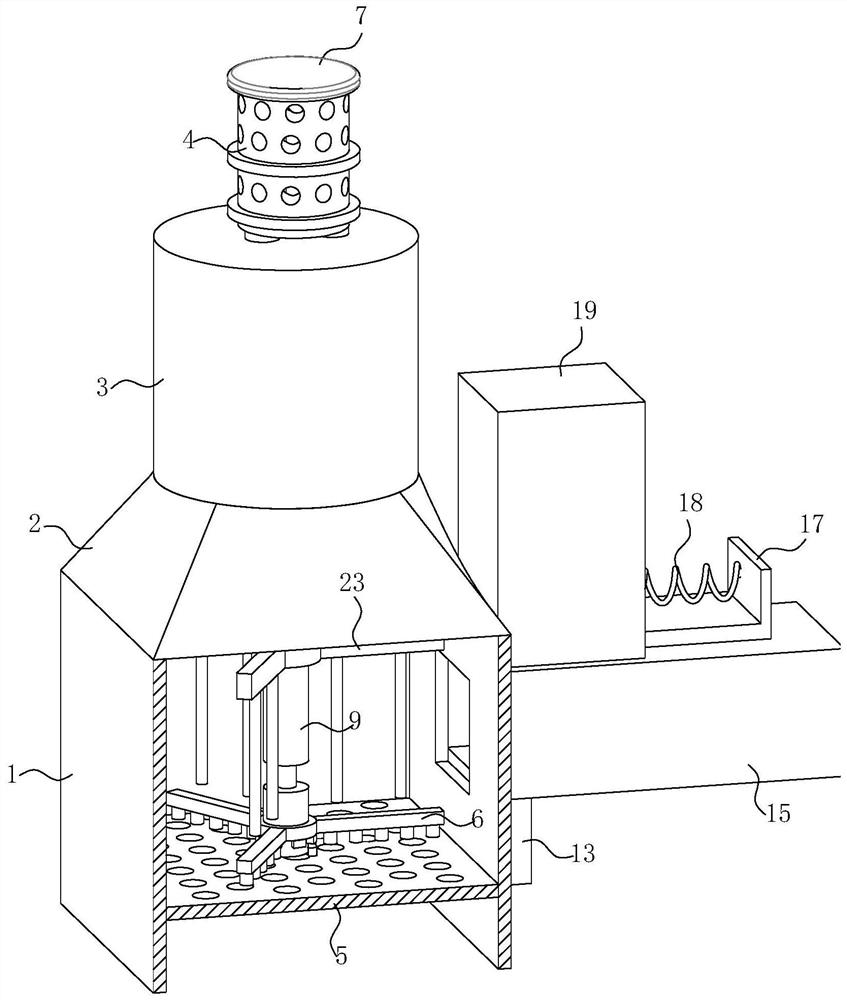

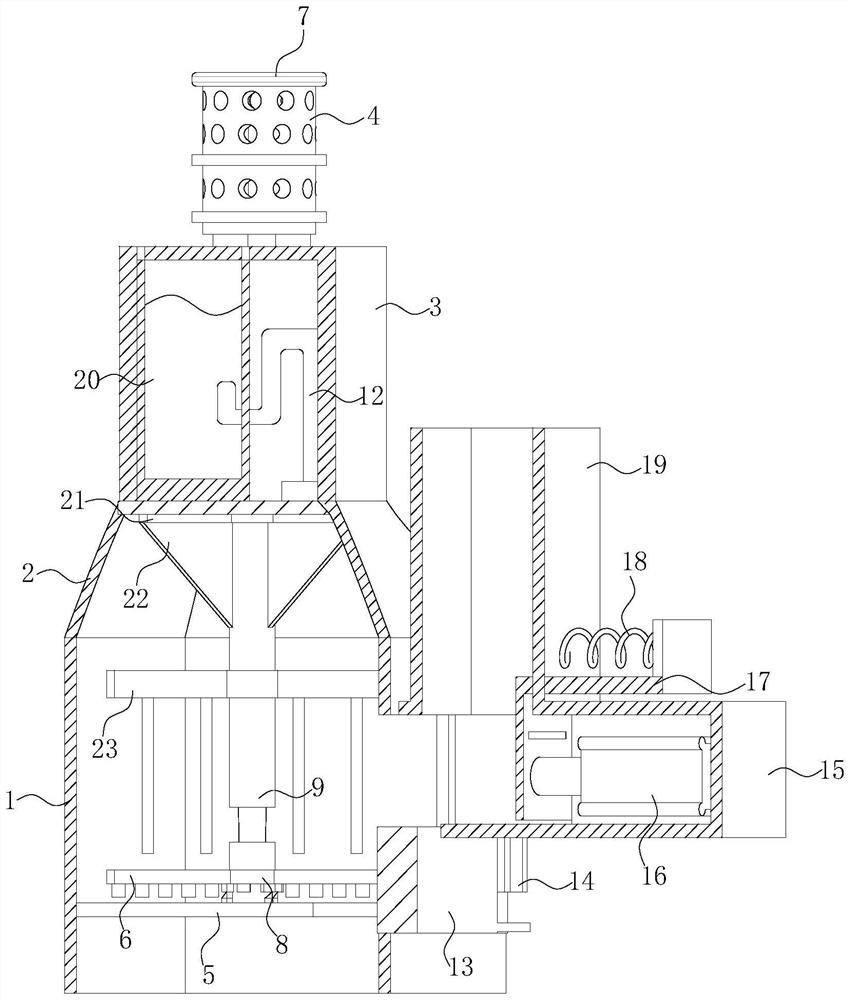

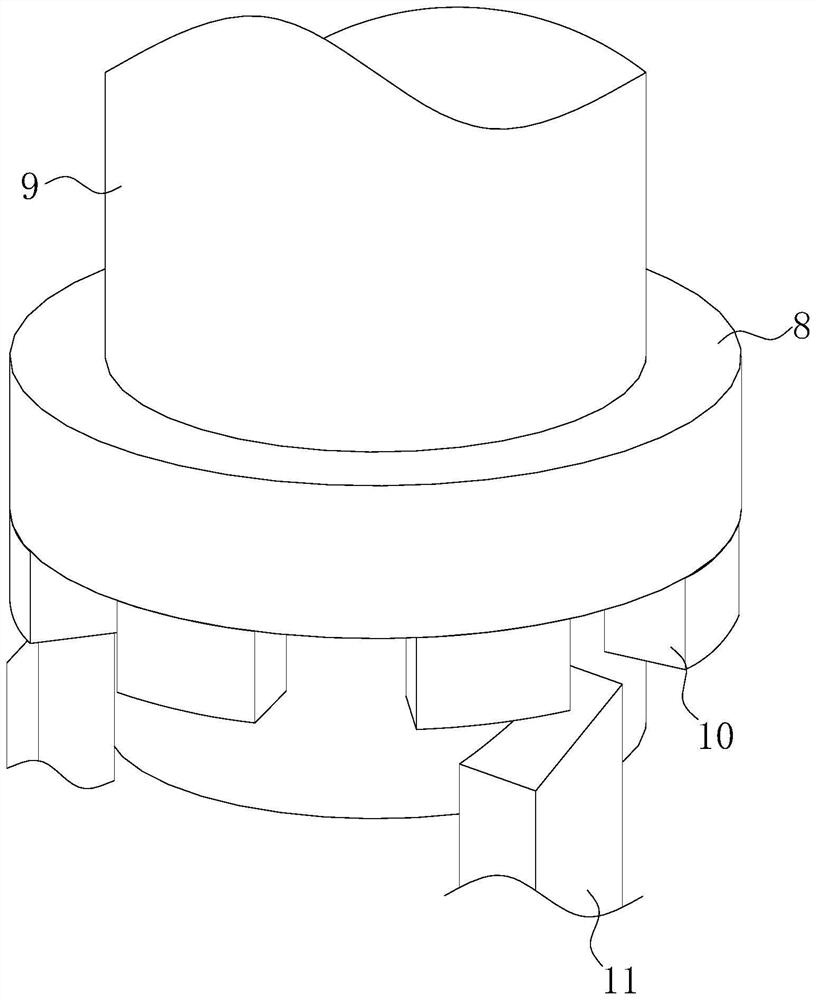

[0025] see Figure 1-4 , the present invention provides a technical solution: a garbage disposal device, comprising a combustion furnace 1, a gas guide table 2 is fixedly connected to the upper end of the combustion furnace 1, and a purification cylinder 3 is fixedly connected to the upper end of the gas guide table 2, The upper end of the purification cylinder 3 is fixedly connected with a releaser 4; the lower end of the combustion furnace 1 is fixedly connected with a partition plate 5, and the partition plate 5 is overlapped with a plurality of through-hole strips 6 distributed in a circular array. Each of the through-hole bars 6 is fixedly connected with a fixing ring 8 , and the fixing ring 8 is fixedly connected with a telescopic rotating shaft 9 , and a stirring rod 23 is fixedly connected to the telescopic rotating shaft 9 , and a turbine is fixedly connected to the telescopic rotating shaft 9 Leaf 22, the upper end of the telescopic shaft 9 is rotatably connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com