Intelligent calibrating device for fuel dispenser

A technology for verification devices and fuel dispensers, which is applied to measuring devices, testing/calibrating devices, and collaborative work devices, etc., which can solve the problems of low work efficiency, data cheating, and the inability to automatically identify the number of the oil gun and the corresponding product number of the fuel oil tanker and other issues to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

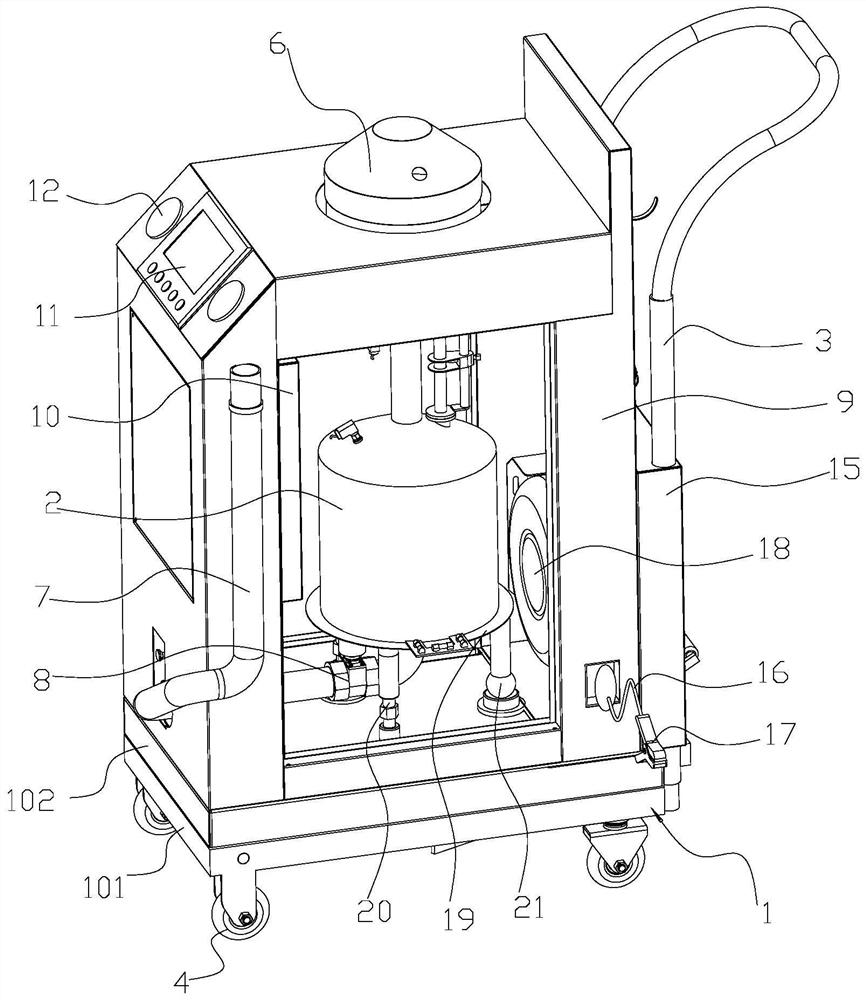

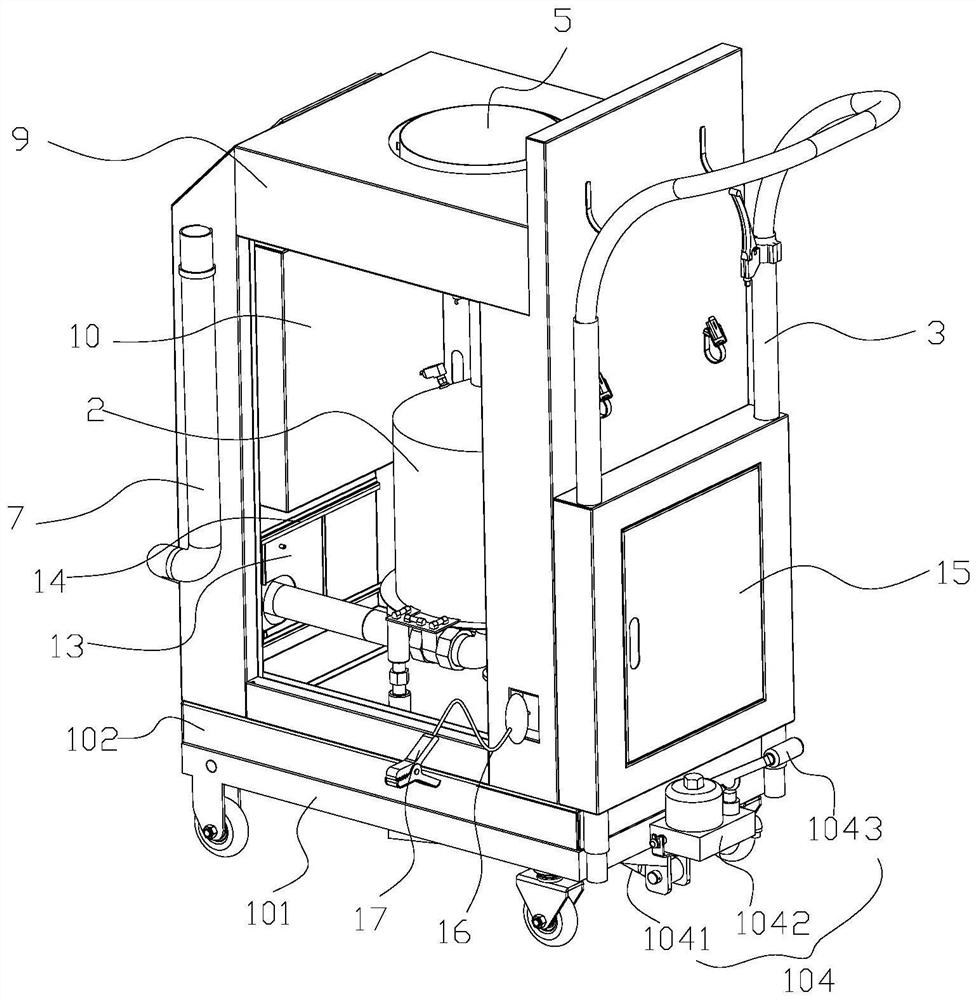

[0036] Please refer to Figure 1 to Figure 4 As shown, this embodiment provides an intelligent verification device for a fuel dispenser, including a standard metal gauge 2, the bottom of the standard metal gauge 2 is provided with an oil drain 7, the top is provided with an overflow cover 5, and the overflow cover 5 is provided with Connect the oil inlet pipe.

[0037] In this embodiment, the intelligent verification device for the fuel dispenser further includes a passive RFID electronic tag, which is placed inside the plastic gun holster of the fuel gun, and the passive RFID electronic tag can also be protected by the plastic gun holster. Passive RFID electronic tags are preset with corresponding gun number and oil number information.

[0038]A radio frequency card reader is installed on one side of the overflow hood. The radio frequency card reader can read passive RFID electronic tag information. The intelligent verification device of the fuel dispenser has a built-in mai...

Embodiment 2

[0042] Please refer to Figure 1 to Figure 4 As shown, this embodiment provides an intelligent verification device for a fuel dispenser, which is basically the same as the first embodiment, with the main difference being that the above-mentioned standard metal gauge 2 is installed on a hydraulically controlled lifting platform 1 .

[0043] specific:

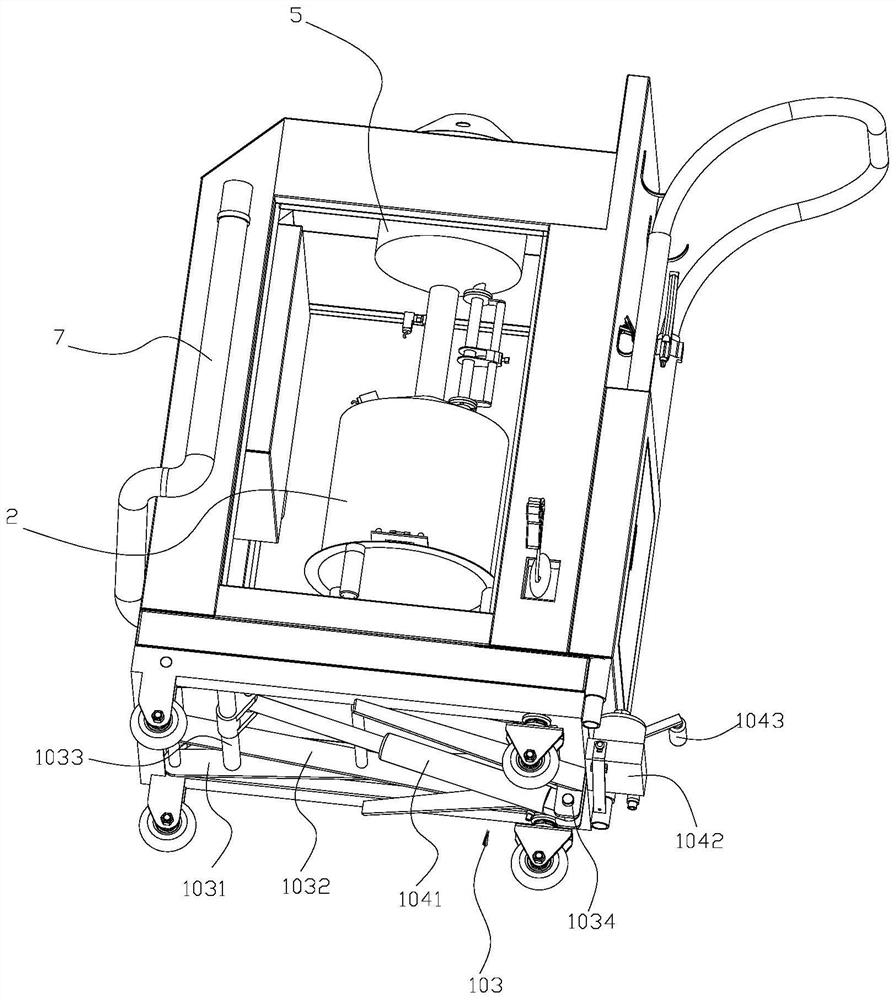

[0044] The above-mentioned lifting platform 1 includes a bottom frame 101, a top plate 102, a scissor assembly 103 and a power assembly 104. Wherein, the bottom frame 101 is a square frame structure, and the four bottom corners of the bottom frame 101 are equipped with universal rollers 4 . At the same time, a push handle 3 is integrally formed on one side of the bottom frame 101 , and the entire verification device can be pushed to move to any position by holding the push handle 3 with both hands.

[0045] The aforementioned scissor assembly 103 is installed between the bottom frame 101 and the top plate 102 , and the scissor ...

Embodiment 3

[0050] see Figure 1 to Figure 4 As shown, this embodiment provides an intelligent verification device for a fuel dispenser, which is basically the same as Embodiment 1 or Embodiment 2, and the main differences are:

[0051] In this embodiment, in this embodiment, the lifting platform 1 is further provided with a box body 9 for protecting the standard metal measuring device 2 .

[0052] specific:

[0053] The side of the above-mentioned box body 9 close to the push handle 3 is a back plate, and a tool box 15 is arranged on the back plate. The tool box 15 is integrally formed with two guide cylinders, one left and one right are arranged in parallel, and the tool box 15 passes through the guide cylinder. It is sleeved on the push handle 3, so that the lifting platform 1 can use the socket connection relationship between the tool box 15 and the push handle 3 during the lifting process to guide the lifting of the platform.

[0054] Further, door frames are provided on the left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com