Packaging material for LED packaging and LED

A technology of LED packaging and packaging materials, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as LED glue cracking and dead lights, and achieve the effects of prolonging service life, reducing water vapor, and solving LED glue cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

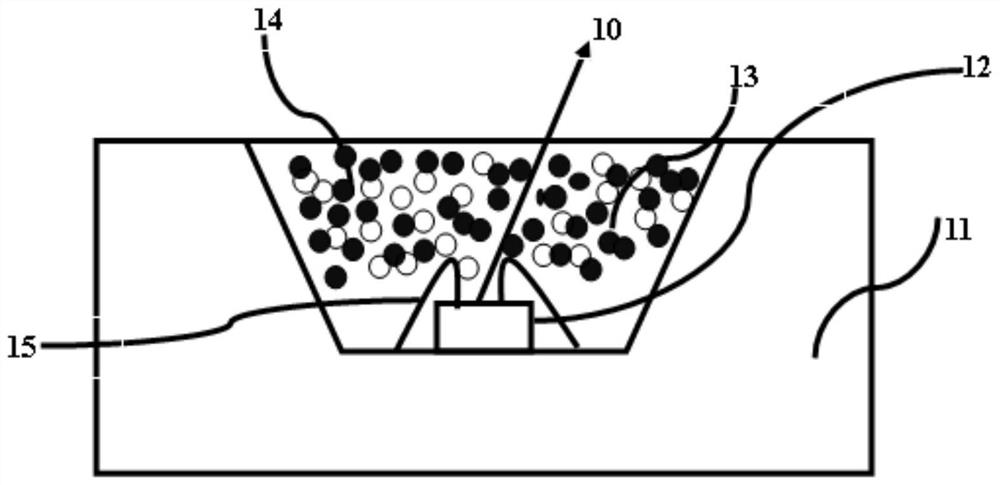

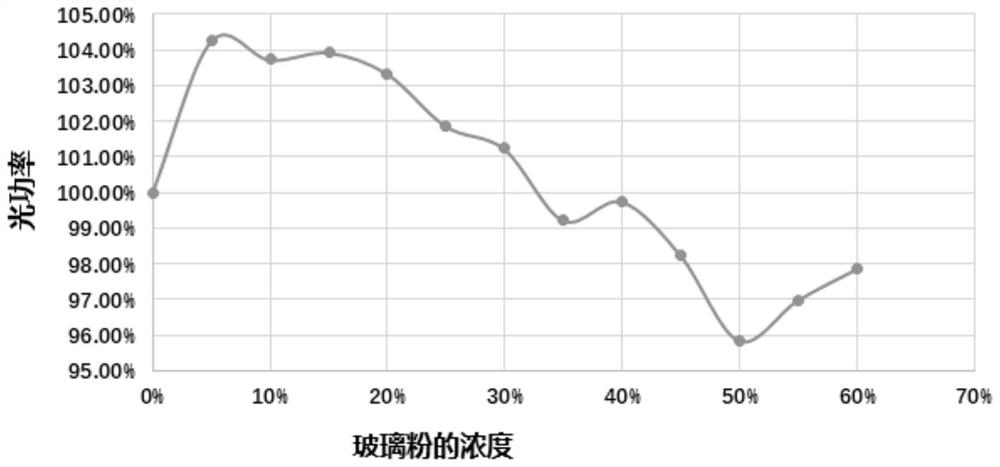

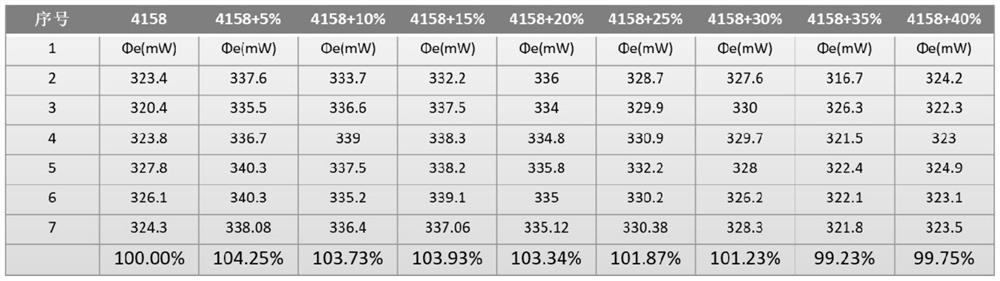

[0043] The model of lamp beads used in the LED package is 3030, the refractive index of silica gel is 1.545, the model is BQ-4158, the dispersant used is sodium hexametaphosphate, and the mass ratio of sodium hexametaphosphate to silica gel is 1%. Powder is SiO 2 E8000, the particle size is 3-5nm; the mass ratio of glass powder to silica gel is 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40% of the packaging materials. When the concentration increases, it cannot be leveled after centrifugation, has no fluidity, and cannot complete the LED packaging. At the same time, too much glass powder will also affect the adhesive force and fluidity of the glue, so 40% is the highest concentration that can be achieved. Through dispensing, centrifugation and other processes, the sample is evenly coated on the chip.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com