A kind of micro-chip light-emitting diode and its production process

A technology for light-emitting diodes and production processes, applied in electrical components, electrical solid-state devices, circuits, etc., can solve problems such as reducing product reliability, susceptibility to uneven force, and overflowing glue, improving bonding strength and avoiding high defect rates. , the effect of high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

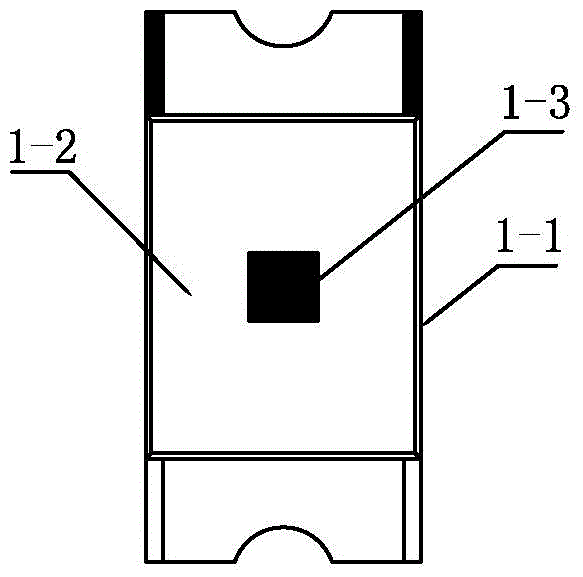

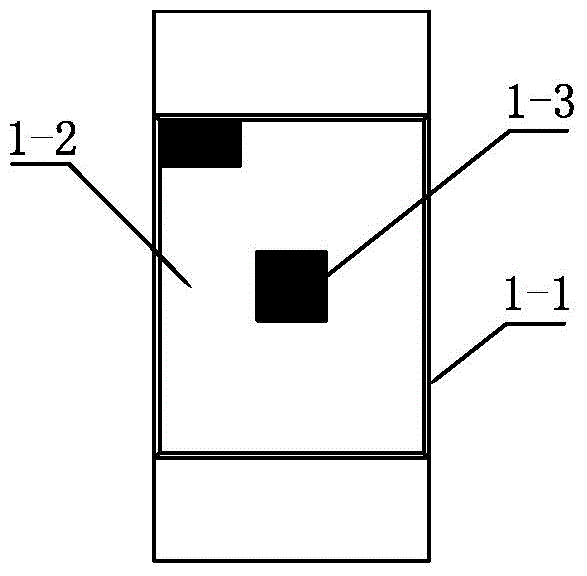

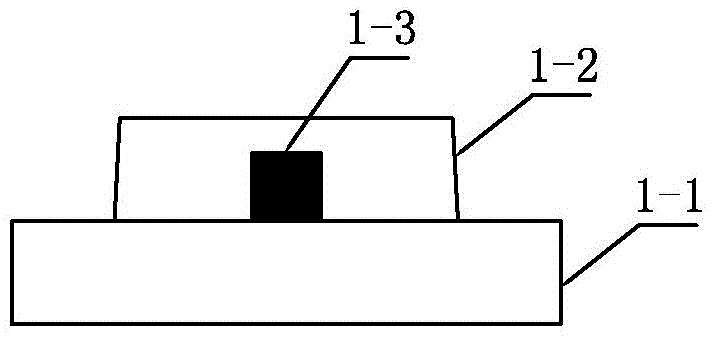

[0043] Such as Figure 4-5As shown, a micro-chip light-emitting diode, including a substrate 1, a light-emitting chip 3 fixed on the substrate 1, and a colloid 2 covering the entire upper surface of the substrate 1, the via hole of the substrate 1 is filled with ink, The electrodes of the light-emitting chip 3 are connected to the substrate 1 through an arc-shaped wire 4. In this embodiment, the electrodes of the light-emitting chip 3 are located in the middle of the upper surface of the light-emitting chip 3. The beginning of the arc-shaped wire 4 is connected to the electrode of the light-emitting chip 3, and the end It is connected to the metal layer 12 of the substrate 1 by twice balling, and the distance between the highest point of the arc-shaped wire 4 and the surface electrode of the light-emitting chip 3 is 80 μm. The tail end of the arc-shaped wire 4 is welded by balling twice, which can strengthen the bonding strength between the arc-shaped wire 4 and the solder spo...

Embodiment 2

[0068] Such as Figure 4-5 As shown, a micro-chip light-emitting diode includes a substrate 1, a light-emitting chip 3 fixed on the substrate 1, and a colloid 2 covering the entire upper surface of the substrate 1, and the via hole of the substrate 1 is filled with resin. The electrodes of the light-emitting chip 3 are connected to the substrate 1 through an arc-shaped wire 4. In this embodiment, the electrodes of the light-emitting chip 3 are located in the middle of the upper surface of the light-emitting chip 3. The beginning of the arc-shaped wire 4 is connected to the electrode of the light-emitting chip 3, and the end It is connected to the metal layer 12 of the substrate 1 by twice balling, and the distance between the highest point of the arc-shaped wire 4 and the surface electrode of the light-emitting chip 3 is 100 μm. The tail end of the arc-shaped wire 4 is welded by balling twice, which can strengthen the bonding strength between the arc-shaped wire 4 and the sold...

Embodiment 3

[0073] Such as Figure 4-5 As shown, a micro-chip light-emitting diode, including a substrate 1, a light-emitting chip 3 fixed on the substrate 1, and a colloid 2 covering the entire upper surface of the substrate 1, the via hole of the substrate 1 is filled with ink, The electrodes of the light-emitting chip 3 are connected to the substrate 1 through an arc-shaped wire 4. In this embodiment, the electrodes of the light-emitting chip 3 are located in the middle of the upper surface of the light-emitting chip 3. The beginning of the arc-shaped wire 4 is connected to the electrode of the light-emitting chip 3, and the end It is connected to the metal layer 12 of the substrate 1 by twice balling, and the distance between the highest point of the arc-shaped wire 4 and the surface electrode of the light-emitting chip 3 is 130 μm. The tail end of the arc-shaped wire 4 is welded by balling twice, which can strengthen the bonding strength between the arc-shaped wire 4 and the solder s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com