Self-walking wheel type walnut picking machine based on single-chip microcomputer control

A single-chip control, picking machine technology, applied in the direction of picking machines, agricultural machinery and implements, harvesters, etc., can solve the problems of increasing the burden of saplings, fixed vibration amplitude, inapplicability, etc., and achieve the effect of ensuring the convenience of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

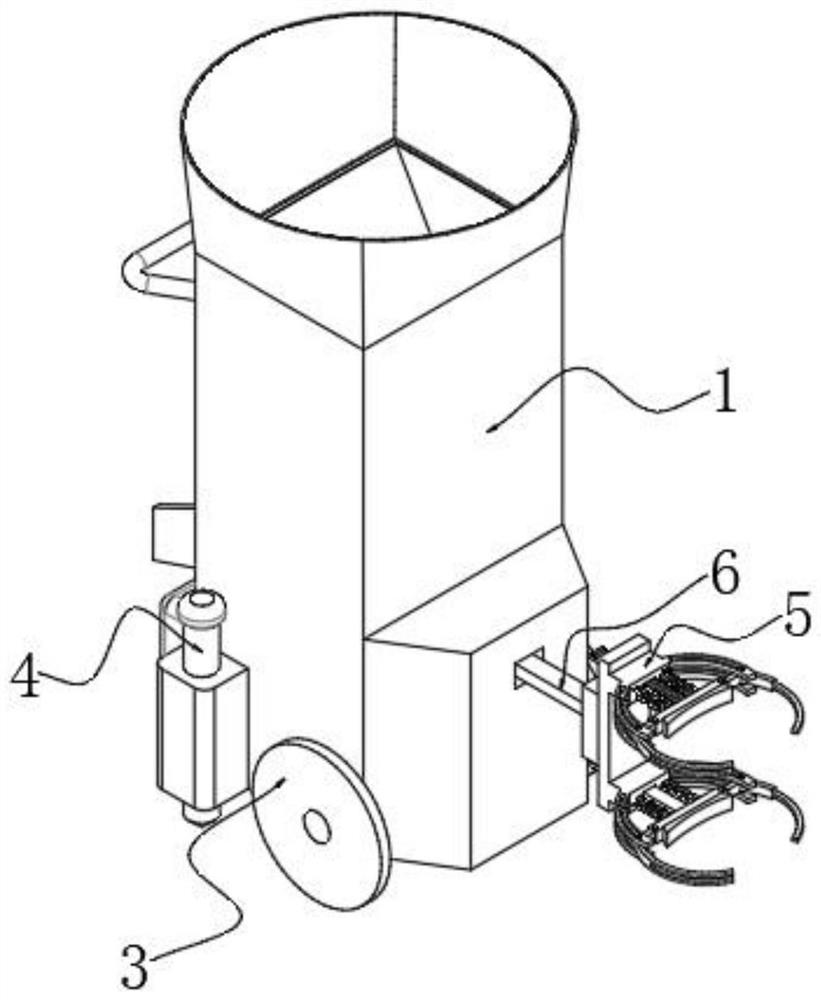

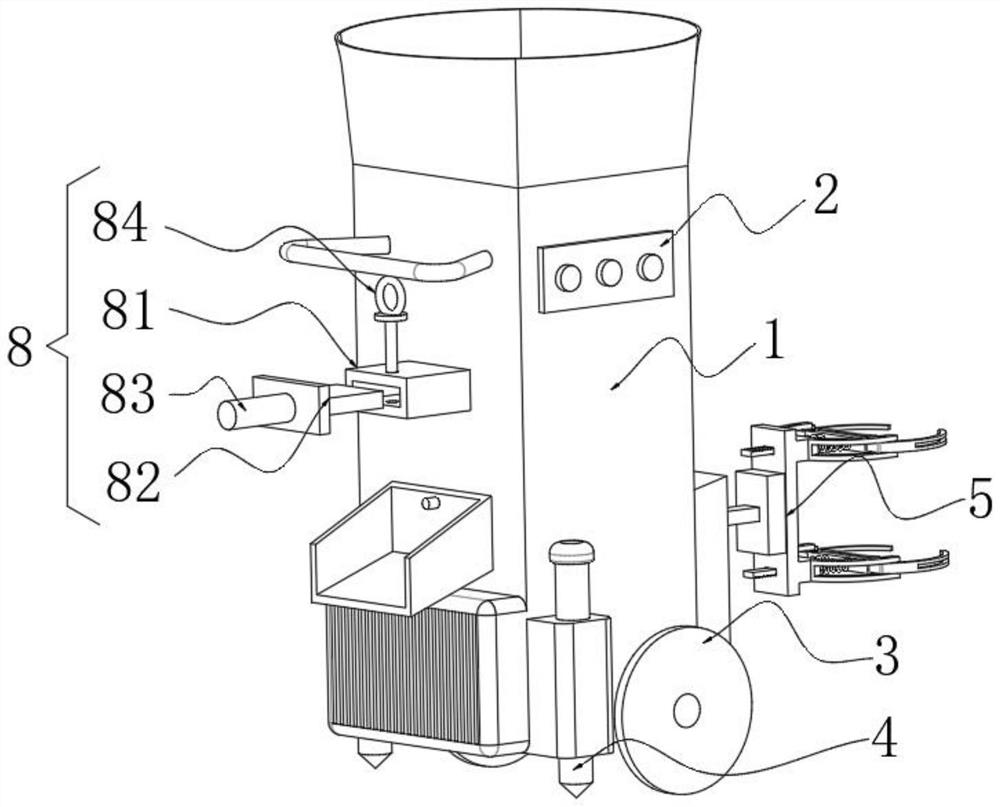

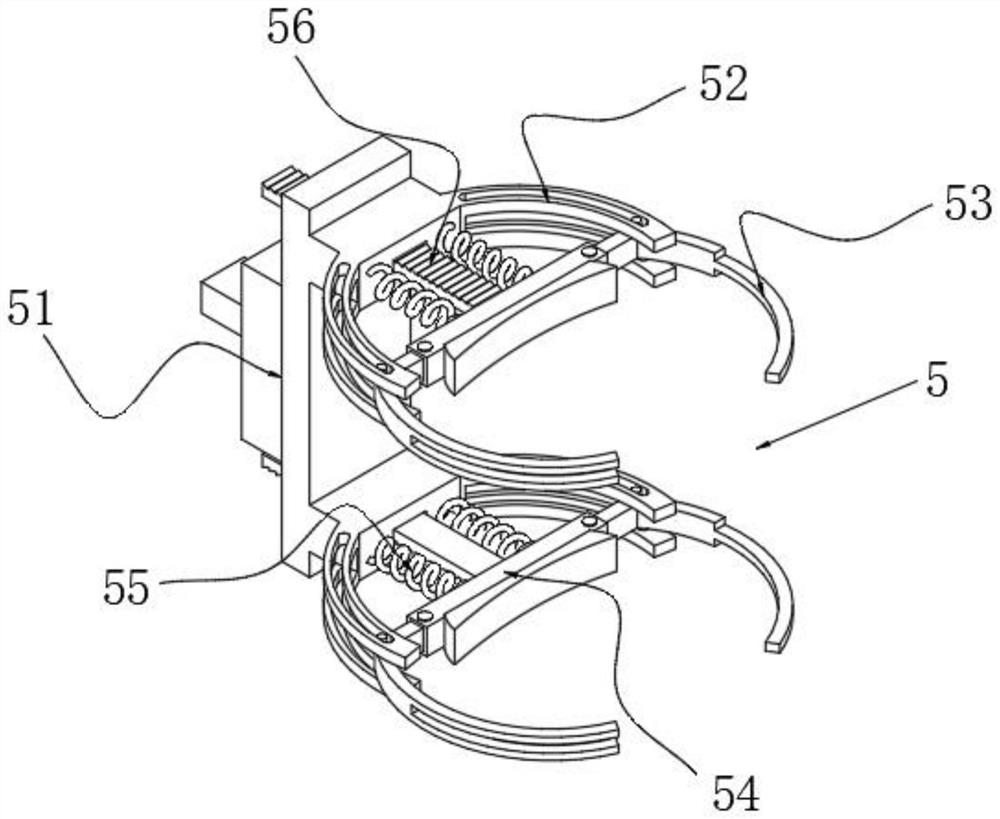

[0035] see figure 1 and Figure 7 , a self-propelled wheeled walnut picking machine based on single-chip control, including a vehicle body 1, a vibration mechanism 7 is arranged inside the vehicle body 1, and the vibration mechanism 7 includes a motor 71 fixedly connected to the inside of the vehicle body 1, and the outside of the motor 71 is A main shaft 72 is fixedly connected, a swash plate 73 is hinged to the outside of the main shaft 72, a telescopic rod 74 is hinged to the outside of the swash plate 73, an adjusting hydraulic pump 75 is hinged to the telescopic rod 74, and an inner bush 76 is slidably connected to the side end of the swash plate 73. , a transmission rod 77 is movably connected to the outside of the inner bushing 76, an active plate 78 is fixedly connected to the side end of the transmission rod 77, a connecting rod 710 is slidably connected to the inside of the active plate 78, and two ends of the connecting rod 710 are fixedly connected to the driven pl...

Embodiment 2

[0047] see Figure 1-5 , a self-propelled wheeled walnut picking machine based on single-chip control, including a vehicle body 1, a vibration mechanism 7 is arranged inside the vehicle body 1, and the vibration mechanism 7 includes a motor 71 fixedly connected to the inside of the vehicle body 1, and the outside of the motor 71 is A main shaft 72 is fixedly connected, a swash plate 73 is hinged to the outside of the main shaft 72, a telescopic rod 74 is hinged to the outside of the swash plate 73, an adjusting hydraulic pump 75 is hinged to the telescopic rod 74, and an inner bush 76 is slidably connected to the side end of the swash plate 73. , a transmission rod 77 is movably connected to the outside of the inner bushing 76, an active plate 78 is fixedly connected to the side end of the transmission rod 77, a connecting rod 710 is slidably connected to the inside of the active plate 78, and two ends of the connecting rod 710 are fixedly connected to the driven plate A vibra...

Embodiment 3

[0060] see Figure 1-7 , a self-propelled wheeled walnut picking machine based on single-chip control, including a vehicle body 1, a vibration mechanism 7 is arranged inside the vehicle body 1, and the vibration mechanism 7 includes a motor 71 fixedly connected to the inside of the vehicle body 1, and the outside of the motor 71 is A main shaft 72 is fixedly connected, a swash plate 73 is hinged to the outside of the main shaft 72, a telescopic rod 74 is hinged to the outside of the swash plate 73, an adjusting hydraulic pump 75 is hinged to the telescopic rod 74, and an inner bush 76 is slidably connected to the side end of the swash plate 73. , a transmission rod 77 is movably connected to the outside of the inner bushing 76, an active plate 78 is fixedly connected to the side end of the transmission rod 77, a connecting rod 710 is slidably connected to the inside of the active plate 78, and two ends of the connecting rod 710 are fixedly connected to the driven plate A vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com