Slag scraping device of circular electrolytic floatation tank

A technology of electrolytic air flotation and slag scraping device, applied in flotation water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of stuck chain, complicated mechanism, easy to corrode, etc. To achieve the effect of reducing load, simple principle and novel structure

Inactive Publication Date: 2018-05-01

合肥挺泰环保科技有限公司

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] With the increasing awareness of environmental protection, the development of sewage treatment has attracted more and more attention. Among them, the sewage treatment process needs to scrape off the impurities in the sewage. The application of this process is mainly reflected in the electrolytic air flotation tank. However, most of the existing slag scraping structures are chain-type, that is, the form of the conveyor belt, which has the defect that the chain type does not correspond to the shape of the circular air flotation pool. The existing measure to solve this problem is to add the conveyor belt wide, which leads to the defect that the chain-type slag-scraping mechanism is too complicated. At the same time, the chain-type slag-scraping device has the defect that debris gets stuck into the chain and sprocket. In addition, the sleeve of the chain-type slag-scraping device Roller chains are expensive and easy to corrode

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

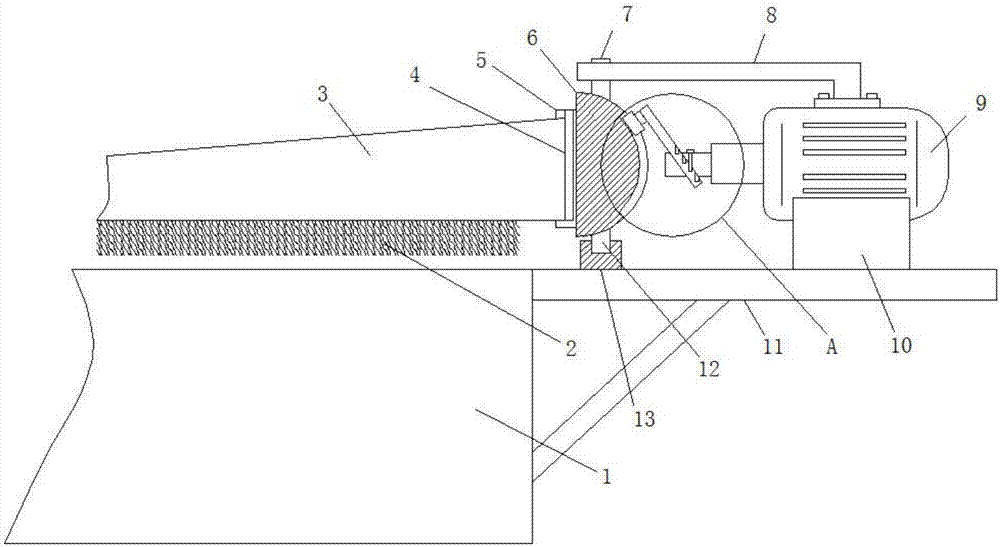

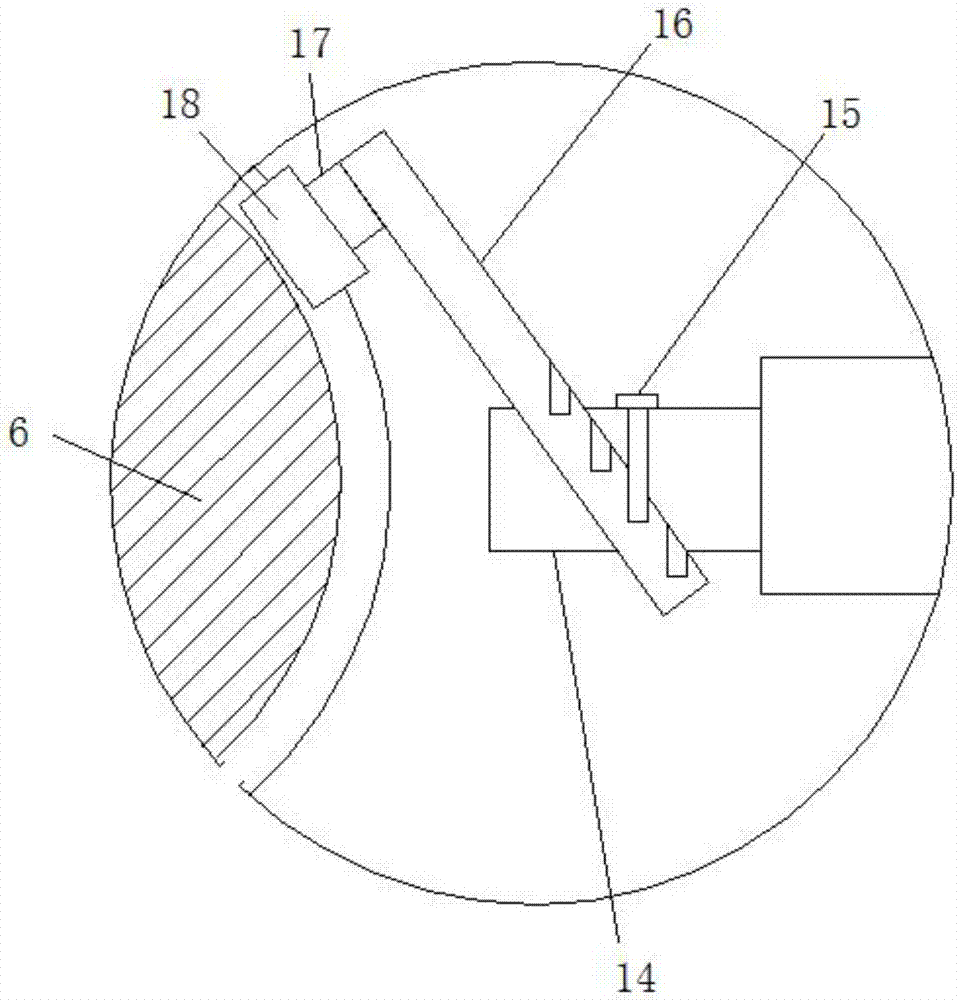

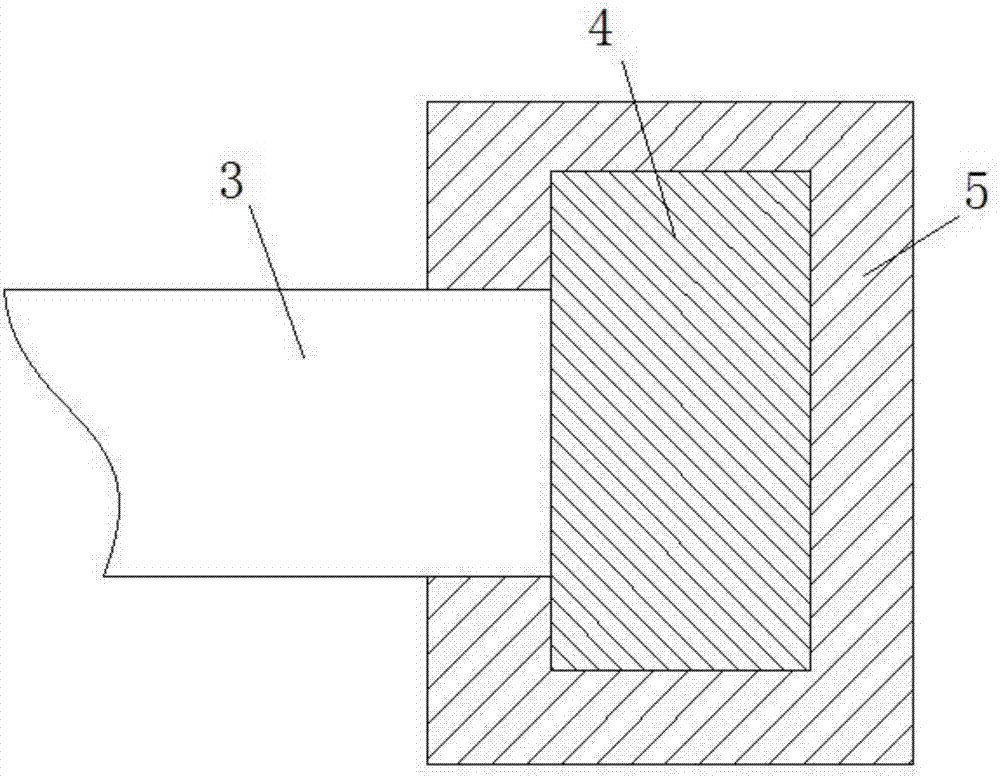

The invention discloses a slag scraping device of a circular electrolytic floatation tank. The slag scraping device comprises a floatation tank, wherein one end of the floatation tank is fixedly connected with a supporting plate; a motor is arranged at the upper side of the supporting plate; the motor is fixedly connected with the supporting plate through a motor frame; an output shaft of the motor is fixedly connected with a fixed shaft; a crank is fixedly inserted in the fixed shaft; the side surface of one end, away from the fixed shaft, of the crank is fixedly connected with a guide column; the upper side of one end, close to the floatation tank, of the supporting plate is fixedly connected with a hinging block; a cam is arranged above the hinging block; the side surface of one end, close to the hinging block, of the cam is fixedly connected with a second side shaft; the second side shaft is hinged to the hinging block; and the side surface of one end, away from the second side shaft, of the cam is fixedly connected with a first side shaft. The slag scraping device disclosed by the invention has the advantages that the structure is novel; a rake hook can swing on the floatationtank by virtue of cooperation between the cam and the crank so as to meet the requirement of a user; and furthermore, the swing amplitude can also be adjusted according to the slag scraping requirement.

Description

technical field [0001] The invention relates to the field of sewage treatment equipment, in particular to a slag scraping device for a circular electrolytic air flotation tank. Background technique [0002] With the increasing awareness of environmental protection, the development of sewage treatment has attracted more and more attention. Among them, the sewage treatment process needs to scrape off the impurities in the sewage. The application of this process is mainly reflected in the electrolytic air flotation tank. However, most of the existing slag scraping structures are chain-type, that is, the form of the conveyor belt, which has the defect that the chain type does not correspond to the shape of the circular air flotation pool. The existing measure to solve this problem is to add the conveyor belt wide, which leads to the defect that the chain-type slag-scraping mechanism is too complicated. At the same time, the chain-type slag-scraping device has the defect that deb...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F1/465

CPCC02F1/46104C02F1/465C02F2201/46105

Inventor 吴小飞

Owner 合肥挺泰环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com