Oil gas recovery method for tanker wharf

A recovery method and technology for oil and gas, applied in separation methods, chemical instruments and methods, recovery of liquid hydrocarbon mixtures, etc., can solve the problems of large oil and gas temperature fluctuations, large energy consumption, and large energy consumption of units, and achieve improved refrigeration energy efficiency and stability. Oil and gas temperature, the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

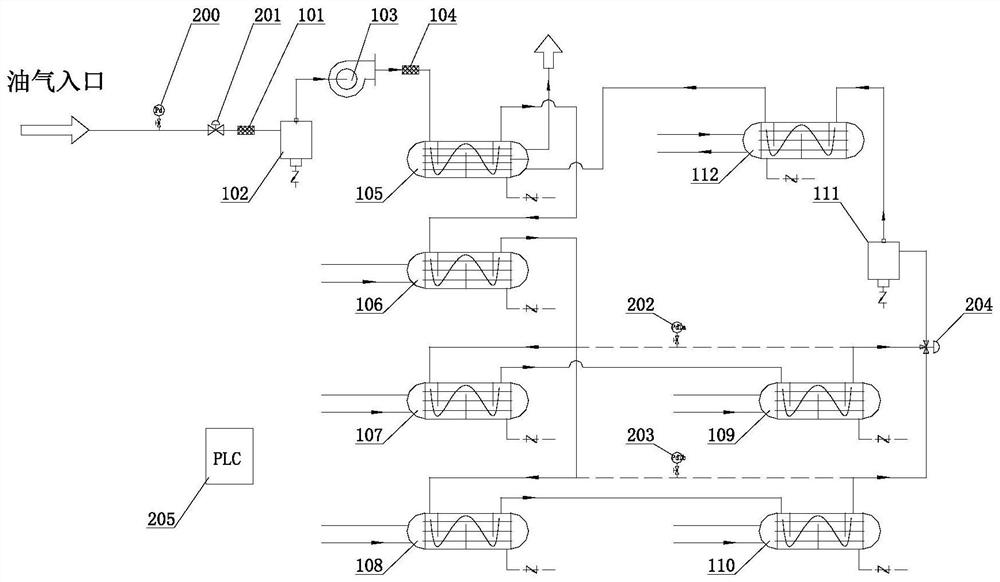

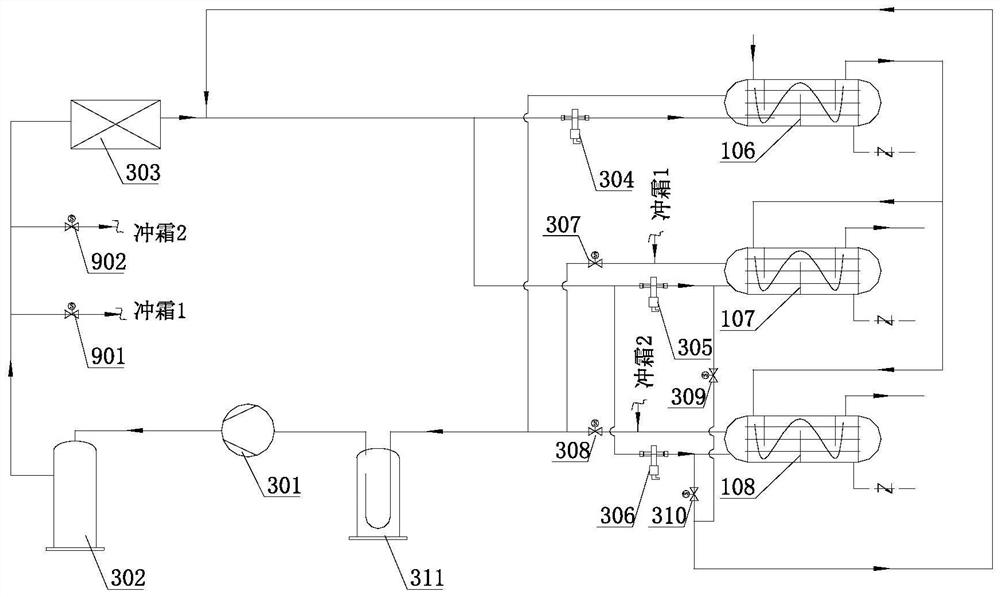

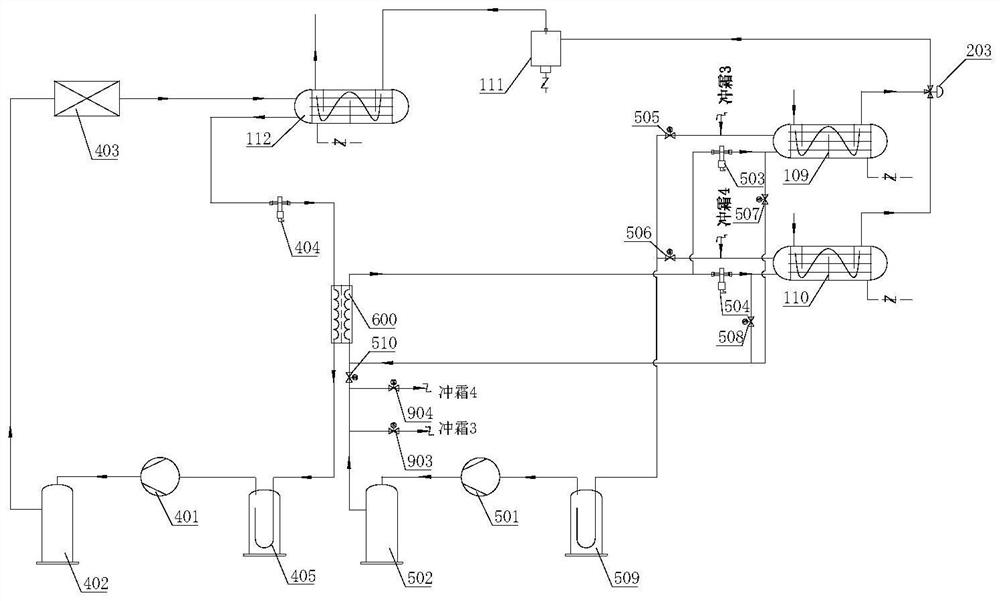

[0038] Example 1: as Figure 1-Figure 3 As shown, the oil and gas recovery method of the oil tanker terminal of the present invention comprises the following steps:

[0039] (S1) The oil and gas to be treated sent from the oil and gas inlet is sent to the oil and gas system, and passes through the regenerative heat exchanger, pre-cooling heat exchanger, shallow cooling heat exchanger, deep cooling heat exchanger and gas-fluorine exchange in the oil and gas system in turn The heat exchanger liquefies the oil and gas by exchanging heat with the refrigerant sent from the refrigeration system, and the oil and gas treated by the gas-fluorine heat exchanger is sent to the regenerative heat exchanger again, and is discharged after heat exchange in the regenerative heat exchanger;

[0040] (S2) The refrigeration system includes a primary refrigeration system, a secondary refrigeration system and a tertiary refrigeration system; the primary refrigeration system sends the refrigerant to...

Embodiment 2

[0071] Example 2: The processing capacity is 300m 3 / h Oil and gas recovery device of oil tanker terminal, oil and gas are volatile oil and gas of refined oil, and the concentration of intake air is 1000g / m 3, the current market equipped terminal oil and gas recovery device is composed of two sets of -70 ℃ single-channel condensing oil and gas recovery systems, the power of the air pump is 5.5kW, the power of the single-channel condensation system is 49.4kW, the total power of the unit is 104.3kW, and the unit energy consumption is 0.348 kW / (m 3 / h).

[0072] The invention 300m 3 / h Oil and gas recovery device at the oil tanker terminal, the final oil and gas temperature is -70℃, the air pump is Shandong Fengyuan explosion-proof Roots air pump with a power of 5.5kW, and the first-stage explosion-proof compressor of the dual-circuit condensing system is the German Bitzer piston compressor 4GE-23Y , power 14.3kW, the second-stage explosion-proof compressor is China Taiwan Fus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com