Transfer tool for diesel generating set machining

A technology for diesel generator sets and transshipment workers, which is applied in the direction of transportation and packaging, packaging food, and assembly machines, etc. It can solve problems such as difficult operation, increase or decrease of equipment, and failure to meet needs, so as to increase the adjustment range, stabilize the transshipment process, and avoid damaged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the specific embodiments, structures, features and effects of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

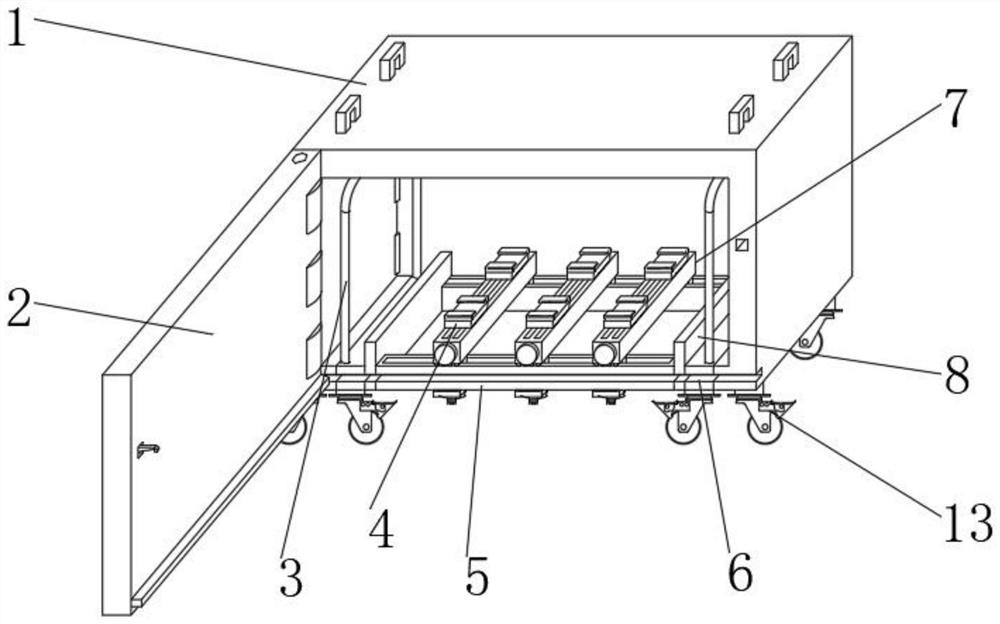

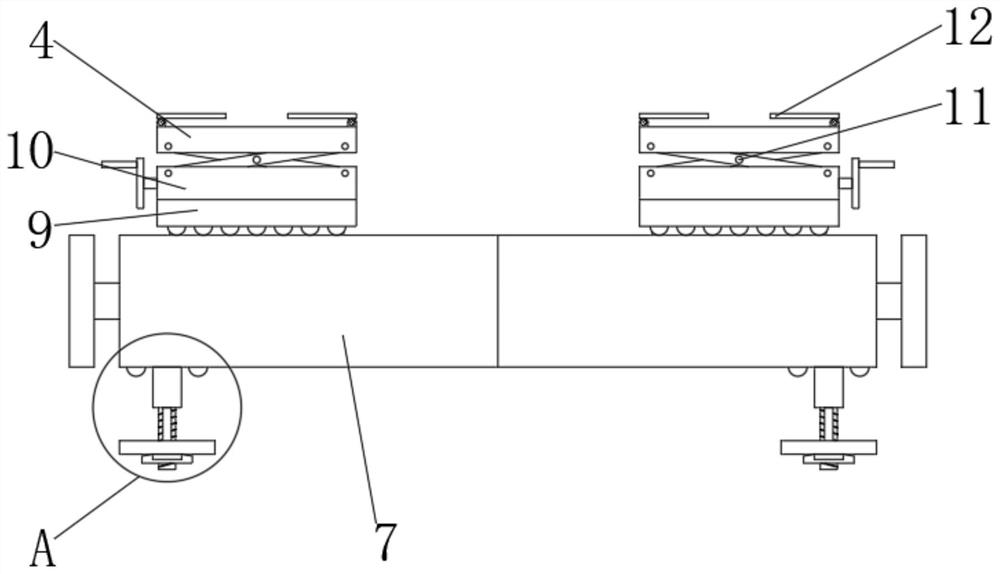

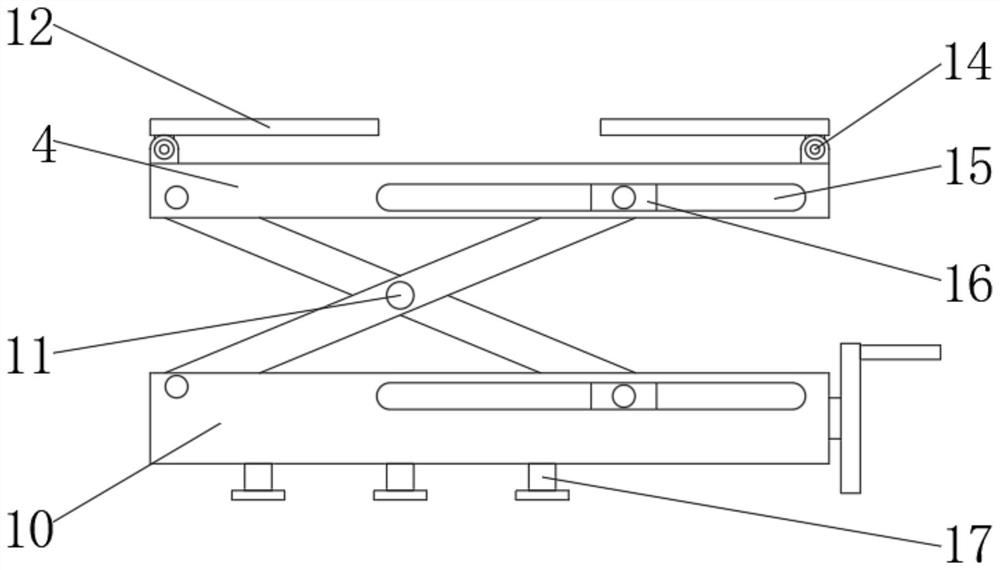

[0028] see Figure 1-5 Shown: a transfer tooling for diesel generator set processing, including a transfer box 1 and a support frame, the support frame includes two connecting plates 8 and two supporting beams 5, the ends of the two supporting beams 5 and the two connecting plates 8 Both are fixedly connected, and the support beam 5 is kept perpendicular to the connecting plate 8, one side of the connecting plate 8 is fixedly connected with a docking slider 6, one side and the bottom of the transfer box 1 are open and set, and one side of the transfer box 1 is hinged with The protective door 2, the inner side walls of the bottom of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap