Integrally-formed wall solidification accelerating device

A technology to accelerate solidification and walls, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of inconvenient moving of heating devices and inconvenient operation, and achieve the effect of accelerating solidification efficiency and reducing the probability of wall rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

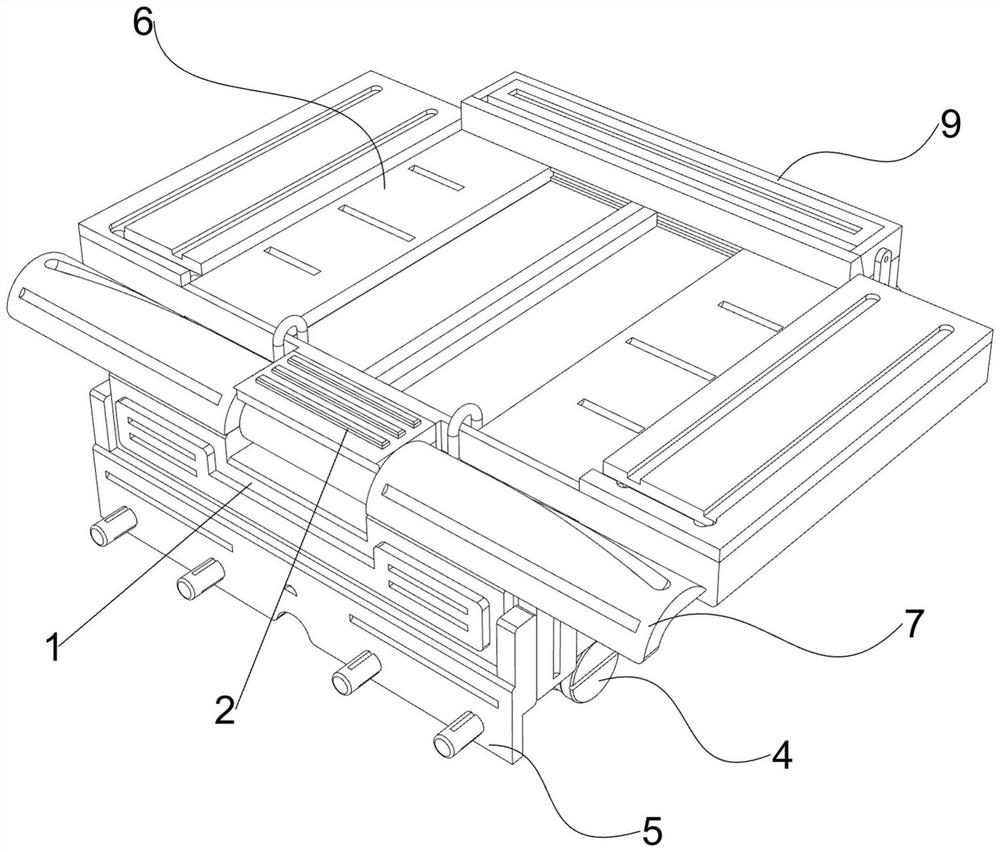

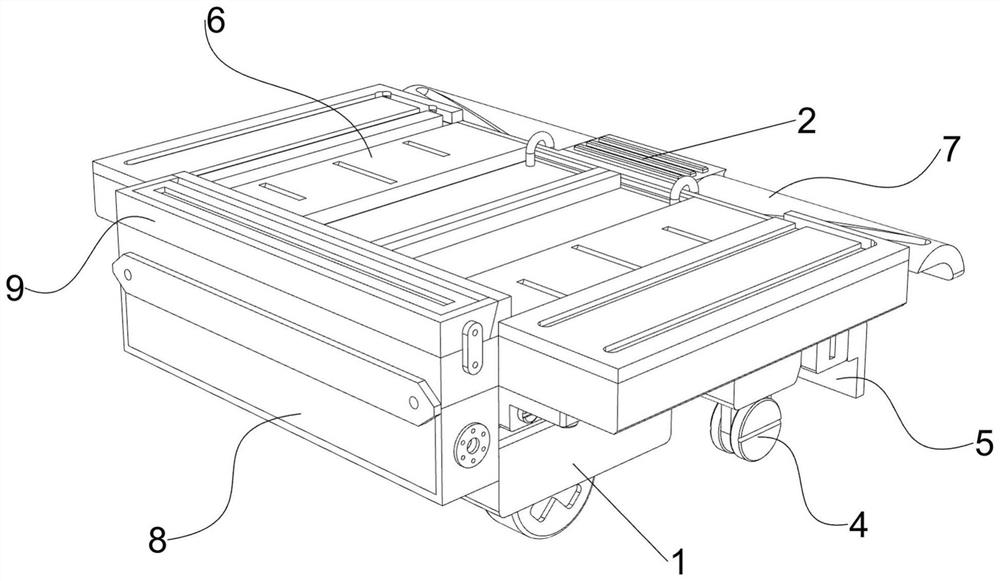

[0036] An integrally formed wall accelerated solidification device, such as Figure 1-7 As shown in the figure, it includes a base 1, a rotating frame 2, a heating tube 3, a moving mechanism 4 and a pushing mechanism 5. The front side of the upper part of the base 1 is rotatably connected with a rotating frame 2. The base 1 can support the device, and the rotating frame 2 A heating pipe 3 is connected to the inner bottom wall, and the heating pipe 3 can heat the wall, so that the wall can be rapidly solidified. The lower side of the base 1 is connected with a moving mechanism 4, which can facilitate the movement of the device. A push mechanism 5 is connected to the side, and the push mechanism 5 can make the rotating frame 2 rotate by itself.

[0037] like figure 1 , figure 2 and Figure 4 As shown, the moving mechanism 4 includes a support block 41, a wheel 42, a fixed block 43, a biaxial motor 44 and a roller 45, two support blocks 41 are welded on the front side of the ...

Embodiment 2

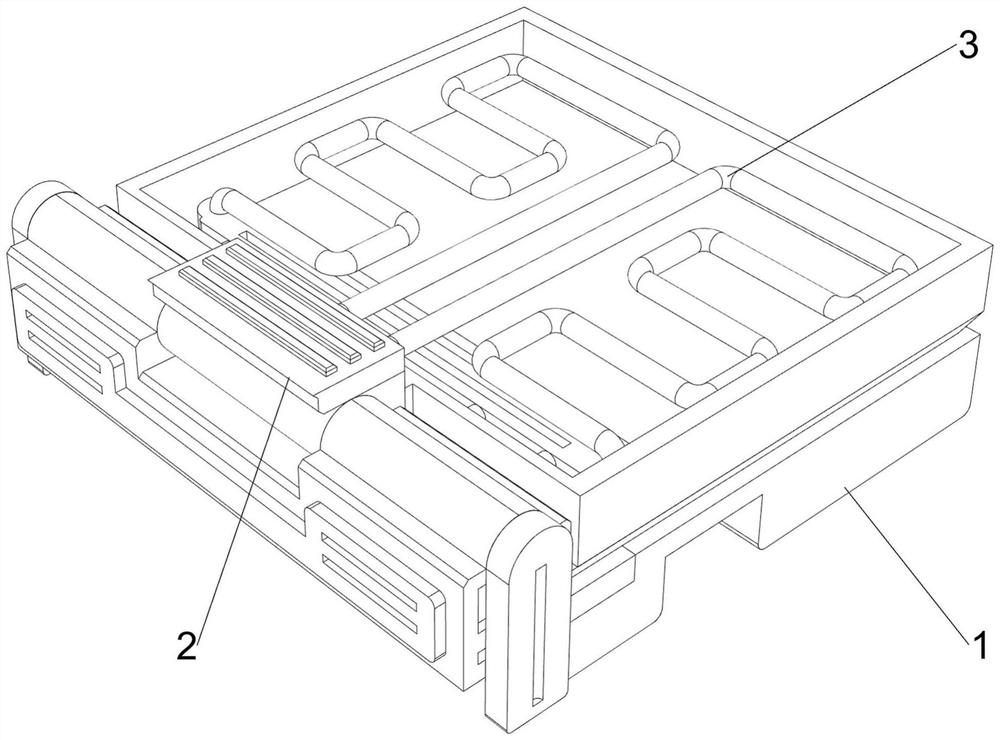

[0041] On the basis of Example 1, as figure 1 , figure 2 , Figure 8 and Figure 9 As shown, it also includes a protective mechanism 6 that can protect the heating tube 3. The protective mechanism 6 includes a connecting frame 61 and a sliding plate 62. The left and right sides of the rotating frame 2 are connected with a connecting frame 61 by bolts. The inner walls of the front and rear sides of the frame 61 are provided with two sliding grooves 63, and the two sliding grooves 63 are distributed up and down respectively. The left and right sides of the two sliding grooves 63 are also slidably connected with sliding plates 62 , and the upper and lower sliding plates 63 are respectively slidably connected. The sliding grooves 63 can guide the sliding plates 62 . The connection frame 61 is slidably connected, and the sliding plate 62 can protect the heating tube 3 .

[0042] When people need to heat the wall to speed up the solidification rate of the wall, first, people sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com