Hydrogen liquefaction and boil-off gas recondensation system based on low-temperature refrigerator

A low-temperature refrigerator, evaporative gas technology, applied in refrigeration and liquefaction, liquefaction, gas/liquid distribution and storage, etc., can solve the problems of inapplicability to small and medium-sized occasions, large scale of installations, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be pointed out that the following embodiments are intended to facilitate the understanding of the present invention, but do not have any limiting effect on it.

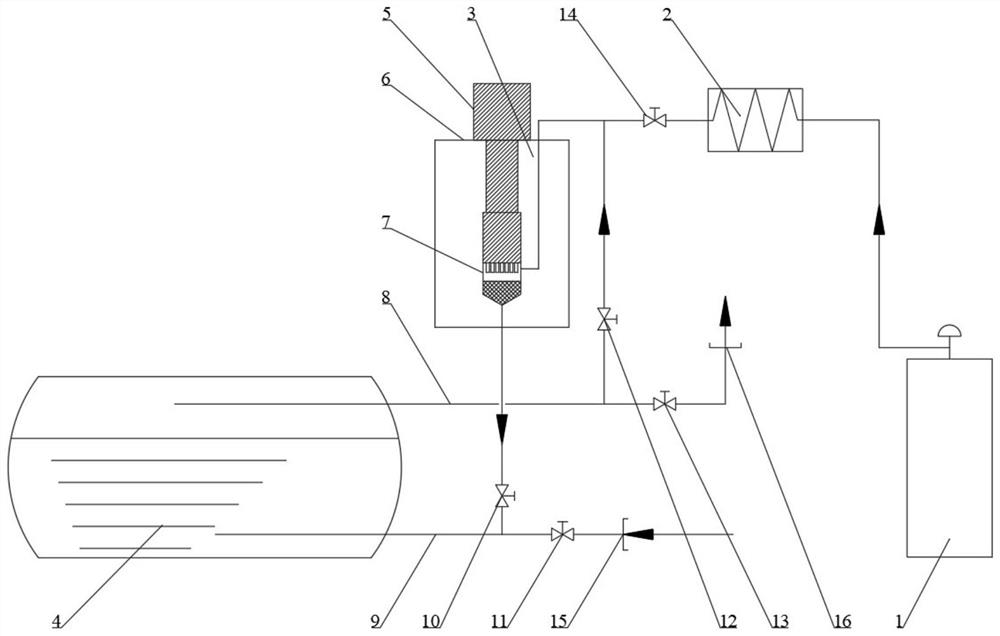

[0027] like figure 1 As shown, a system for hydrogen liquefaction and boil-off gas recondensation based on a cryogenic refrigerator includes a hydrogen cylinder 1 , a pre-cooling module 2 , a liquefaction module 3 and a liquid hydrogen storage tank 4 . The lower part of the liquid hydrogen storage tank 4 is provided with a liquid inlet pipe 9, the upper part is provided with an exhaust pipe 8, the filling port 15 of the liquid hydrogen storage tank 9 is provided with a No. 2 stop valve 11, and the exhaust port 16 of the exhaust pipe 8 is provided. There is a No. 4 stop valve 13 .

[0028] The hydrogen cylinder 1 is connected to the precooling module 2 and the liquefaction modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com