Efficient and comprehensive drying equipment for textile production

A drying equipment and textile technology, applied in the field of textile production, can solve the problems of uneven heating of towels, general drying effect, and affecting towel drying efficiency, and achieve the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

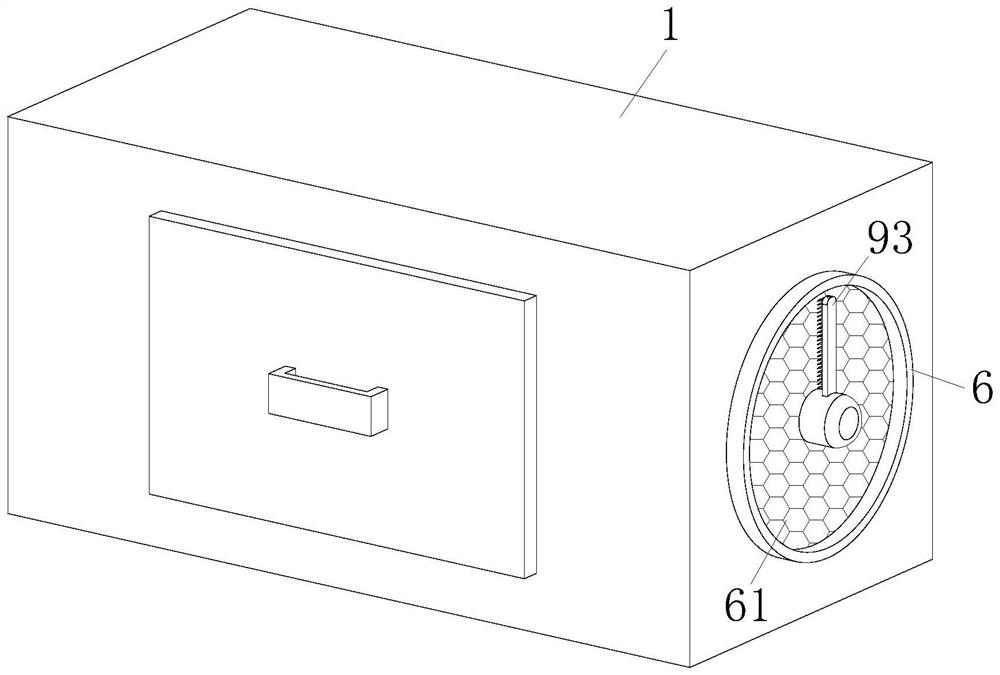

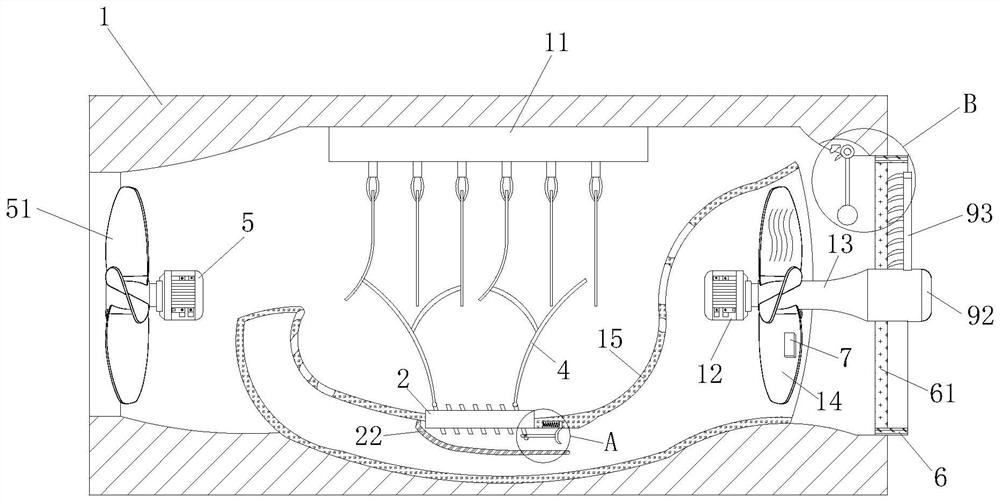

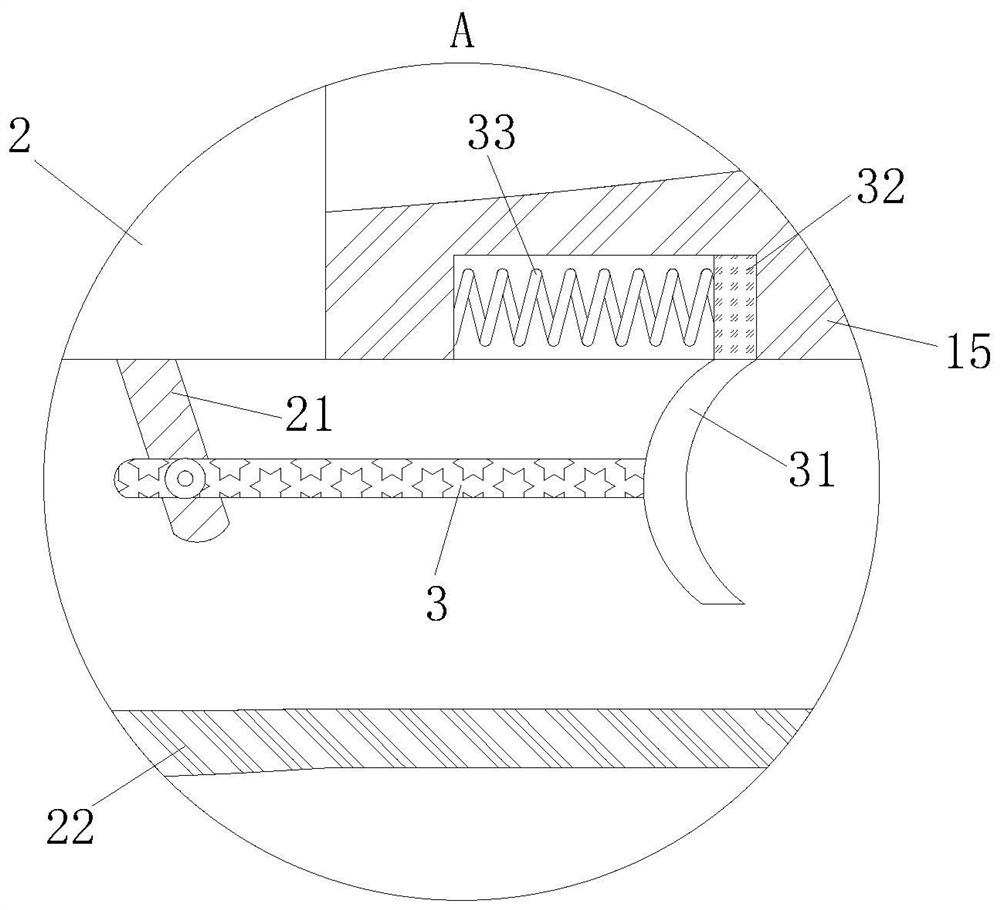

[0029] like Figure 1 to Figure 4 As shown, an efficient and comprehensive drying equipment for textile production according to the embodiment of the present invention includes a drying box 1; a towel fixing rack 11 is fixed inside the drying box 1; the towel fixing rack The bottom end of 11 is fixedly connected with multiple groups of racks, and the bottom ends of the towel fixing racks 11 are staggeredly fixed between the multiple groups of racks; the inside of the drying box 1 is fixedly connected with a No. 1 motor 12 ; the output of the No. 1 motor 12 is fixed. A connecting shaft 13 is fixedly connected to the end; a suction fan blade 14 is fixedly connected to the side wall of the connecting shaft 13; a heating wire is fixedly fixed to the side wall of the suction fan blade 14; The air duct 15; the shape of the air duct 15 is U-shaped, and the side walls of the air duct 15 are provided with multiple groups of holes; when drying the towels, multiple groups of towels are p...

Embodiment 2

[0039] like Figure 5 As shown, Comparative Example 1, wherein another embodiment of the present invention is: the inner side wall of the drying box 1 is fixed with a filter screen 94; The rotation of the output end of the No. 2 motor 5 drives the blowing fan blades 51 to extract the air inside the drying box 1, so that the air inside the drying box 1 flows, and the filter screen 94 blocks the dust and impurities outside the drying box 1 to avoid dust and impurities. Impurities fall on the blower blades 51 and affect the rotation effect of the blower blades 51 .

[0040] Working principle, when drying the towels, place multiple sets of towels inside the drying box 1, and use the racks at the bottom of the towel holder 11 to hold multiple towels crosswise, and the output end of the No. 1 motor 12 rotates to drive the The connecting shaft 13 rotates, and the connecting shaft 13 drives the rotation of the suction fan blades 14 fixed on the side walls, draws the air outside the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com