Oil sludge modeling symmetric mirror and efficient complex product oil sludge model processing method

A technology for complex products and clay models, applied in teaching models, instruments, installations, etc., can solve the problems of long processing cycle, high cost, and inability to quickly meet market demand for sludge models, saving manpower, saving costs, and shortening the development cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

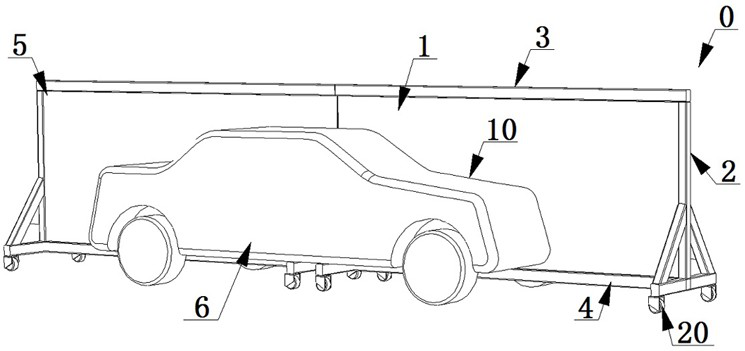

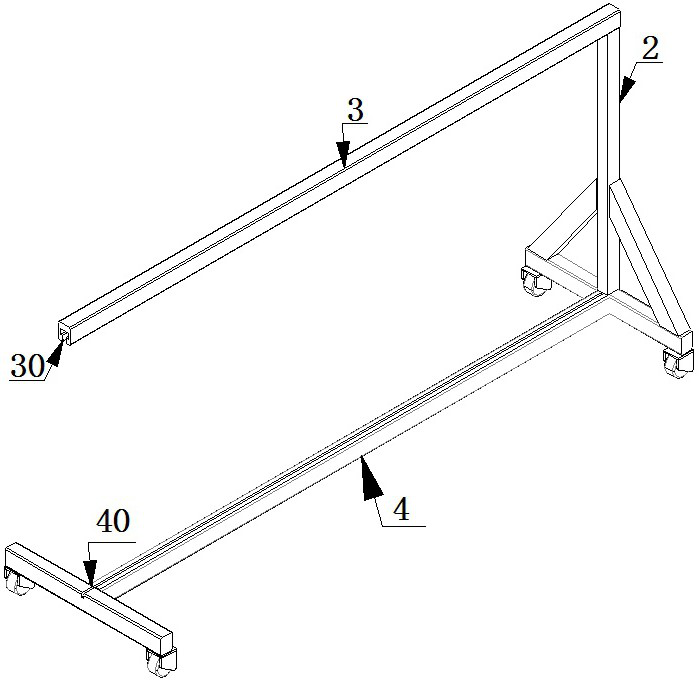

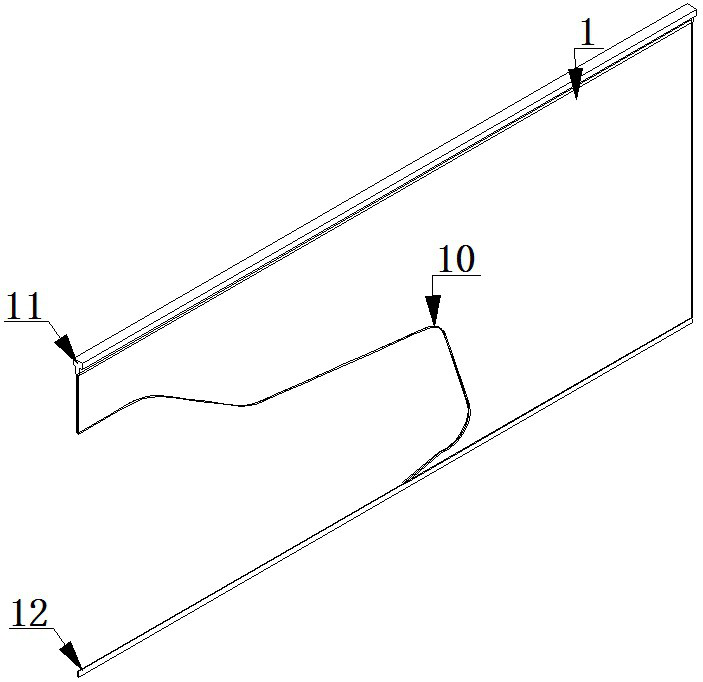

[0029] A clay-shaped symmetrical mirror, such as figure 1 An oil-mud-shaped symmetrical mirror, including a symmetrical mirror body 0, the symmetrical mirror body 0 includes a front symmetrical mirror 5, a rear symmetrical mirror 1, a mirror surface support frame and a universal caster 20, and the directional caster 20 is located in the symmetrical mirror body. 0 bottom, the upper end of the directional caster 20 is a mirror support frame, the mirror support frame includes a horizontal support rod 4, a vertical support rod 2, and an upper horizontal support rod 3, the bottom of the mirror support frame is a horizontal support rod 4, and the 4 ends of the horizontal support rod The part is a vertical support rod 2, the vertical support rod 2 is located at the upper end of the direction caster 20 at the same time, the upper end of the vertical support rod 2 is provided with an upper horizontal support rod 3, and the front symmetrical mirror 5 and the rear symmetrical mirror 2 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com