Automatic plate cutting device

A cutting device and plate technology, applied in auxiliary devices, welding/cutting auxiliary equipment, laser welding equipment, etc., can solve the problems of slow heating and reduced cutting efficiency at the cutting part of the plate, so as to improve cutting efficiency and heating efficiency. , Guarantee the effect of cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

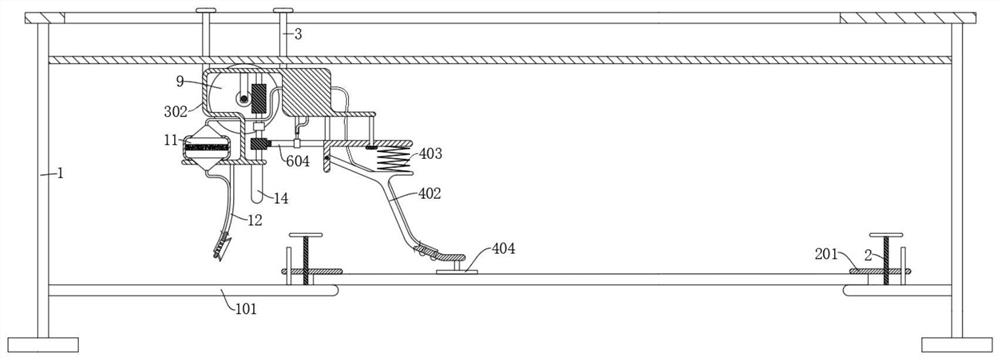

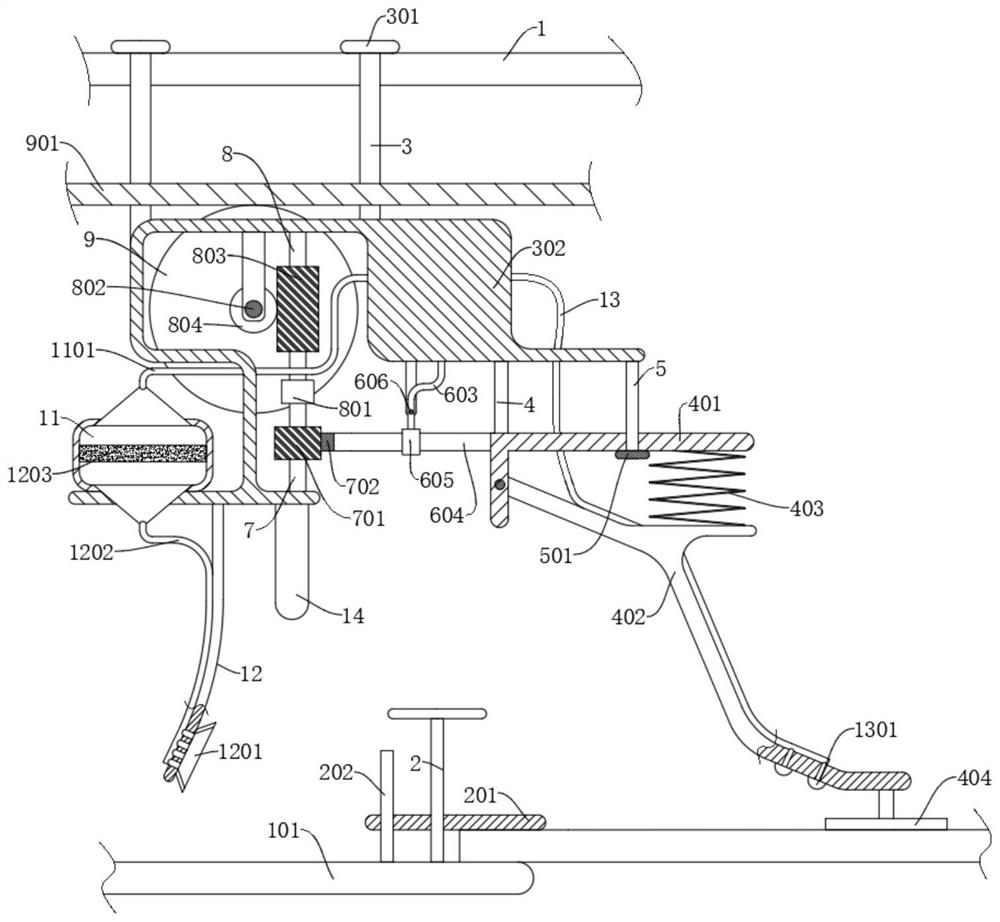

[0030] refer to Figure 1-7 , an automatic plate cutting device, including a fixed frame 1, a moving frame 302 horizontally sliding on the fixed frame 1, and also comprising: a laser cutter 14 fixed at the bottom of the moving frame 302, through the laser cutter 14, the plate is cut laser cutting.

[0031] The first fixed shaft 4 is fixedly connected to the bottom of the moving frame 302. The end of the first fixed shaft 4 away from the moving frame 302 is rotatably connected with a swinging plate 401. The bottom of the swinging plate 401 is connected with a spray head 1301. The nozzle of the spray head 1301 needs to be cut to align the plate. in front of.

[0032] The driving source arranged on the moving frame 302, when the driving source works, the swing plate 401 swings back and forth, and the moving frame 302 moves forward intermittently. The so-called intermittent movement is to move a certain distance, pause for a period of time, and then move forward again There is a...

Embodiment 2

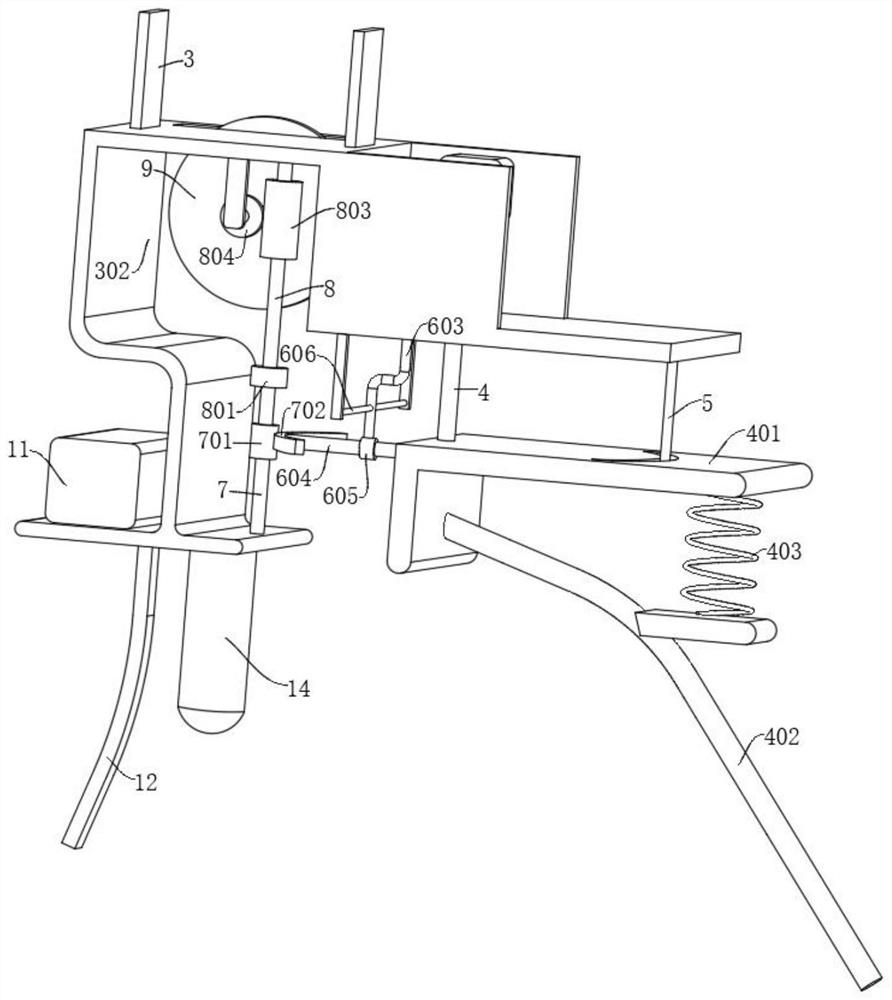

[0069] refer to Figure 1-7 , which is basically the same as Example 1. On the basis of Example 1, the overall technical solution is further optimized to improve the stability during cutting.

[0070] like figure 2 , 3 4. In order to improve the stability of the toggle rod 603 when moving, a second guide rod 606 fixed on the moving frame 302 is also included; the toggle rod 603 slides on the second guide rod 606 .

[0071] The toggle rod 603 is slid on the second guide rod 606, and the toggle rod 603 is deformed by force during the sliding process, which improves the stability of the work.

[0072] like figure 2 , 3 , 4, 5, in order to improve the stability of the swing plate 401 when it swings, it also includes a second fixed shaft 5 fixed at the bottom of the moving frame 302, the second fixed shaft 5 penetrates the swing plate 401, and the swing plate 401 is provided with a chute, The second fixed shaft 5 slides in the chute.

[0073] One end of the second fixing sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com