Detachable cast-in-place concrete reserved hole mold

A concrete and hole-reserved technology, applied in the fields of formwork/formwork/work frame, on-site preparation of building components, connection of formwork/formwork/work frame, etc. The problem of high adhesion strength, etc., can improve the utilization rate and construction efficiency, facilitate control and quick disassembly, and facilitate recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

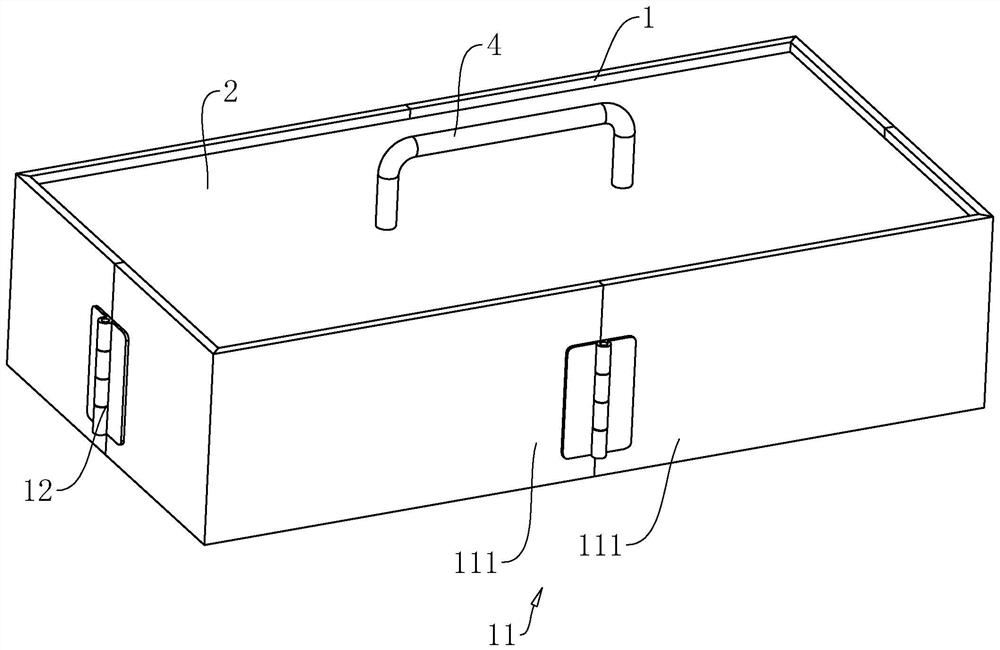

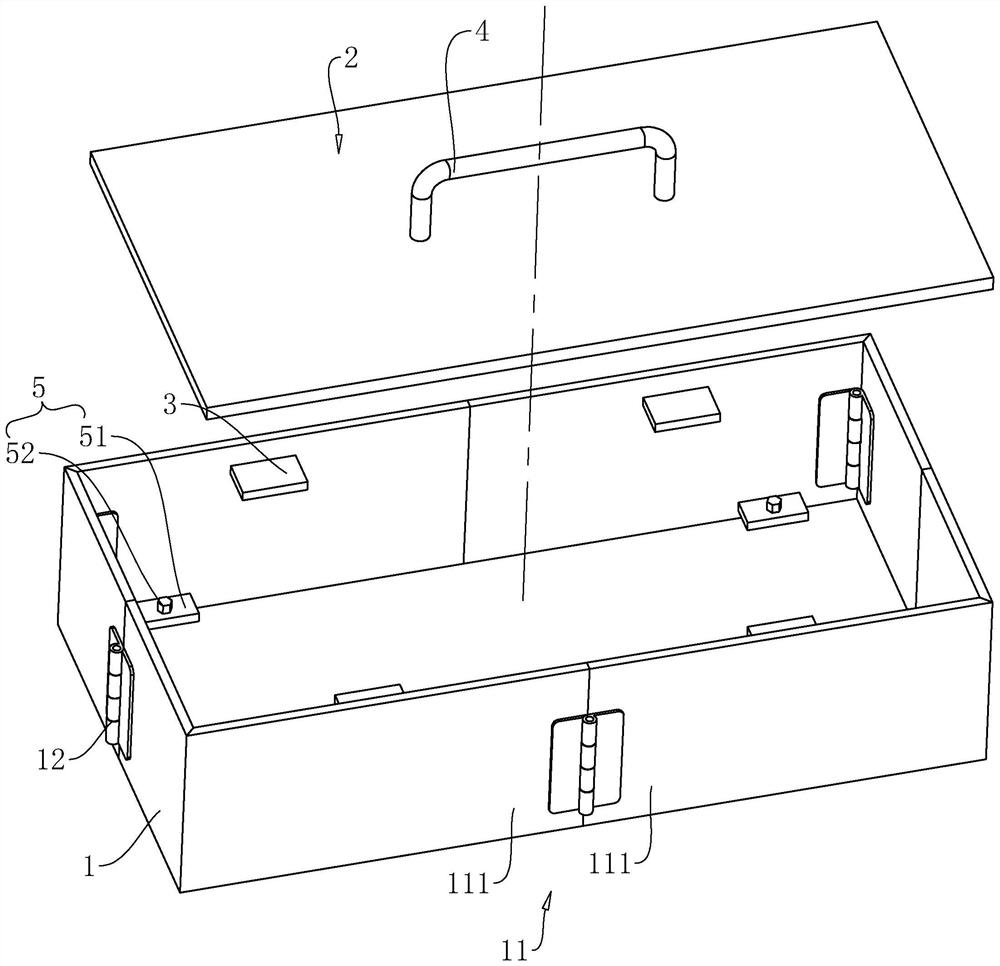

[0047] refer to figure 1 and figure 2 , the reserved hole mold includes an isolation box 1 that is hollow inside, and the isolation box 1 is a cuboid with top and bottom openings; the top opening of the isolation box 1 is provided with a top plate 2, and the side of the top plate 2 close to the isolation box 1 is opened along its circumferential direction There is a chamfer, and the chamfer is used for guiding and positioning when the top plate 2 is inserted into the opening at the upper end of the isolation box 1, so that the construction personnel can easily insert the top plate 2 into the isolation box 1. The inner side wall of the isolation box 1 is fixed with a plurality of mounting plates 3 along its circumferential direction. The multiple mounting plates 3 are located at the top opening of the isolation box 1 and are on the same horizontal plane. A handle 4 is also fixed above the top plate 2, and the handle 4 is used to facilitate the construction personnel to move t...

Embodiment 2

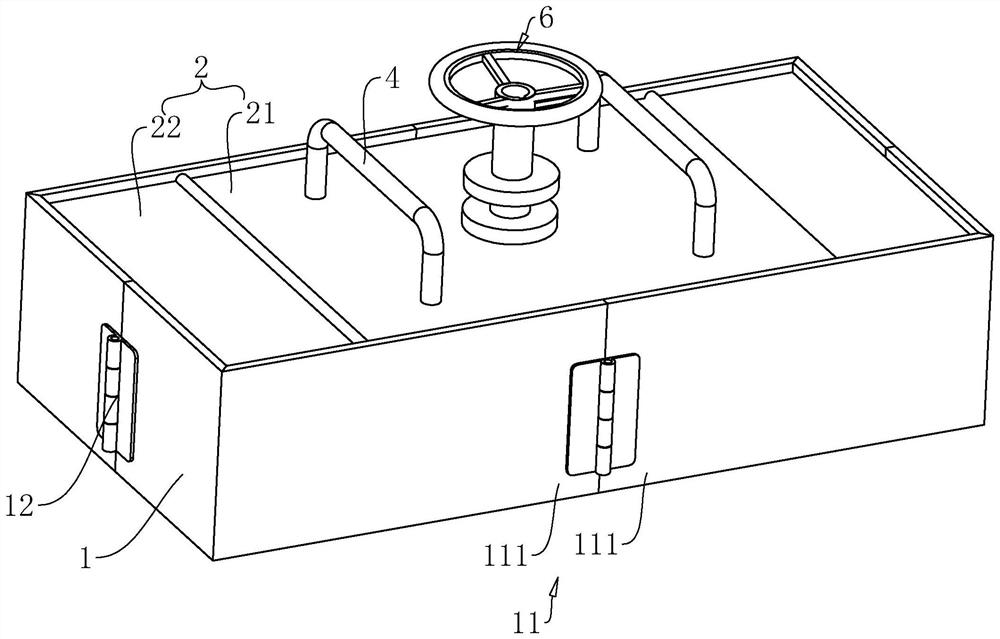

[0052] refer to figure 2 and image 3 , the difference from Embodiment 1 is that the top plate 2 includes a main support cover 21 and branch covers 22 hinged on both sides of the main support cover 21. The branch covers 22 are used to open the four end corners of the top of the isolation box 1, thereby facilitating the The construction personnel manipulate the connection assembly 5 to realize the installation and disassembly of the isolation box 1 and the floor slab. A synchronous shrinking mechanism 6 is also arranged between the isolation box 1 and the top plate 2. The synchronous shrinking mechanism 6 is used to drive the four side plates 11 to sag inward at the same time, so that the two support plates 111 in each side plate 11 are close to each other. Move to the inside of the side isolation box 1 .

[0053] refer to Figure 4 and Figure 5 , the synchronous retraction mechanism 6 includes a rotating shaft 61 rotatably connected to the top plate 2, the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com