Moving coil with composite guide structure for electric vibration table

An electric vibrating table and composite guiding technology, which is used in the testing of machine/structural components, vibration testing, measuring devices, etc., can solve the problems of uneven distribution of lubricating oil film, affecting waveforms, and interference of moving coils, reducing surface hardness, The effect of reducing bearing mass and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

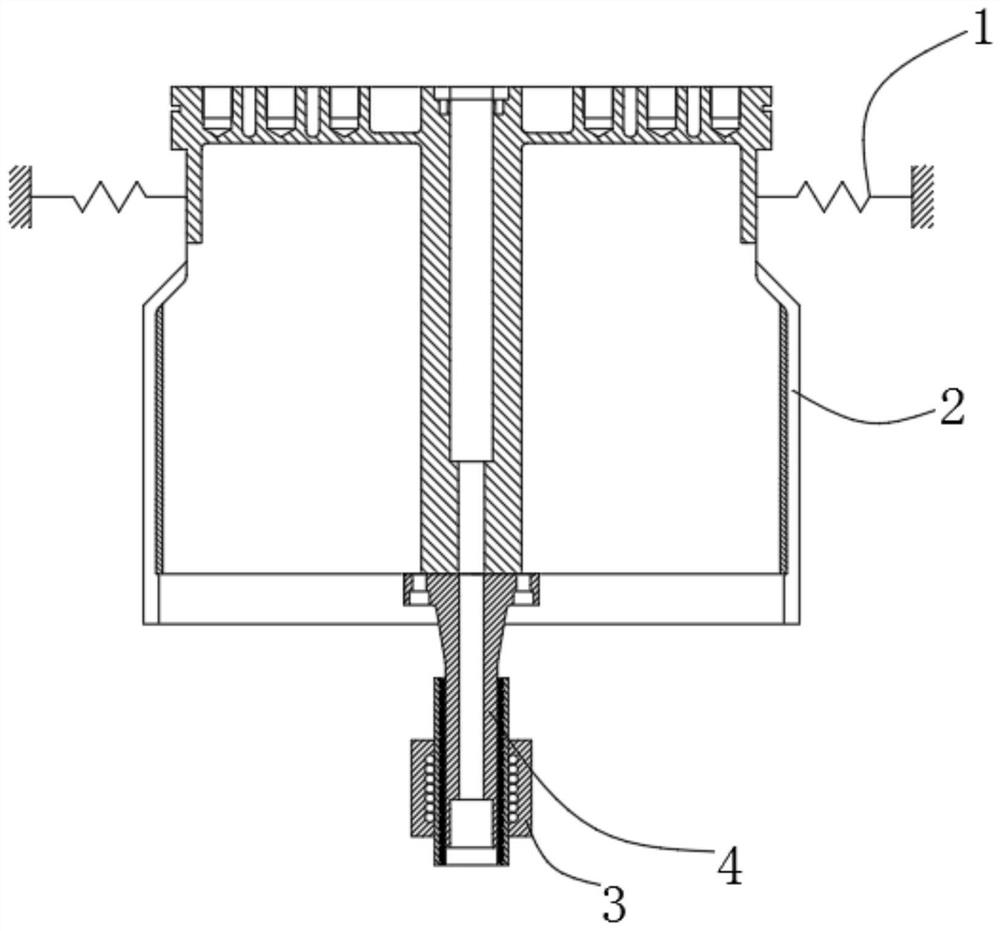

[0021] Example one, by Figure 1-3 Given, the present invention provides a moving ring with a composite guide structure for an electrodynamic vibration table, comprising a leaf spring 1, a moving ring 2, a bearing 3 and a composite guide shaft mechanism 4, the upper circumferential outer ring of the moving ring 2 is Four leaf springs 1 are evenly distributed, a composite guide shaft mechanism 4 is installed on the bottom of the moving ring 2, and a bearing 3 is installed on the outer side of the composite guide shaft mechanism 4;

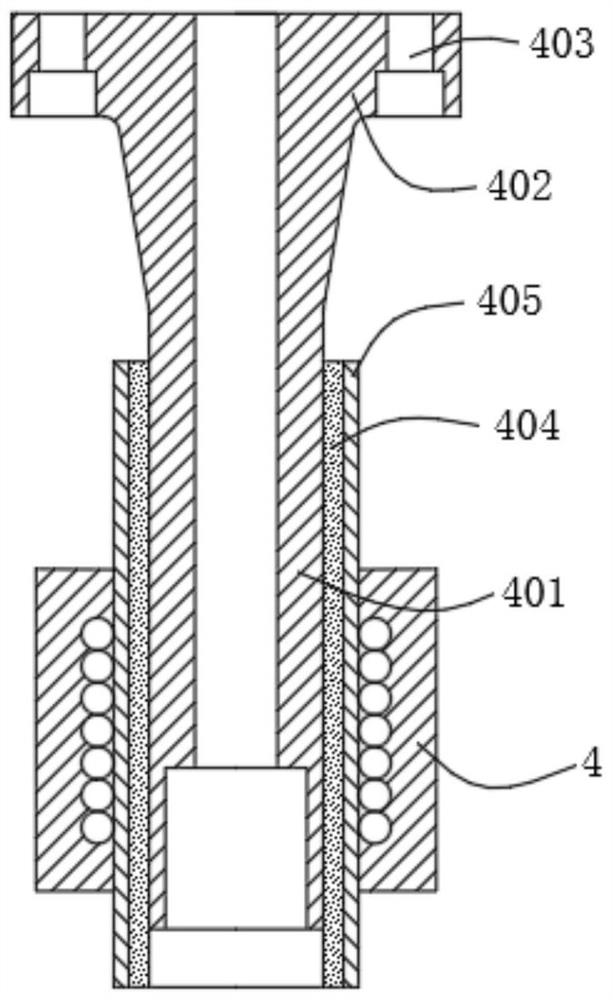

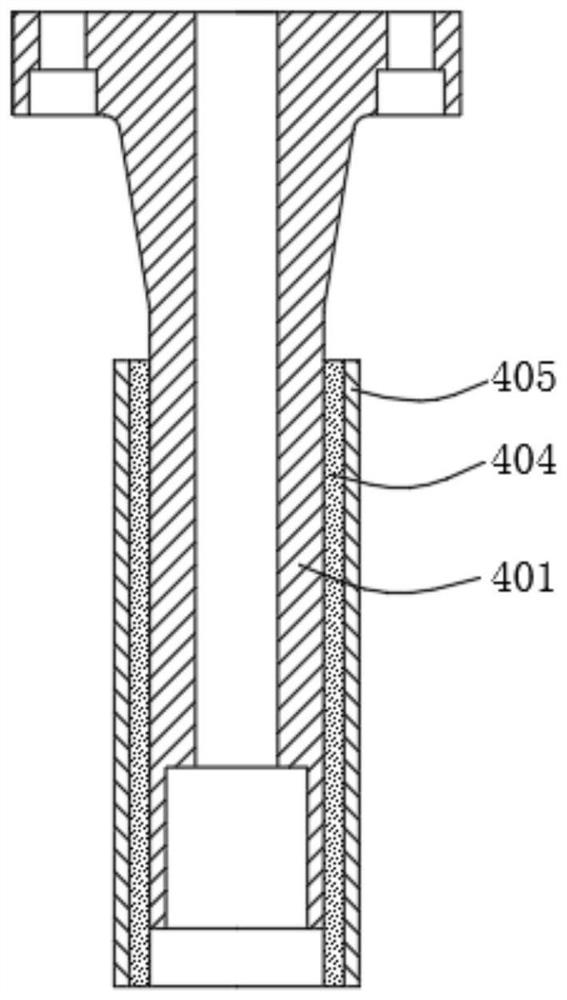

[0022] The composite guide shaft mechanism 4 includes a shaft core 401, a mounting plate 402, a mounting hole 403, a rubber interlayer 404 and a sleeve 405. The top end of the shaft core 401 is provided with a mounting plate 402, and the edge of the mounting plate 402 is provided with several mounting holes 403 , the outer side of the shaft core 401 is provided with a rubber interlayer 404, and the outer side of the rubber interlayer 404 is sleeved ...

Embodiment 2

[0024] In the first embodiment, the connection between the mounting plate 402 and the moving coil 2 is inconvenient. figure 1 , as another preferred embodiment, the difference from the first embodiment is that the mounting plate 402 is connected with the moving coil 2 through bolts, which is convenient for the connection and use of the mounting plate 402 and the moving coil 2 .

Embodiment 3

[0026] In the first embodiment, the rubber interlayer 404 is inconvenient to use, refer to Figure 1-3 , as another preferred embodiment, the difference from the first embodiment is that the thickness of the rubber interlayer 404 is 3 mm, which is convenient for the use of the rubber interlayer 404 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com