Numerical control machining tool path optimization method based on asymmetric PH curve

A trajectory optimization, asymmetric technology, applied in digital control, comprehensive factory control, electrical program control, etc., can solve problems such as a large increase in data volume, and achieve the effect of increasing feed rate and improving continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

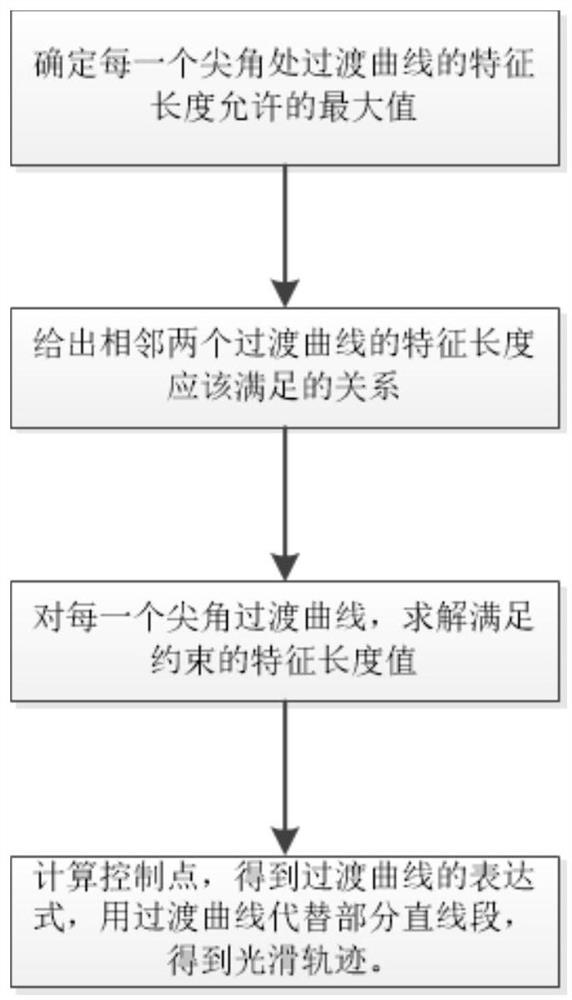

Method used

Image

Examples

Embodiment 1

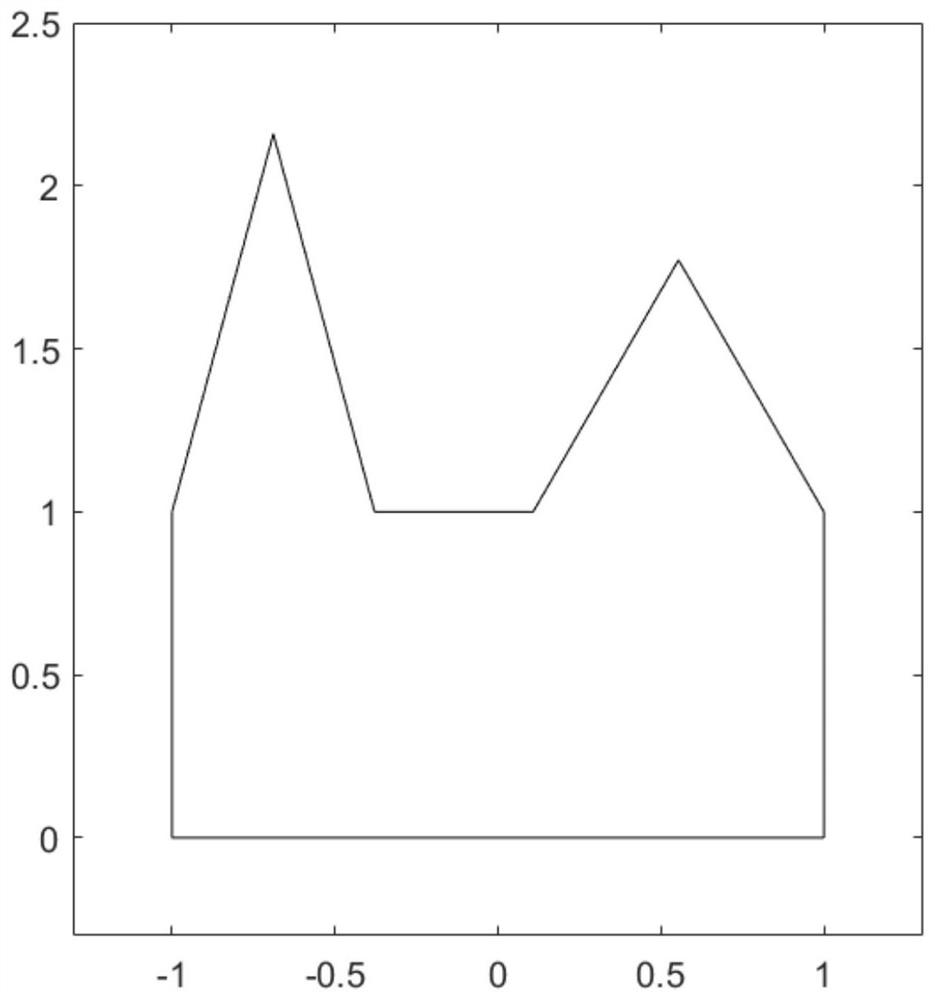

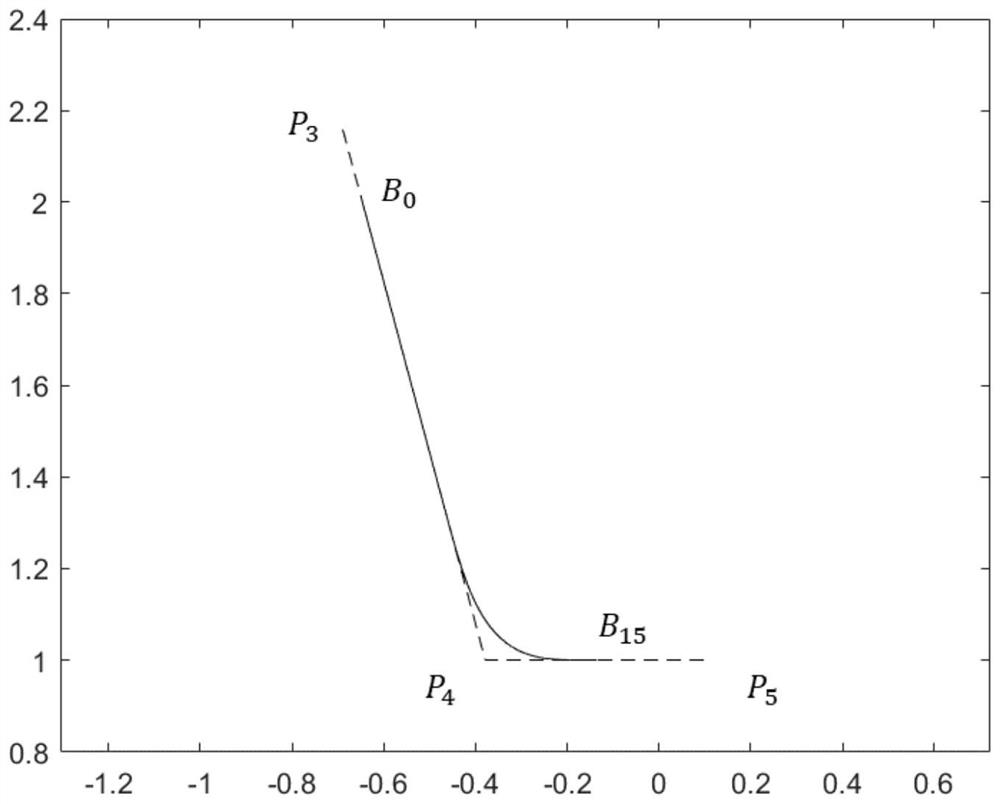

[0088] Below as figure 2 A G01 trajectory is shown as an example to implement the steps of the present invention. The three-dimensional coordinates of the tool position point of the tool path path are shown in Table 1:

[0089] Table 1 The three-dimensional coordinates of the tool position point of the G01 path

[0090]

[0091] In step 1, the maximum allowable contour error is given as ε=0.08, and P is calculated according to formula (1). i Angle θ of sharp corners at (i=1,...,8) i , get θ 1 =1.5708, θ 2 =0.2618, θ 3 = 2.6180, θ 4 =1.3090, θ 5 =1.0471, θ 6 = 2.0943, θ 7 = 0.5236 and θ 8 =1.5708. Substitute the angle value into formula (2) to calculate the upper limit l of the characteristic length of the transition curve at the sharp corner ε,i , get l ε,1 =0.0428, l ε,2 =0.2971, l ε,3 =0.0135, l ε,4 =0.0542, l ε,5 =0.0704, l ε,6 =0.0266, l ε,7 = 0.1471 and l ε,8 = 0.0428.

[0092] In step 2, the length of each straight line segment of the G01 traject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com