Deep learning wafer welding spot detection method based on improved YOLOV5

A technology of solder joint detection and deep learning, applied in the field of target detection, to improve the accuracy of target detection, improve the ability of network feature extraction, and reduce the effect of information loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

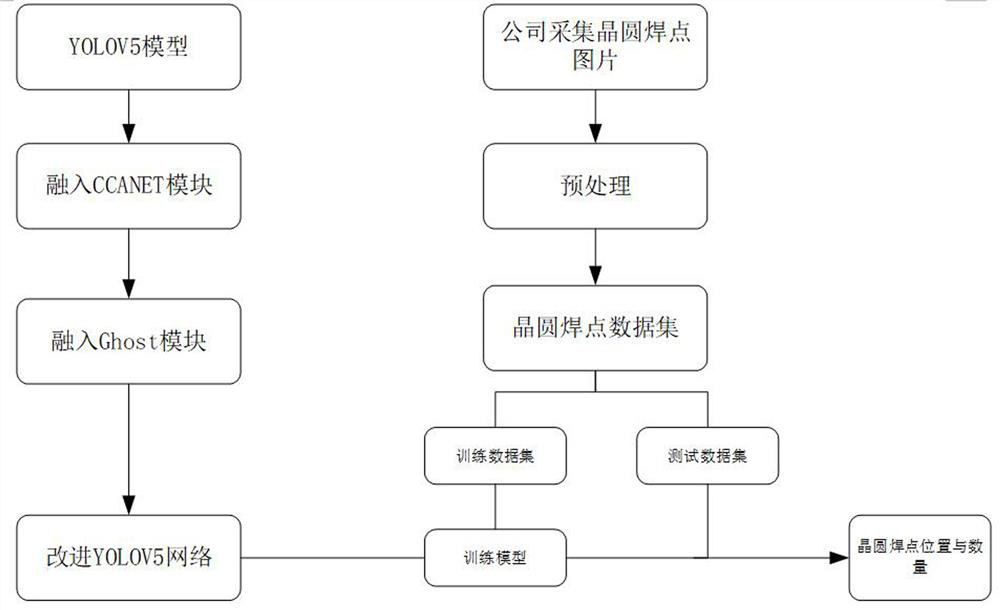

[0053] refer to figure 1 , a deep learning wafer solder joint detection method based on improved YOLOV5, comprising the following steps:

[0054] 1) Making a data set of wafer solder joints: collect images of wafer solder joints, preprocess the collected wafer solder joint images to improve the number of samples and picture quality of the data set, and then mark the data set to meet the needs of The aligned solder joints and the solder joints that do not need to be aligned are marked with rectangles. The solder joints that need to be aligned are named Rig holes, and the solder joints that do not need to be aligned are named Wro holes, and finally a 1464 wafer solder joint images are produced. Wafer solder joint data set, and divide the data set into training set and validation set with a ratio of 9:1;

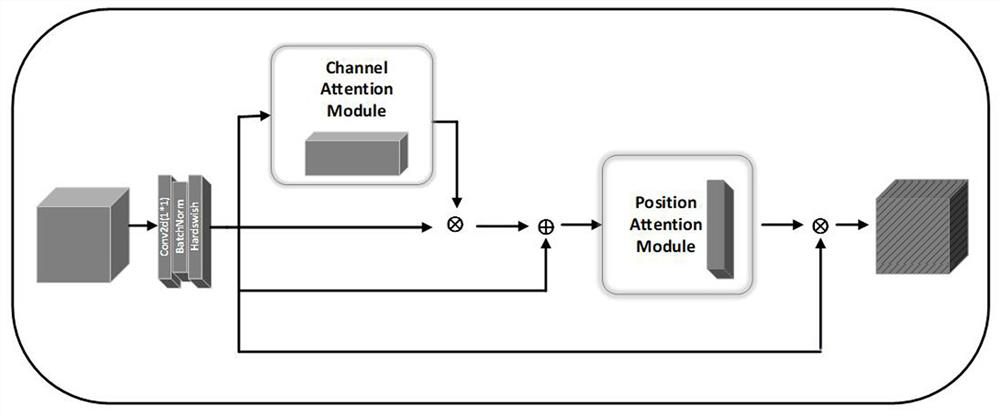

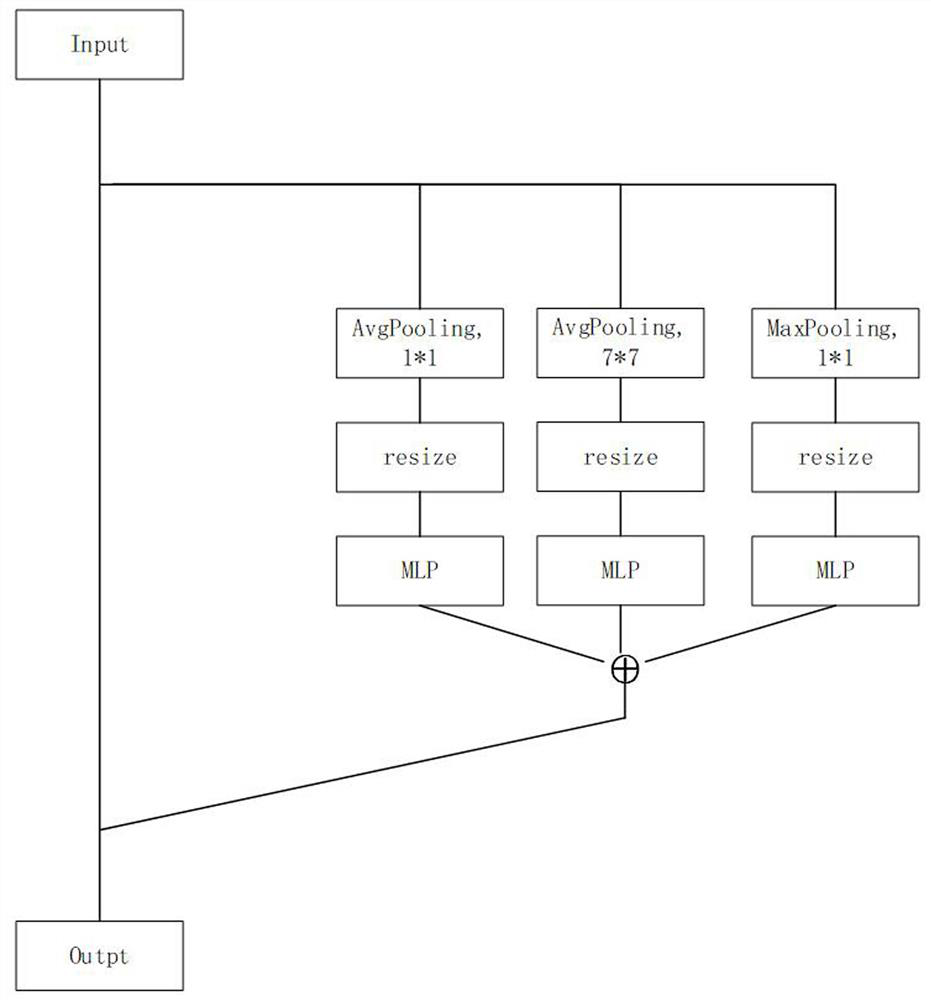

[0055] 2) Construct the attention mechanism module CCANET: The attention mechanism module CCANET is as follows figure 2 shown, including:

[0056] 2.1) Firstly, a filter mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com