Anti-interruption feeding system for dry denitration conveying equipment

A technology of conveying equipment and feeding system, which is applied in the field of anti-interruption feeding system for dry denitrification conveying equipment, which can solve the problems of affecting material conveying, accumulation on the pipe wall, and affecting the normal progress of chemical reactions, etc., to expand the distribution area Domain, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

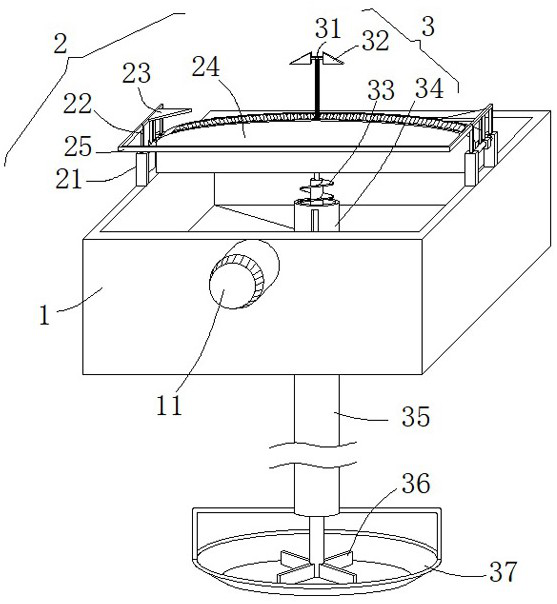

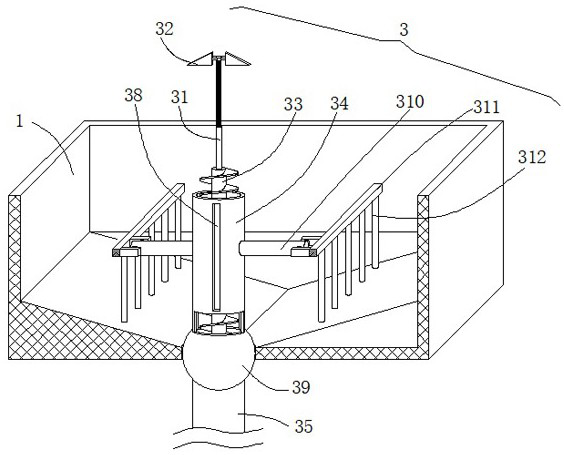

[0033] see figure 1 , figure 2 , Image 6 , Figure 7 and Figure 9 , This embodiment provides an anti-interruption feeding system for dry denitrification conveying equipment, including a hopper 1, a spreading mechanism 3 for introducing the materials in the hopper 1 into the furnace, and a guiding mechanism 2 for evenly swinging and spreading the material by the auxiliary spreading mechanism 3, The hopper 1 is used to hold the materials to be exported. The material in the hopper 1 is introduced into the furnace by the spreading mechanism 3. The guide mechanism 2 assists the spreading mechanism 3 to evenly sway and spread the material, and at the same time, it can also realize the expansion of the distribution area of the material. Improve the chemical reaction efficiency and improve the denitration efficiency.

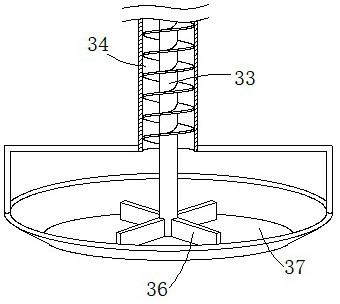

[0034]The material spreading mechanism 3 includes a first material guide pipe 34 and a second material guide pipe 35. A hollow spherical block 39 is fixedly co...

Embodiment 2

[0043] see figure 1 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9 , made further improvements on the basis of Example 1:

[0044] In order to facilitate the adjustment of the position of the guide seat 24 forward and backward on the hopper 1, the guide mechanism 2 includes two sets of support blocks 21, the two support blocks 21 are a set, and the two sets of support blocks 21 are respectively arranged on both sides of the upper end of the hopper 1, and the same A pin shaft 29 is rotatably provided between the two supporting blocks 21 of the group. Both ends of the guide seat 24 are fixedly provided with a sliding block 26 slidably inserted with the pin shaft 29. 21 on the pin 29.

[0045] In addition, by sliding the slider 26 along the outer wall of the pin shaft 29 to adjust the position, the guide seat 24 can be adjusted back and forth. Alternately engage with the tooth slots 313 of the rocking rod 31 to ensure that when the rocking rod 31 swings left ...

Embodiment 3

[0050] see figure 1 , figure 2 and Figure 4 , made further improvements on the basis of Example 2:

[0051] In order to realize the automatic and even material spreading operation, the outer wall of the hopper 1 is provided with a transmission member 11 capable of swinging the rocking rod 31 back and forth in the fan-shaped guide hole, and the transmission member 11 is used to drive the rocking rod 31 to swing back and forth in the fan-shaped guide hole, so as to achieve uniform continuous swing. Effective spreading operation.

[0052] The transmission member 11 is preferably a motor, and the power shaft of the motor rotates and extends to the interior of the hopper 1, and is fixedly connected with a Z-shaped lever 12, the other end of the Z-shaped lever 12 is fixed with a plug-in rod 13, and the first material guide tube 34 The outer wall is provided with axially distributed guide grooves 38, the plug-in rod 13 is slidably connected with the guide groove 38, the motor pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com