New energy automobile air return grille and manufacturing method thereof

A technology of new energy vehicles and manufacturing methods, applied in the direction of manufacturing tools, vehicle parts, transportation and packaging, etc., can solve the problems of tailor welding trouble, affect manufacturing efficiency, and cannot realize full automation, and achieve the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0089] like Figure 1 to Figure 20 As shown, this application provides:

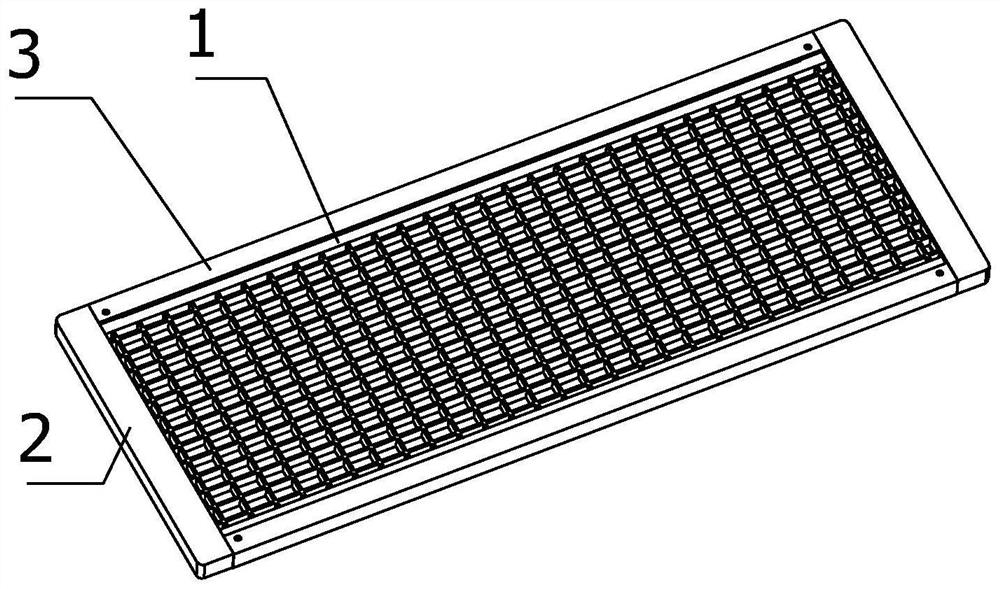

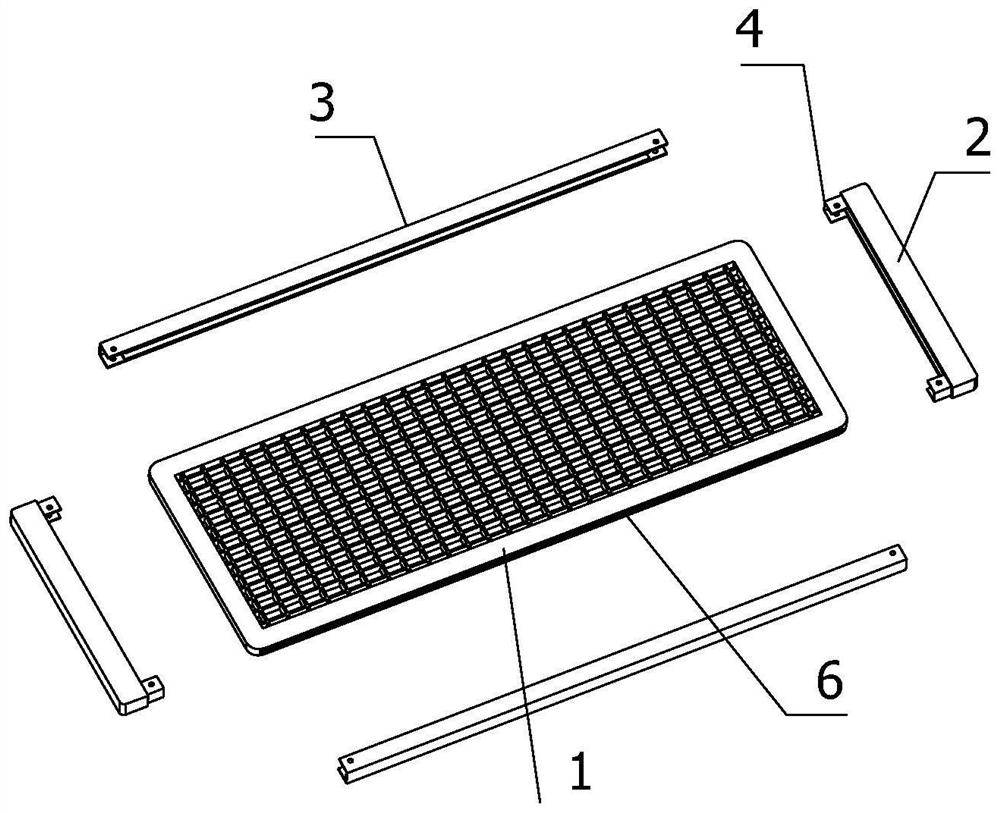

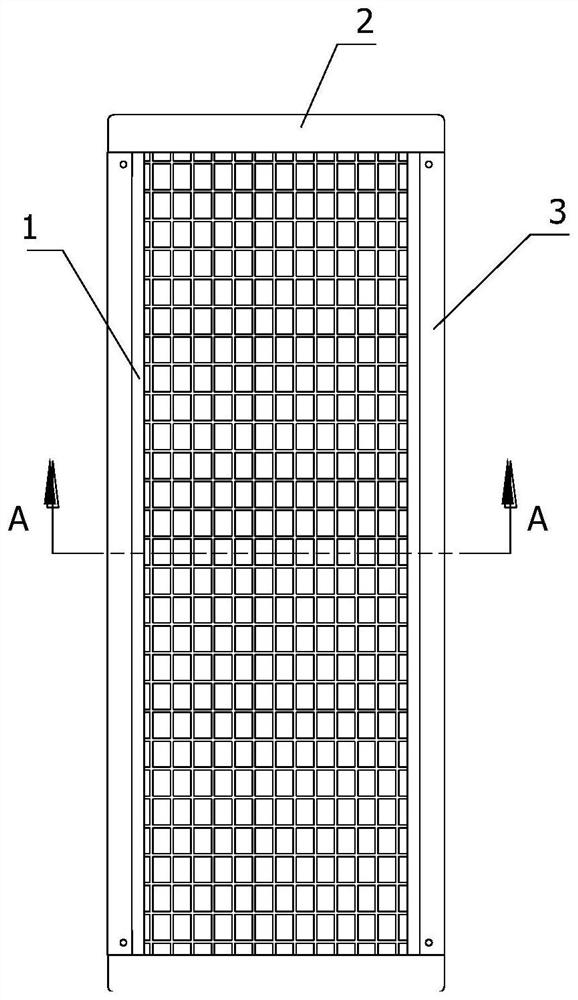

[0090] A new energy vehicle air return grille, comprising a grille plate 1, two short sidings 2 and two long sidings 3, the two long sidings 3 are relatively arranged on the two long sides of the grille plate 1, The two short side materials 2 are oppositely arranged at the two short sides of the grid plate 1, and the grid plate 1 is arranged between the two long side materials 3 and the two short side materials 2;

[0091] Both ends of the long sapwood 3 are respectively provided with first screw holes;

[0092] Both ends of the short side material 2 are respectively provided with a connecting piece 4 that can be inserted into one end of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com