Energy device exchange system for hydrogen energy moped

A technology of exchange system and hydrogen energy, applied in vehicle parts, transportation hydrogen technology, bicycle accessories, etc., can solve problems such as inconvenient exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

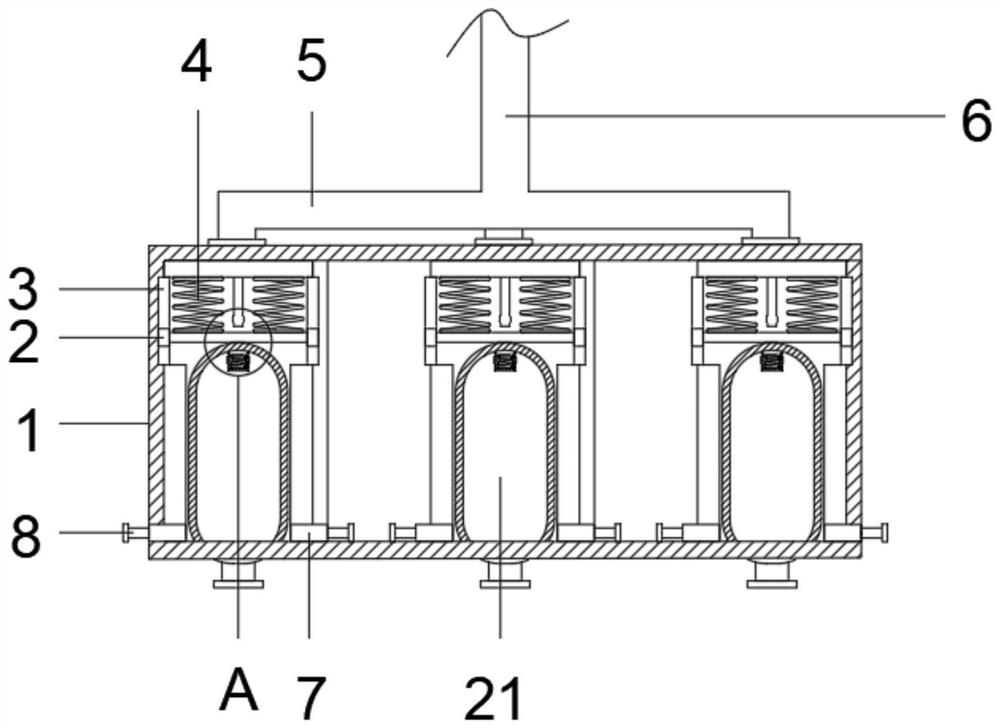

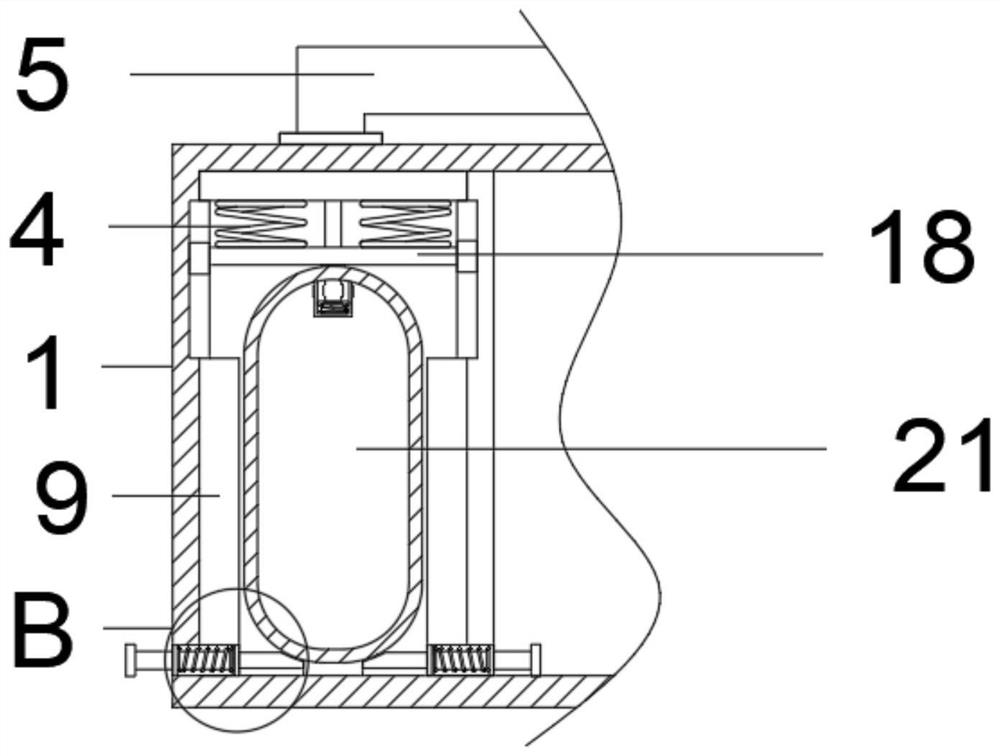

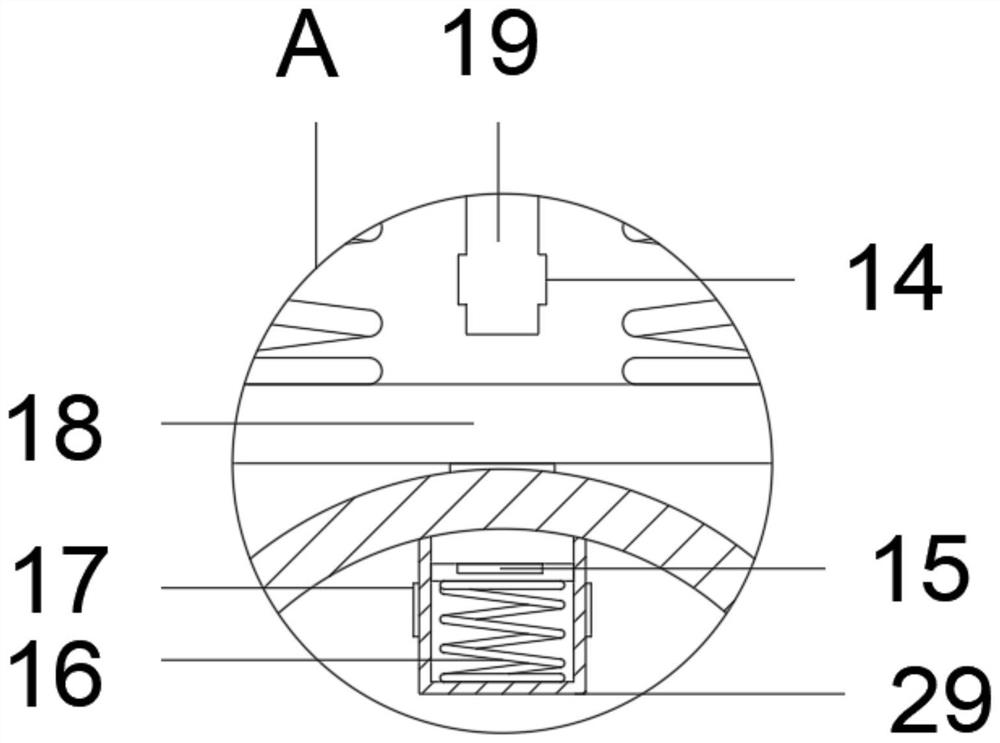

[0032] like Figure 1-6 As shown, the embodiment of the present invention provides an energy device exchange system for a hydrogen energy power-assisted vehicle, including an exchange device main body 1, and a first ventilation block 23, a second ventilation block 24, and a first ventilation block 23, a second ventilation block 24, and a first ventilation block 23, a second ventilation block 24, and a first ventilation block 23, a second ventilation block 24, and a first ventilation block 23 are fixedly connected to the top of the exchange device main body 1, respectively. Three ventilation blocks 28 , the first ventilation block 23 , the second ventilation block 24 and the third ventilation block 28 are fixedly connected with a chute 3 on both sides at one end of the inner side, and a slider 2 is slidably fitted inside the chute 3 . , through the sliding cooperation of the sliding slot 3 and the slider 2 to increase the stability, a support plate 18 is fixedly connected betwee...

Embodiment 2

[0035] By setting this structure, the sliding block 2 and the sliding groove 3, the sliding block 2 and the sliding groove 3 realize the stable effect of the support plate 18 during the elastic support of the first spring 4 to push and recover, and strengthen the movement of the support plate 18. At the same time, the sliding block 2 and the chute 3 are beneficial to the pushing of the hydrogen energy gas tank 21, reducing the friction force and reducing the pushing force.

[0036] The elastic support is achieved by the first spring 4 , which facilitates the insertion and pushes one end of the hydrogen energy gas tank 21 to push out of the fourth opening 27 for easy removal.

[0037] The replacement of multiple hydrogen energy gas tanks 21 is realized through the first ventilation block 23, the second ventilation block 24 and the third ventilation block 28, which is convenient to operate and has higher efficiency during use, and the cost of the main body 1 of the exchange device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com