Black shading conductive cloth adhesive tape and preparation method thereof

A black shading layer, conductive cloth technology, applied in photovoltaic power generation, adhesives, inks, etc., can solve the problem of conductive shading tapes easily warped, improve service life and product yield, solve warping, adhesion performance and other problems. Excellent anti-lifting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

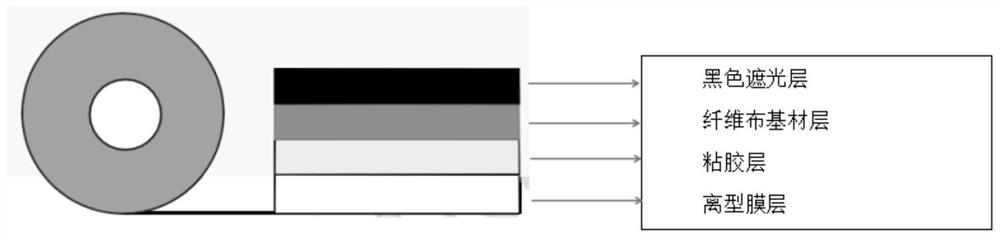

[0039] This embodiment provides a black light-shielding conductive cloth tape, refer to figure 1 , along the thickness direction of the tape, it includes a release film layer, a conductive adhesive layer, a conductive fiber cloth layer and a black light-shielding layer. The adhesive strength (peeling force) of the conductive adhesive layer is 1200gf / 25mm, and the thickness of the conductive fiber cloth layer is 0.05mm. The concrete preparation method of this tape is as follows:

[0040] (1) In this embodiment, an ordinary silver-gray conductive fiber cloth is selected as the base material, and the surface of the silver-gray conductive fiber cloth is subjected to waterproof and anti-penetration treatment to obtain a conductive fiber cloth layer.

[0041](2) The surface of the conductive fiber cloth layer after surface treatment is coated with black ink again. The components of the black ink include 70% by weight of polyamideimide resin, 15% by weight of solvent toluene, 10% of...

Embodiment 2

[0050] This embodiment provides a black light-shielding conductive cloth tape, refer to figure 1 , along the thickness direction of the tape, it includes a release film layer, a conductive adhesive layer, a conductive fiber cloth layer and a black light-shielding layer. The black light-shielding conductive cloth tape of the present embodiment and the preparation method thereof are basically the same as those in Embodiment 1, and the main differences are:

[0051] 1) The adhesive strength of the conductive adhesive layer is 1700gf / 25mm, and the thickness of the conductive fiber cloth layer is 0.035mm.

[0052] In this example, the tape was placed in a normal temperature test for 24 hours, and a high and low temperature test of -40°C to 90°C for 7 days, and the test results were recorded in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel force | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com