Pressure-bearing building and assembly method thereof

A technology of construction and pressure-bearing plates, which is applied in the direction of construction, building components, and residential buildings. It can solve the problems of unable to realize large-area pressure rooms, cannot be transported and transferred, and unfavorable for people to live in. It achieves convenient transportation and simplifies the assembly process. , to avoid the effect of rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention may be implemented in many different ways as defined and covered by the claims.

[0041] In plateaus and other environments with thin air and low air pressure, staff from plain areas living in ordinary airtight rooms 2 often suffer from altitude sickness and make it difficult to sleep. Therefore, in the plateau area, it is necessary to change the indoor air pressure of the house to form the same indoor environment as the plain area. The study of a prefabricated steel structure house that can bear pressure and transfer the site is a new topic of prefabricated buildings in the plateau.

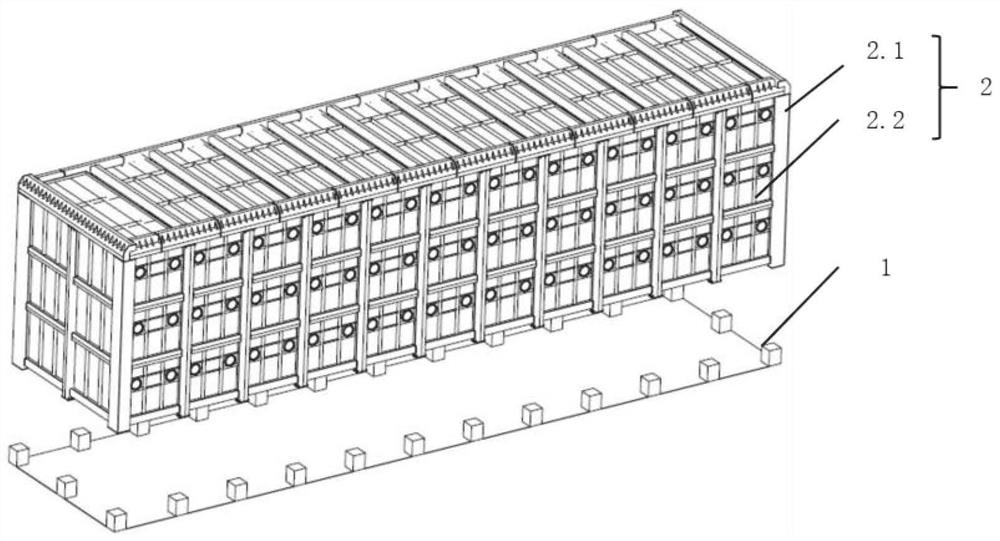

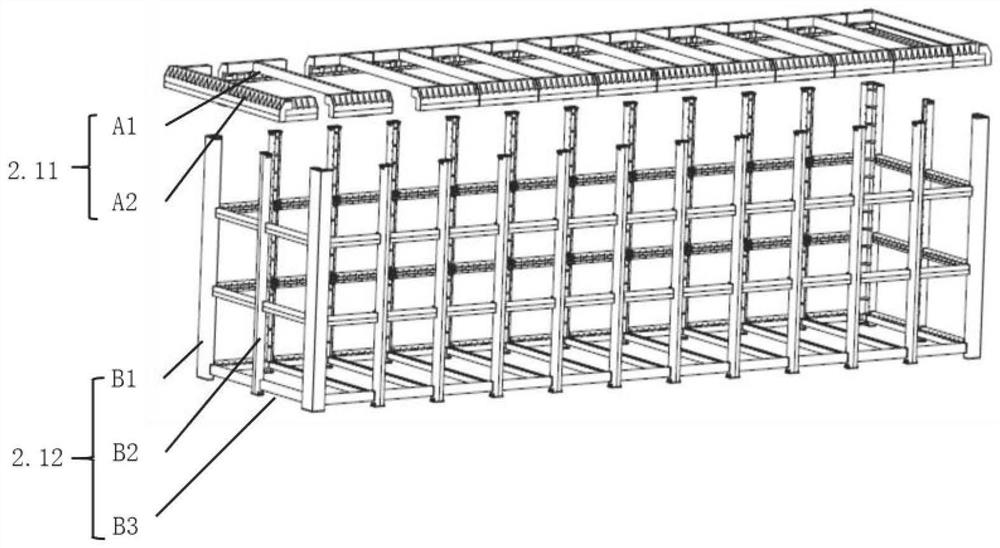

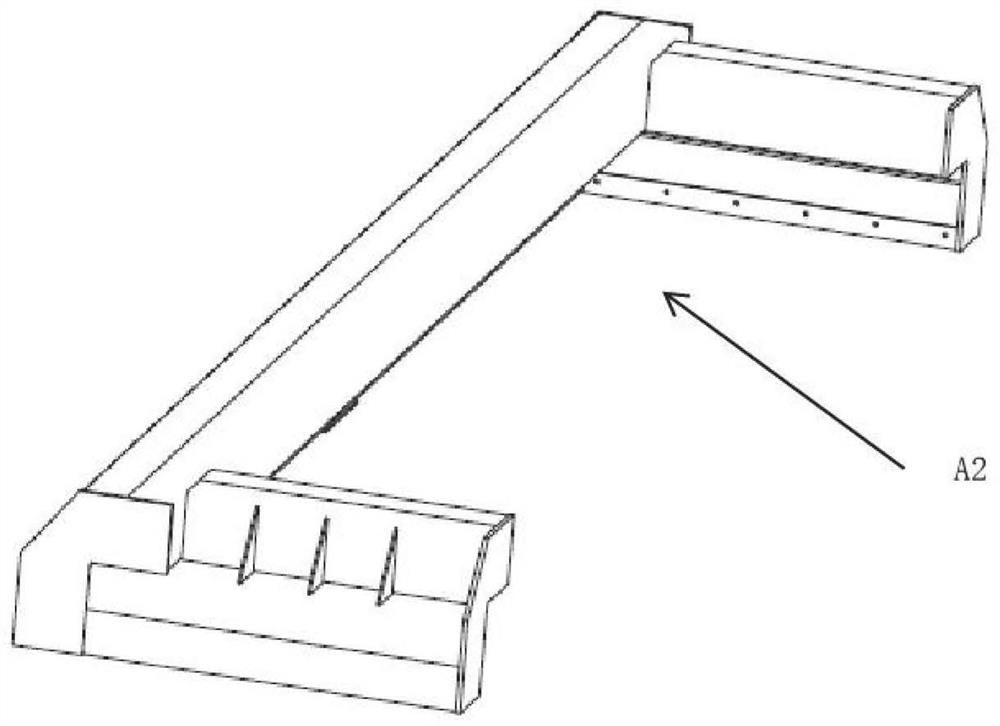

[0042] In order to solve the above problems, this embodiment realizes a pressure-bearing building, such as figure 1 As shown, the pressure-bearing building includes a foundation 1 and an airtight housing body 2 assembled on the foundation 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com