Accurate grouting and water plugging method suitable for silty-fine sand and silty-clay stratums

A technology of silt and fine sand and grouting, which is used in earth-moving drilling, underground chambers, functional valve types, etc. Guaranteed accuracy and improved grouting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

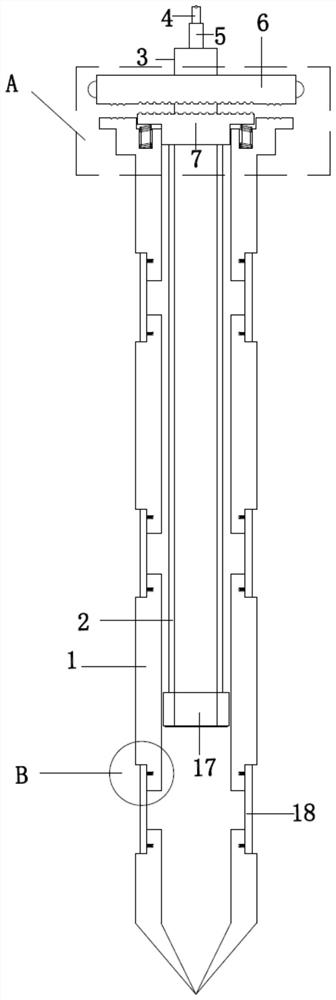

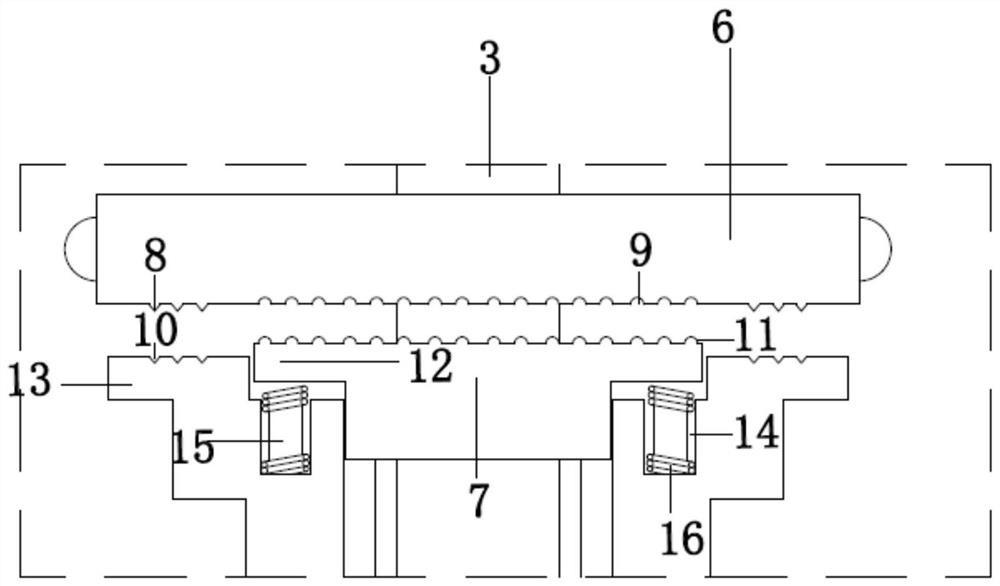

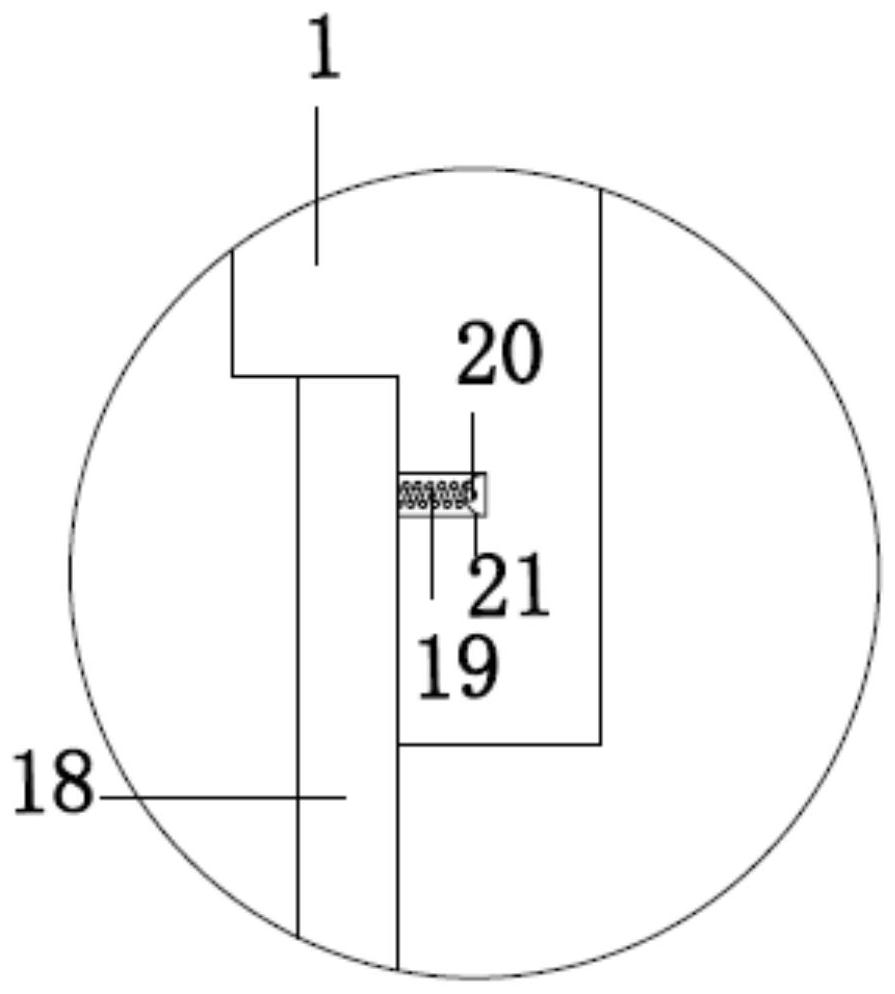

[0036] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0037] A precise grouting water plugging method suitable for silty fine sand and silty clay strata, comprising the following steps:

[0038] After drilling to the design depth, withdraw the drill rod.

[0039] Install the grouting pipe 1 into the drilled hole.

[0040]Multiple groups of slurry holes are arranged along the circumference of the pipe wall at different heights of the grouting pipe 1. According to the different heights and positions of the grouting holes, the grouting process is divided into different engineering sections. The part corresponding to the bottom grouting hole is the first section. The engineering section is numbered from bottom to top. The part corresponding to the grouting hole on the uppermost side is the Nth engineering section. N is a positive integer, and N ≥ 3. The value of N is selected according to the actual needs of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com