Cable detection test system containing harmonic current

A technology of harmonic current and test system, applied in test circuit, test dielectric strength, information technology support system, etc., to achieve the effect of high technical level and comprehensive test ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

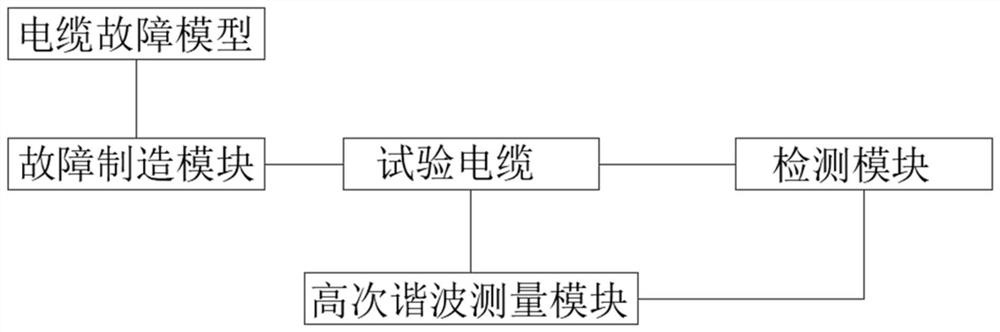

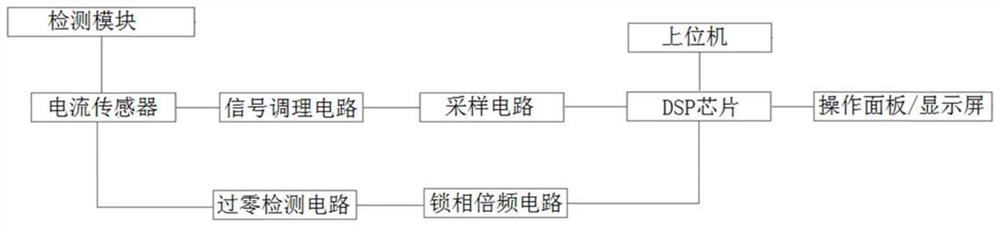

[0033] like figure 1 As shown, this embodiment provides a cable detection test system containing harmonic current, including: a cable fault model, a fault manufacturing module, a high-order harmonic measurement module, a detection module, and a test cable;

[0034] 1. The cable fault model is connected to the fault manufacturing module for simulating the cable model under various faults;

[0035] 2. The fault manufacturing module is connected to the test cable, and is used to simulate various cable faults in reality through the cable fault model on the test cable; the cable fault types include local overheating, partial discharge, water tree, and damage to the protective layer Wait;

[0036] 3. The high-order harmonic measurement module is connected to the test cable, and is used to measure and collect the high-order harmonic characteristic value generated by the test cable under the manufacturing fault of the fault manufacturing module, and according to the high-order harmon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com