Heat exchange device, circulating system and C-shaped arm X-ray machine equipment

A technology of heat exchange device and circulation system, which is applied in cooling/ventilation/heating transformation, medical science, diagnosis, etc., and can solve problems such as insufficient thermal shock resistance and long-term continuous working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

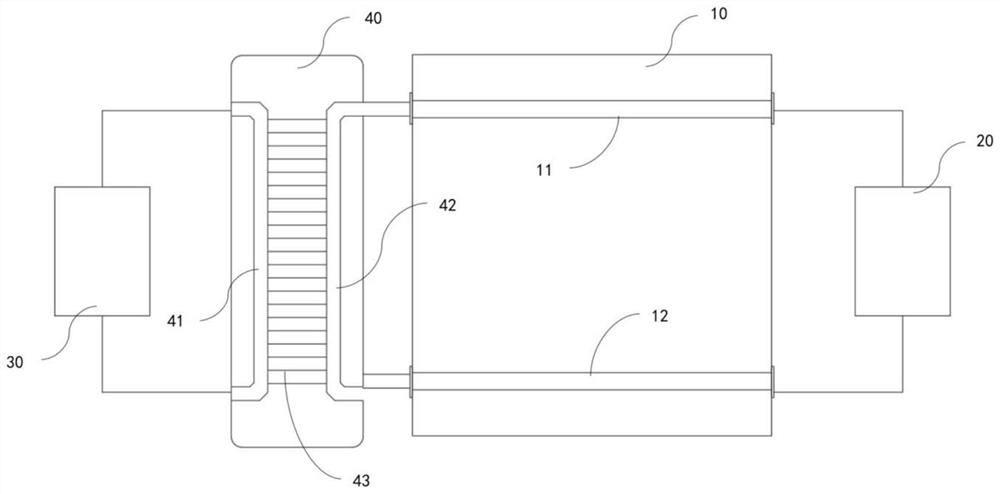

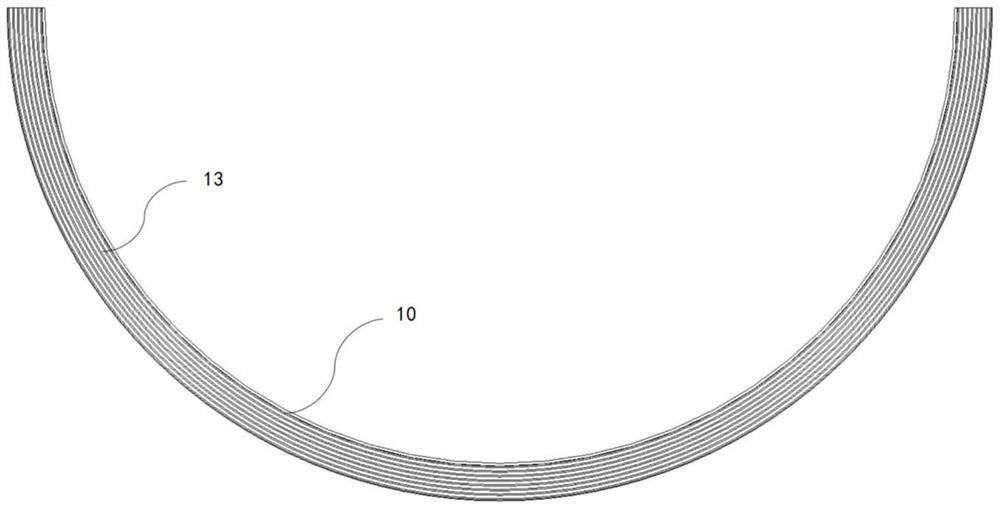

[0049] like figure 1 and figure 2 As shown, this embodiment provides a heat exchange device suitable for radiating heat from a ray source, including a heat exchange structure 40 and a heat dissipation unit, the heat exchange structure 40 includes a first heat exchange channel 41 and a second heat exchange channel 42, The first heat exchange channel 41 is suitable for communication with the heat medium source of the ray source, the first heat exchange channel 41 is sealed with the flow path of the heat medium source, and the first heat exchange channel 41 is used to accommodate the circulating heat medium source, and Heat transfer occurs with the heat medium source circulating therein to absorb the heat of the heat medium source; the heat dissipation unit is communicated with the second heat exchange channel 42, and the heat dissipation unit includes the heat dissipation arm structure 10 and the liquid cooling structure 20. The heat dissipation arm structure 10 has at least t...

Embodiment 2

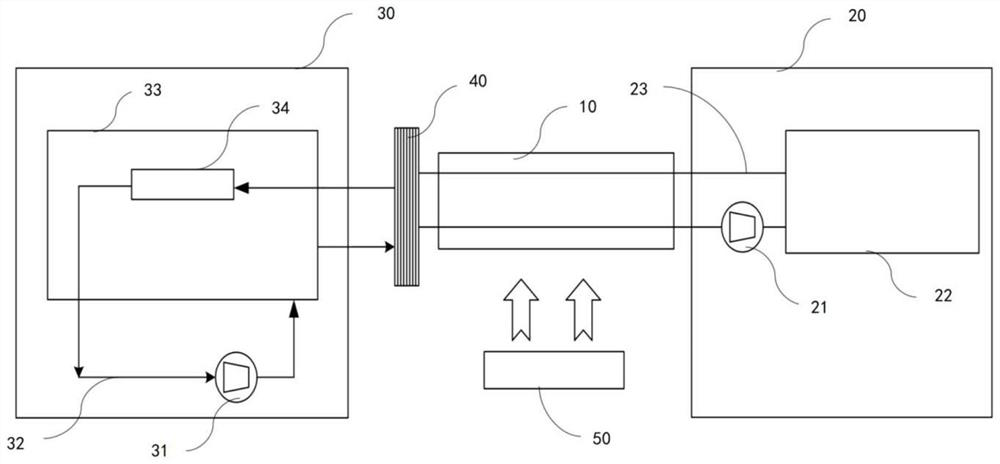

[0059] This embodiment provides a circulation system, including the heat exchange device of Embodiment 1.

[0060] The circulation system provided in this embodiment further includes a circulation mechanism 30, the circulation mechanism 30 includes a second circulation pump 31, a circulation circuit 32, and an oil tank 33, the oil tank 33 is suitable for storing a heat medium source, and the circulation circuit 32 is connected to The first heat exchange channel 41 is in communication, and the second circulation pump 31 is adapted to drive the heat medium source in the oil tank 33 to circulate along the circulation loop 32 and the first heat exchange channel 41 .

[0061] As an implementation of this embodiment, the cooling tank 22 in the liquid cooling structure 20 and the oil tank 33 in the circulation mechanism 30 are arranged on both sides of the heat dissipation arm structure 10 opposite to each other, so as to ensure the thermal shock resistance and longevity of the heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com