UV machine with good cooling effect

A technology of cooling effect and cooling box, applied in the direction of cooling/ventilation/heating transformation, secondary treatment of printed circuit, etc., can solve the problems of general cooling effect, influence of circuit board silk screen, etc., to ensure screen printing quality, better water cooling effect, Better water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Attached to the following Figure 1-5 This application will be described in further detail.

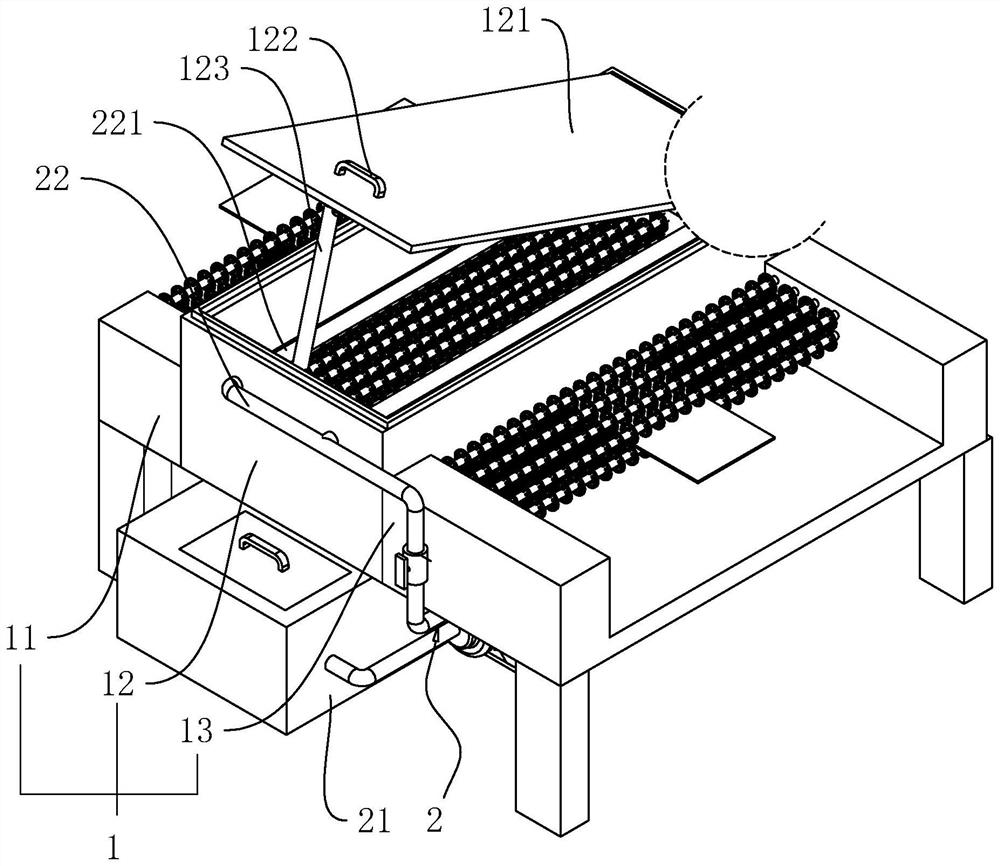

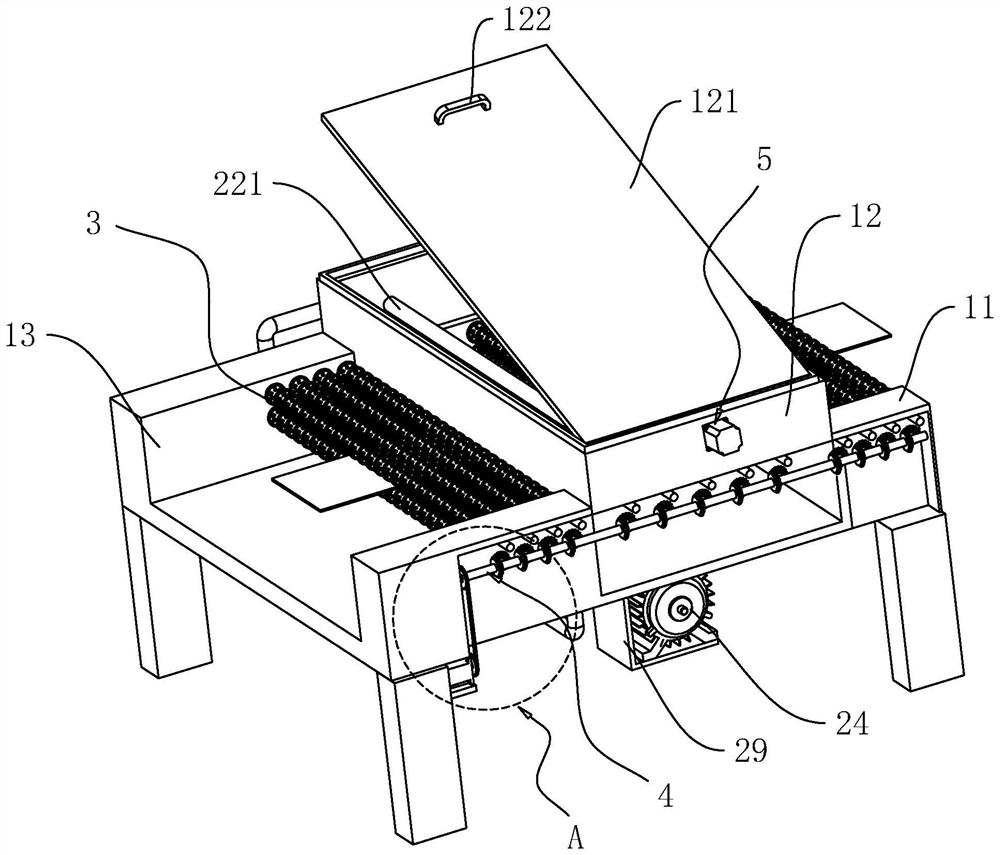

[0037] The embodiment of the present application discloses a UV machine with good cooling effect. refer to figure 1 and figure 2 , the UV machine with good cooling effect includes a rack 1 and a water cooling mechanism 2 arranged on the rack 1. The water cooling mechanism 2 is used to water-cool the circuit board; The cleaning mechanism 5 of the water outlet end of the water cooling mechanism 2 has a better water outlet effect; a conveying mechanism 3 is longitudinally arranged in the frame 1; 3. A drive mechanism 4 capable of conveying the circuit board.

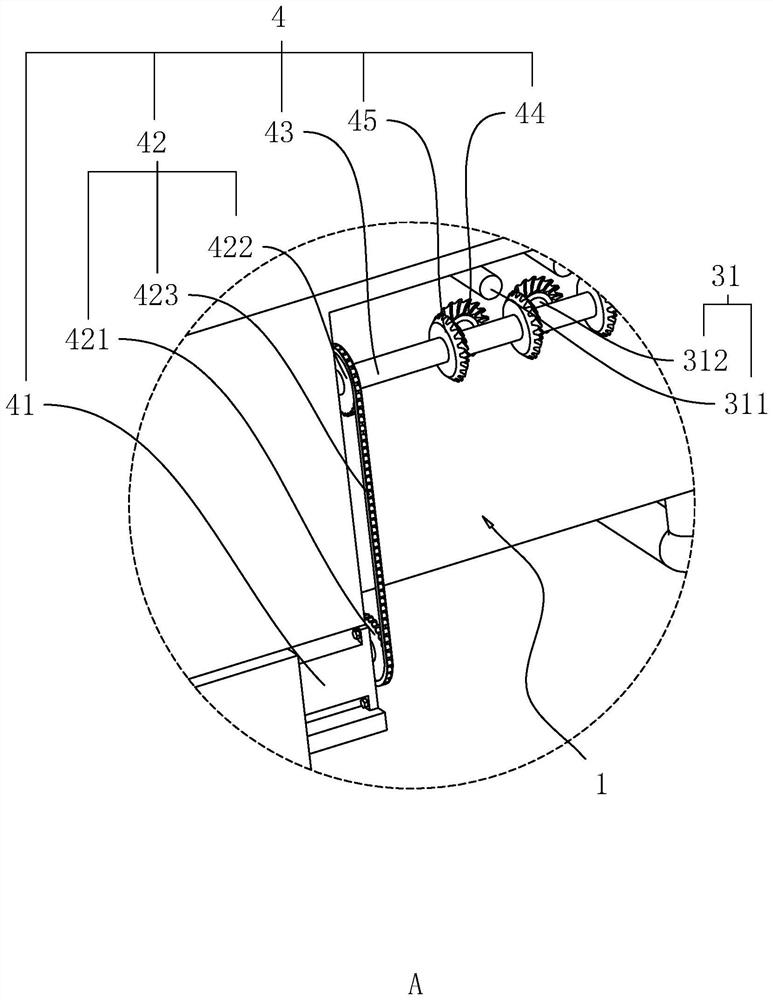

[0038] refer to figure 2 and image 3 , the conveying mechanism 3 includes a plurality of groups of conveying roller groups 31 longitudinally arranged in the frame 1 and rotatably connected to the frame 1, and the plurality of groups of conveying roller groups 31 are distributed in the frame 1 at equal intervals alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com