Automatic fire extinguisher production line

A fire extinguisher, fully automatic technology, applied in fire rescue, chemical instruments and methods, progressive dryers, etc., can solve problems affecting production, unreasonable fire extinguisher production line technology, difficult adjustment, etc., to improve work efficiency and eliminate movement and the effect of not being able to transmit normally and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

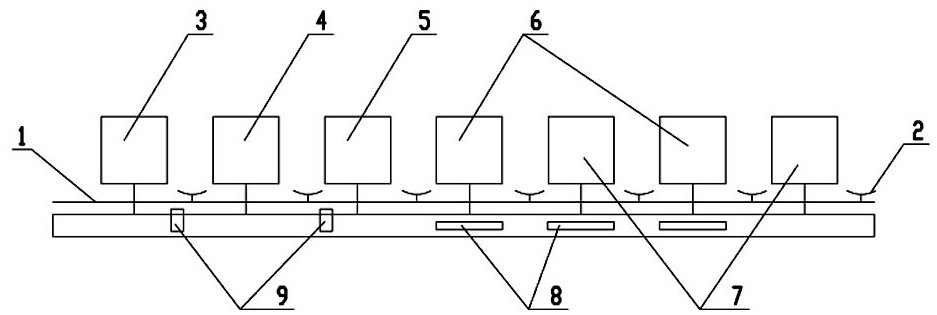

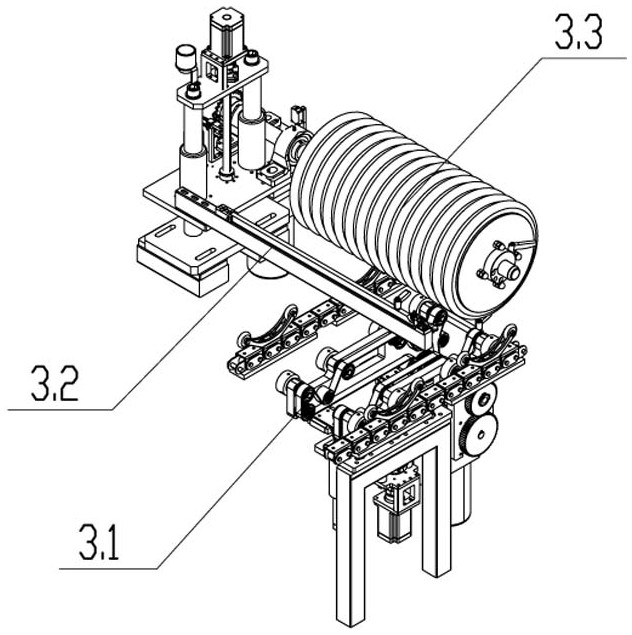

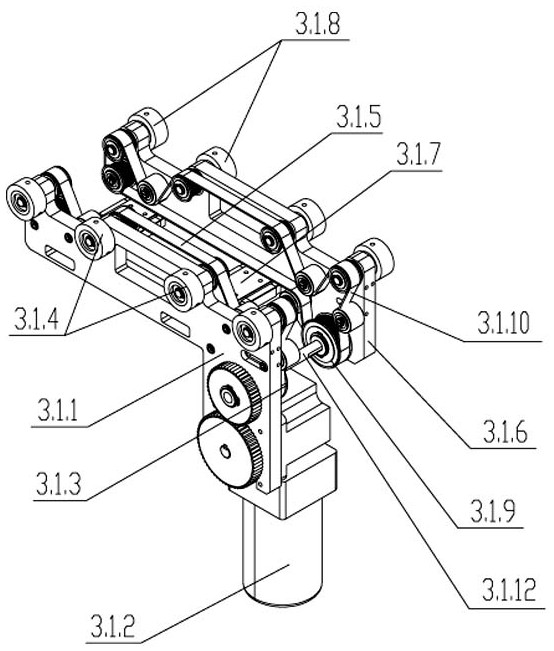

[0035] Such as figure 1As shown, the automatic fire extinguisher production line of the present invention includes a frame and a conveying chain 1 arranged longitudinally along the frame, a transverse distance adjustment mechanism is arranged between the conveying chains 1, and intervals for supporting fire extinguishers are arranged on the conveying chain 1. The roller bracket 2, along the transmission direction of the conveyor chain 1, is sequentially provided with a water removal and dust removal device 3 connected to the frame, a drying box 4, a dust removal hair wheel device 5, and at least one set behind the dust removal hair wheel device 5. A silk screen drying device, the screen printing drying device includes a screen printing device 6 and a UV light curing device 7 , and a handle guide 8 is provided on one side frame of the drying box 4 and the UV light curing device 7 .

[0036] In the original production line, the fire extinguisher directly enters the screen printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com