Resin composition having excellent recoverability and multilayer structure using same

A resin composition and multi-layer structure technology, applied in recycling technology, synthetic resin layered products, packaging recycling, etc., can solve the problems of adhesion of deteriorated products, insufficient impact resistance, difficult continuous melt forming, etc. Good melt formability and excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0105] Hereinafter, the present invention will be described in more detail using examples, but the present invention is not limited to these examples.

[0106]

[0107] (1) MFR

[0108] For resins used in Examples and Comparative Examples, MFR (g / 10 minutes) was measured using a melt index meter in accordance with JIS K 7210:2014. The temperature and load vary according to the kind of resin.

[0109] (2) Glass transition temperature

[0110] For resins used in Examples and Comparative Examples, using RHEOGEL E 4000 manufactured by UBM, the glass transition temperature was measured under the following conditions by a dynamic viscoelasticity measurement method. In addition, the peak temperature of Tan (delta) was made into glass transition temperature.

[0111] Temperature range: -100℃~+40℃

[0112] Heating rate: 3°C / min (step size 3°C)

[0113] Fundamental frequency: 11Hz (sine wave)

[0114] Clamp Gap: 20mm

[0115] Test piece size: width 5 mm, thickness 200 μm, lengt...

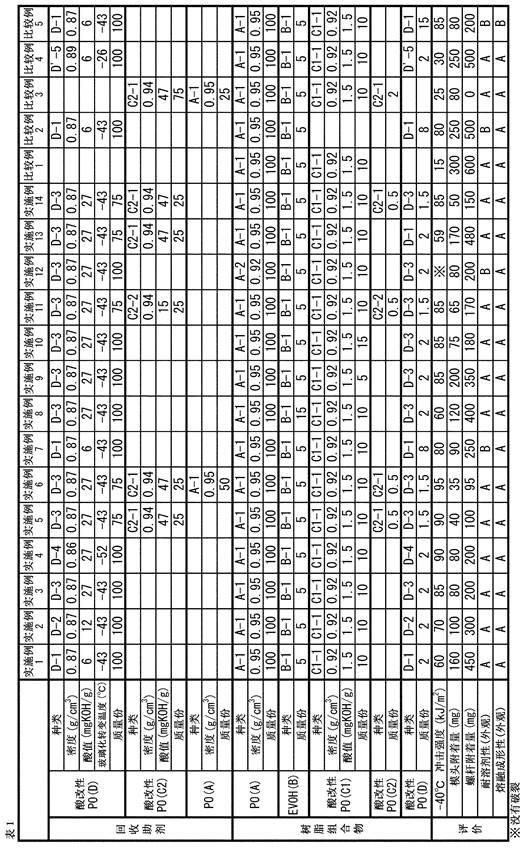

Embodiment 2~12、 comparative example 1~5

[0184] Except that the types of PO (A), EVOH (B), acid-modified PO (C) and acid-modified PO (D) and the amounts of each component were changed as described in Table 1, the same 1 The recovery aid and resin composition pellets were prepared and evaluated in the same manner. The evaluation results are shown in Table 1. It should be noted that, in the case of blending a plurality of resins with the recovery aid, after dry blending in advance, granulation was performed under the same conditions as in Example 1 to prepare the recovery aid.

Embodiment 13

[0186] Using PO (A-1), EVOH (B-1), and acid-modified PO (C1-1), extruded at 210°C using a blow molding machine "TB-ST-6T" manufactured by Suzuki Works (inside) PO(A-1) layer / acid-modified PO(C1-1) layer / EVOH(B-1) layer / acid-modified PO(C1-1) layer / PO(A-1) layer (outside) 3 types 5-layer parison, blow-molded in a mold at 15°C, cooled for 20 seconds, and the entire layer thickness was 3450 μm [(inside) PO (A-1) layer / acid-modified PO (C1-1) layer / EVOH (B- 1) A 500 ml container of layer / acid-modified PO(C1-1) layer / PO(A-1) layer (outside)=1500 / 150 / 150 / 150 / 1500] was formed. After the obtained container was pulverized, 2 parts by mass of the recovery aid (particles of acid-modified PO (D-1)) produced in Example 1 was added to 115 parts by mass of the obtained pulverized product, and the same method as in Example 1 was used. Method Resin composition pellets were produced and evaluated. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com