Polyoxamide resin having excellent impact resistance and impact-resistant part

A polydiacetamide, impact resistance technology, applied in the field of parts and components, to achieve the effects of excellent melt formability, excellent oxidation resistance, and excellent resistance to ethanol penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] As the oxalic acid source used in the preparation of the polydiacetamide of the present invention, oxalic acid diester is used, as long as it has reactivity with the amino group, it is not particularly limited, for example, dimethyl oxalate, dioxalate Oxalic acid diesters of aliphatic monohydric alcohols such as ethyl ester, di-n-(or iso)propyl oxalate, di-n-(or iso-, t-)-butyl oxalate, etc., oxalic acid diesters of alicyclic alcohols such as dicyclohexyl oxalate Oxalic acid diesters of aromatic alcohols such as phenyl esters, etc.

[0036] Among the above-mentioned oxalic acid diesters, oxalic acid diesters of aliphatic monohydric alcohols with more than 3 carbon atoms, oxalic acid diesters of alicyclic alcohols, and oxalic acid diesters of aromatic alcohols are preferred, among which dibutyl oxalate and dibutyl oxalate are particularly preferred. phenyl esters.

[0037] As the diamine component, a diamine having 10 to 18 carbon atoms is used. Plant-derived diamines ...

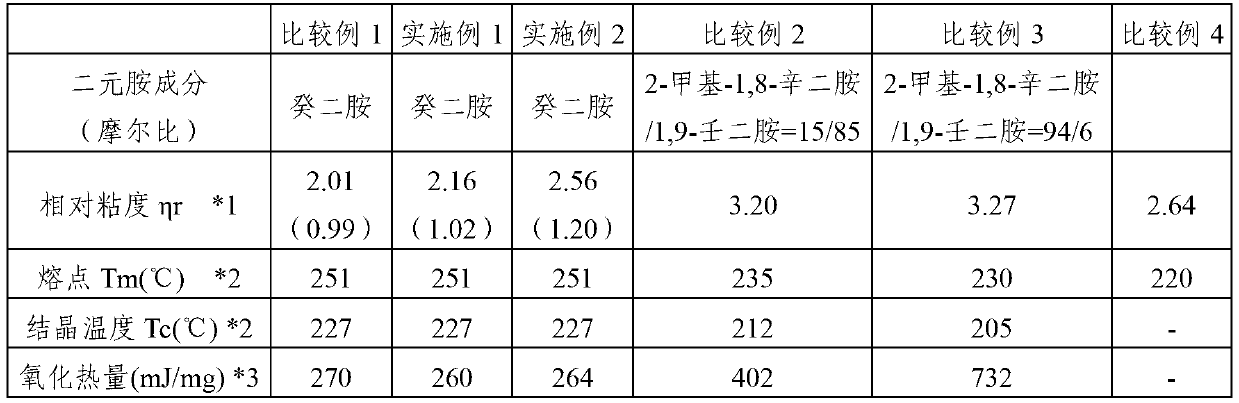

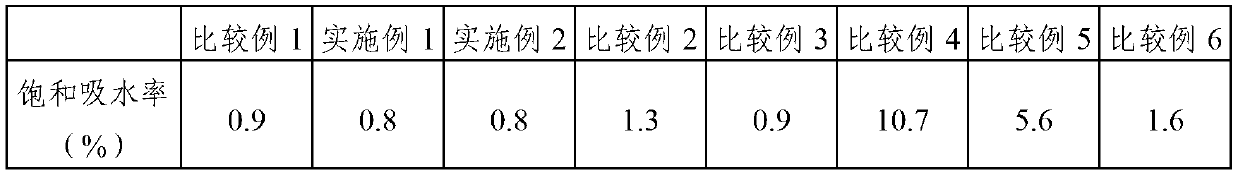

Embodiment 1)

[0089] (i) Pre-polycondensation process: Add 875.0g (5.0809 mol) 1,10-decanediamine from plants, the raw material inlet is directly connected to the raw material feed pump through a pipe with a diameter of 1 / 8 inches, and 875.0 g (5.0809 moles) from For plant 1,10-decanediamine, pressurize the pressure vessel to 3.0 MPa with nitrogen gas with a purity of 99.9999%, then discharge the nitrogen gas to normal pressure, repeat this operation 5 times, and then treat the system under confining pressure Warm up inside. After bringing the internal temperature to 190° C. over 20 minutes, 1,027.6 g (5.0808 mol) of dibutyl oxalate was injected into the reaction vessel from a raw material feed pump at a flow rate of 65 ml / min over about 17 minutes. The internal pressure in the pressure-resistant container immediately after the entire amount was injected rose to 0.65 MPa due to 1-butanol produced by the polycondensation reaction, and the internal temperature rose to 197°C.

[0090] (ii) F...

Embodiment 2)

[0093] (i) Pre-polycondensation process: Add 875.05g (5.0812mol) to a 5L pressure-resistant container equipped with a stirrer, thermometer, torque meter, pressure gauge, nitrogen gas inlet, pressure release port, polymer outlet and raw material inlet 1,10-decanediamine from plants, the raw material input port is directly connected to the raw material feed pump through a pipe with a diameter of 1 / 8 inch, and the pressure-resistant container is pressurized to 3.0 MPa with nitrogen with a purity of 99.9999% After that, the nitrogen gas was discharged to normal pressure, and this operation was repeated 5 times, and then the temperature in the system was raised under the confining pressure. After the internal temperature reached 190° C. over 20 minutes, 1027.14 g (5.0812 mol) of dibutyl oxalate was injected into the reaction vessel through the raw material feed pump at a flow rate of 65 ml / min over about 17 minutes while raising the temperature. The internal pressure in the pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com