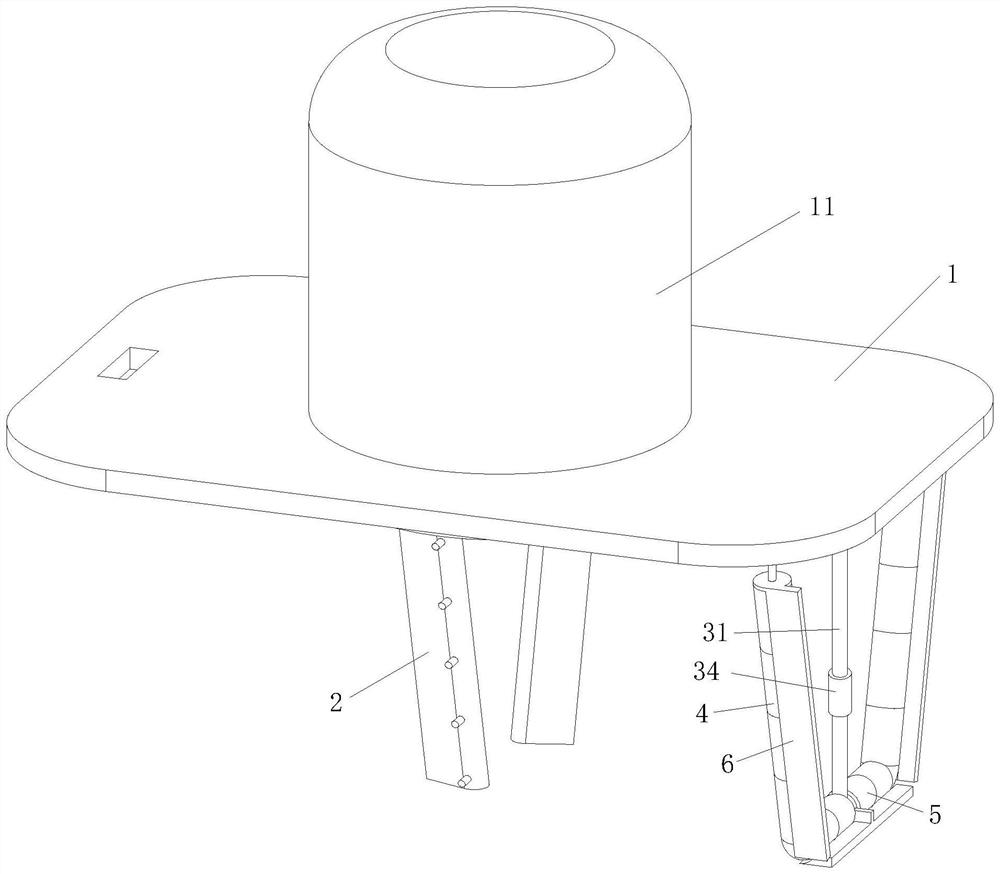

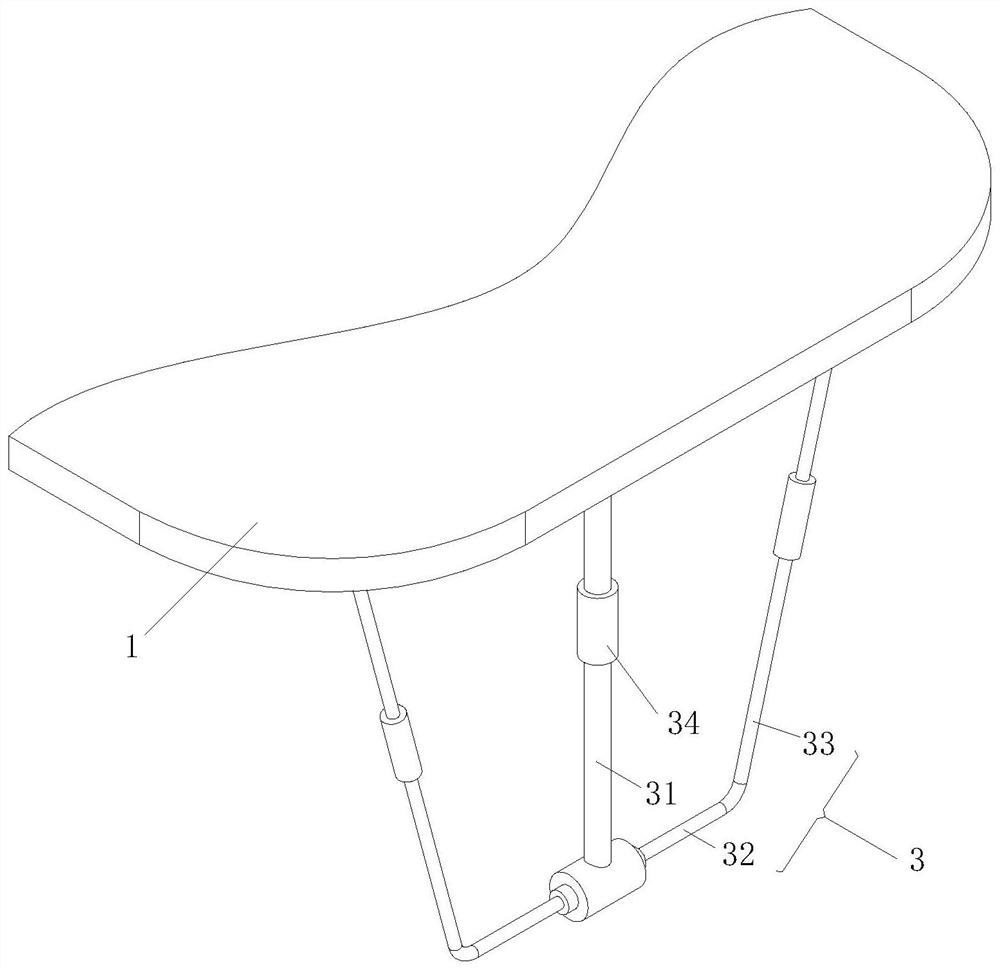

Small gardening ditcher

A ditching machine and horticultural technology, applied in the fields of excavation/covering ditches, planting methods, agriculture, etc., can solve the problems of ditch stereotypes, easy collapse of the side walls of the ditch, and influence on use, so as to ensure the shaping effect and guarantee The effect of ditching quality and maintenance cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

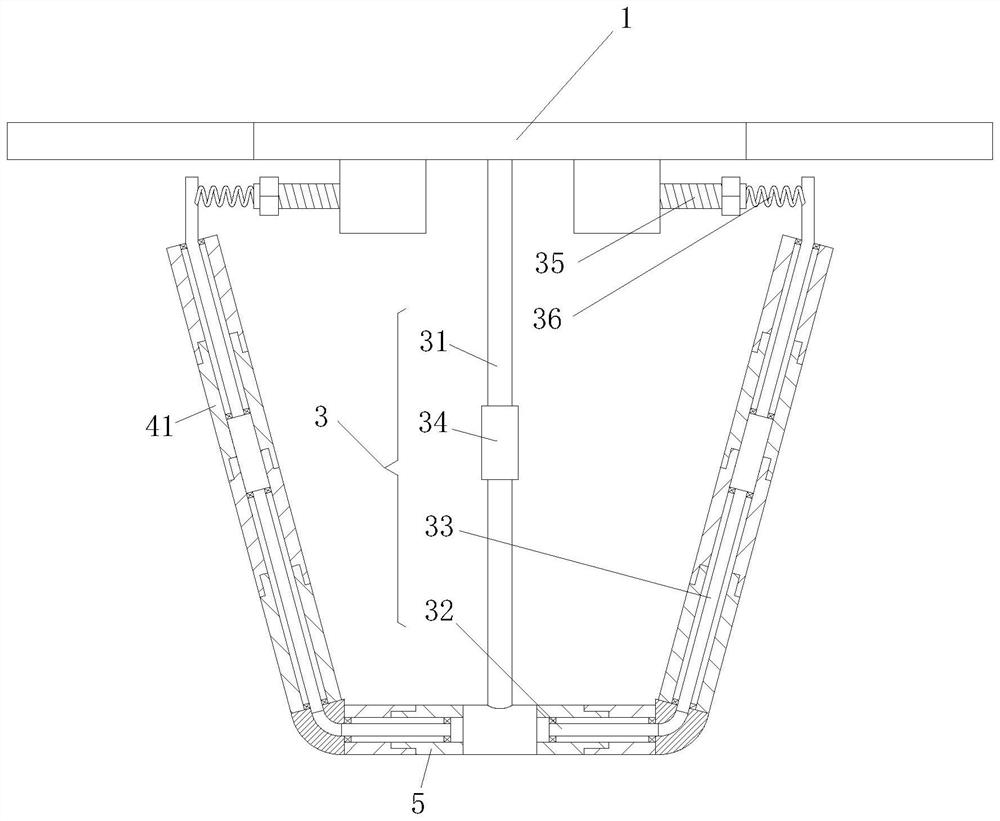

[0046] As an embodiment of the present invention, the collars 41 are connected by snaps.

[0047] When working, the forming roller 4 and the flat bottom roller 5 are connected by the sleeve ring 41. During the use, the local position of the forming roller 4 or the flat bottom roller 5 will be worn out, but other positions will not affect the use. Remove the roller 5, then replace the collar 41 at the worn position, and then install the shaping roller 4 or the flat bottom roller 5 back, without replacing the entire shaping roller 4 or the flat bottom roller 5, saving maintenance costs and ensuring the shaping roller 4 or the shaping effect of the flat bottom roller 5 on the ditch, reducing the possibility of ditch collapsing and improving the stability of the ditch in use, and the collars 41 are connected by threads or snaps, which are convenient for disassembly and installation, and easy for maintenance.

[0048] As an embodiment of the present invention, such as image 3 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com