Automatic overturning baking oven tobacco leaf stable conveying structure

A technology of automatic overturning and baking oven, which is applied to conveyors, tobacco, tobacco preparation, etc., can solve the problems of cumbersome and laborious operation, and achieve the effects of avoiding falling, simplifying loading steps, and convenient and labor-saving use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

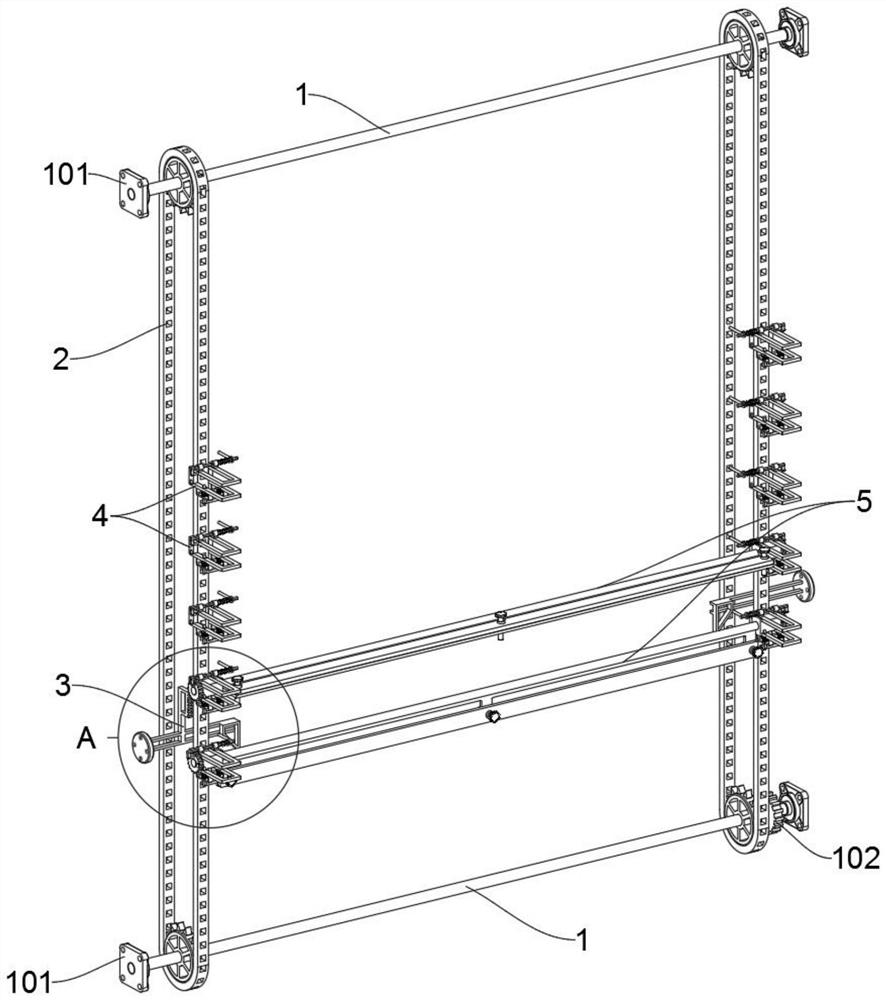

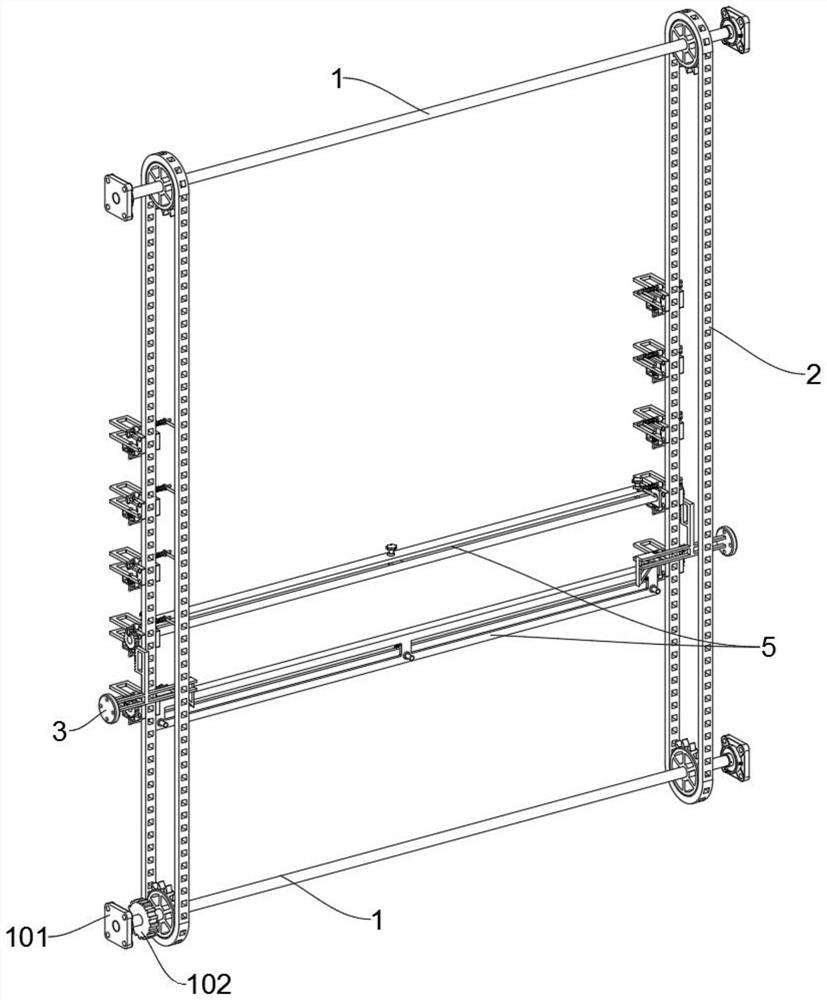

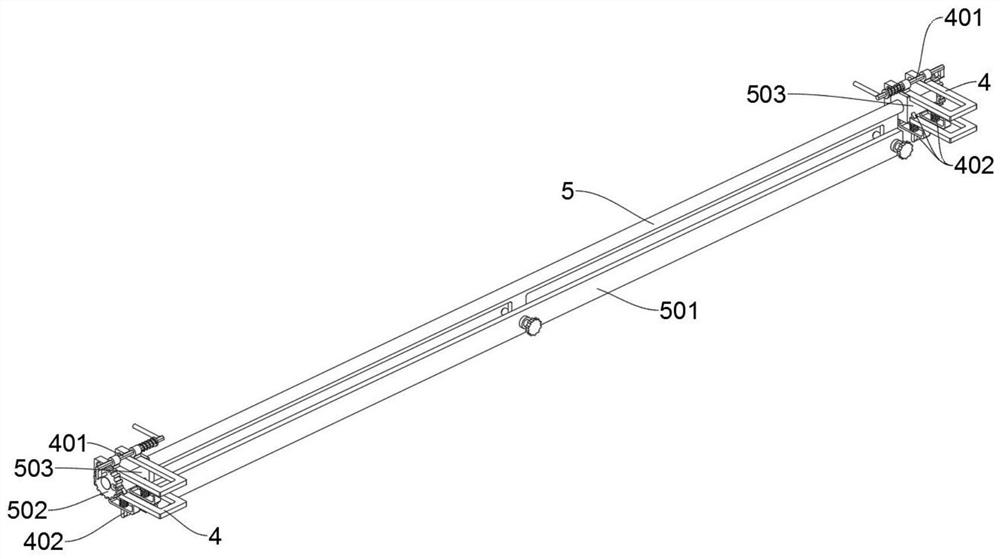

[0038] see Figure 1 to Figure 10 , an embodiment provided by the present invention: an automatic reversing structure for stably conveying tobacco leaves in a roasting furnace, comprising a wheel shaft 1; the wheel shaft 1 includes a bearing seat 101, and the two ends of the wheel shaft 1 are symmetrically sleeved with two square squares The bearing seat 101, the two axles 1 are locked and fixed on the left and right side walls of the smoke drying furnace through the bearing seats 101 at both ends thereof, and the left and right end sections of the two axles 1 are symmetrically sleeved with four sprockets. Two chains 2 are supported and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com