Reverse supply steam pressurization regulation and control system and method self-adaptive to working conditions

A control system, self-adaptive technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of energy loss, atmospheric environmental pollution, working medium loss, etc., and achieve good economic and social benefits, The effect of reducing the difficulty of regulation and increasing the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

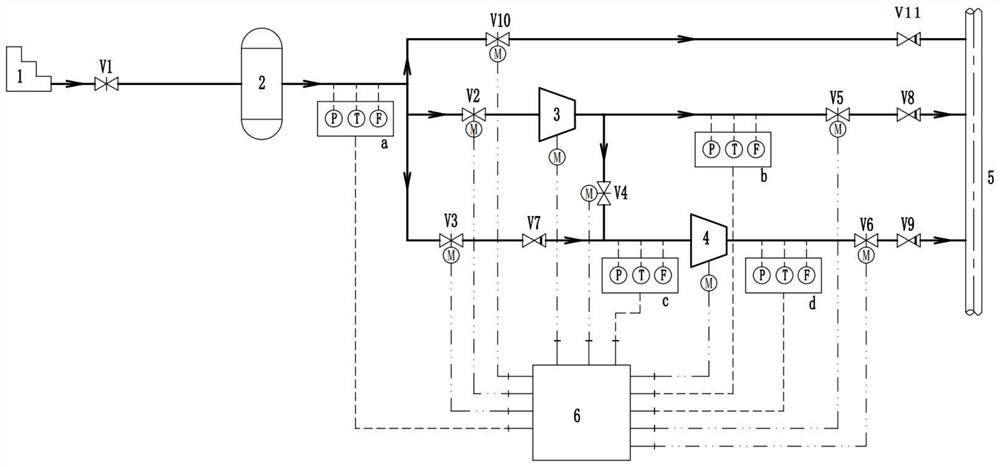

[0056] like figure 1 As shown in the figure, this embodiment provides a back-feed steam pressurization control system adaptive to working conditions, including a back-feed steam heat source 1, a steam surge tank 2, a first steam compressor 3, a second steam compressor 4, a Hot steam pipe network 5, data acquisition control center 6.

[0057] The reverse steam supply heat source 1 can output waste heat steam with large fluctuations in pressure, temperature and flow rate. The heat source includes but is not limited to the steam produced by the waste heat boiler of the industrial factory or the exhausted steam of the industrial factory process. The characteristic of this type of heat source is that the supplied steam can be used for It is a supplement to industrial heating, so it is called reverse steam supply, but the steam source parameters fluctuate greatly and the stability is very poor. Most of the time, the steam parameters do not meet the requirements of the heating pipe n...

Embodiment 2

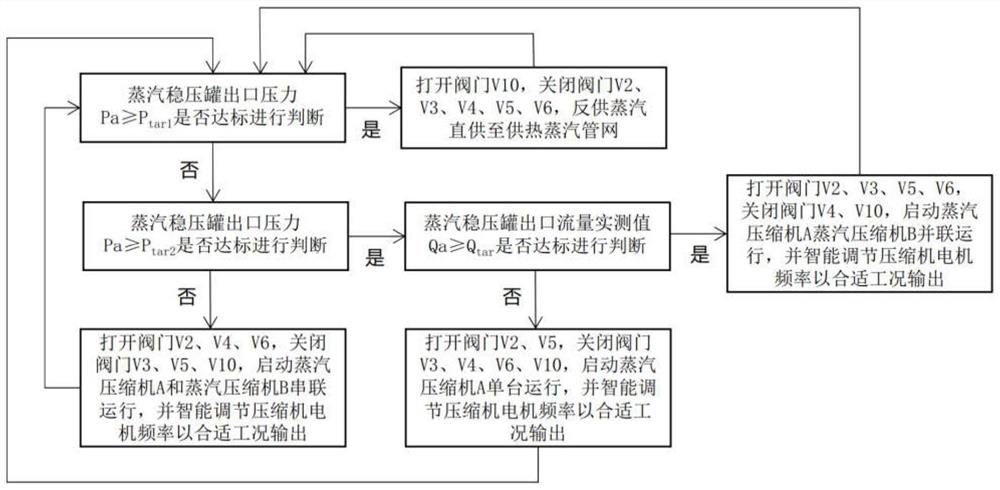

[0075] like figure 2 As shown in the figure, a control method of a reverse steam supply pressurization system adaptive to working conditions includes:

[0076] Step S1, establishing the operation module of the reverse steam pressurization system;

[0077] Step S2, establishing the operation judgment module of the reverse supply steam pressurization system for the operation module of the reverse supply steam pressurization system established in step S1; based on the pressure of the heat supply pipe network, set the first target value P of the outlet pressure of the steam surge tank tar1 , obtain the measured value Pa of the outlet pressure of the steam surge tank, and judge whether the outlet pressure of the steam surge tank meets the standard, if Pa ≥ P tar1 If it reaches the standard, go to step S3; if it does not meet the standard, go to step S4;

[0078] Step S3, establish a direct supply module for reverse steam supply, open valve V10, close valves V2, V3, V4, V5, V6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com